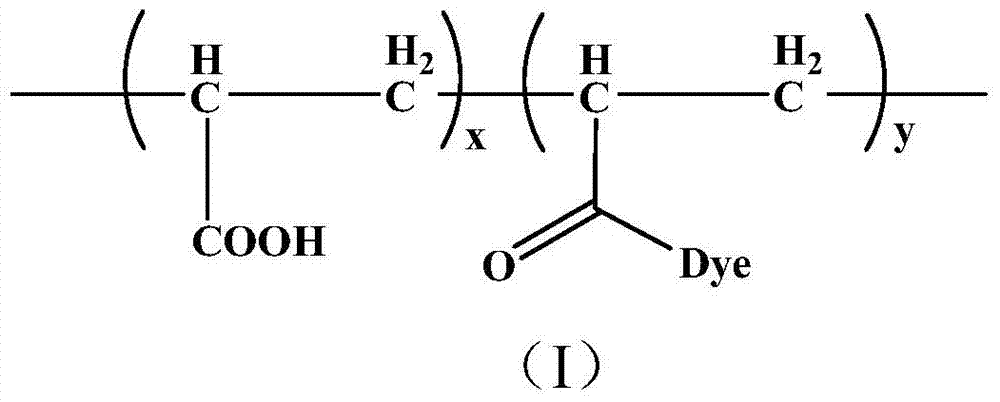

Pigment dye solution for dyeing superfine fiber and method for improving color depth of superfine fiber dyeing

A technology for dyeing superfine fibers and paints, which is applied to the fields of paint dye liquors for superfine fibers, paint dyes for dyeing superfine fibers and improving the color depth of superfine fiber dyeing. Increase dyeing energy consumption and other issues to achieve the effect of simple dyeing process, stable product quality and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

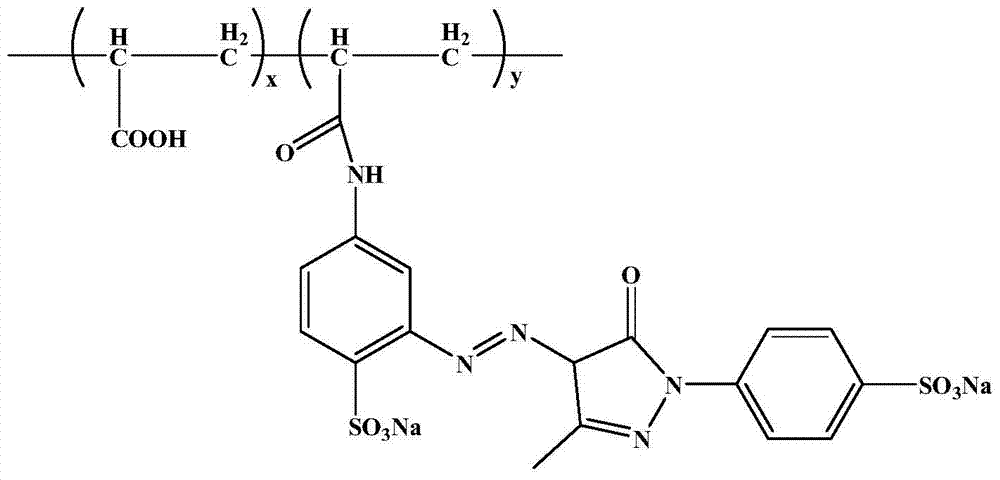

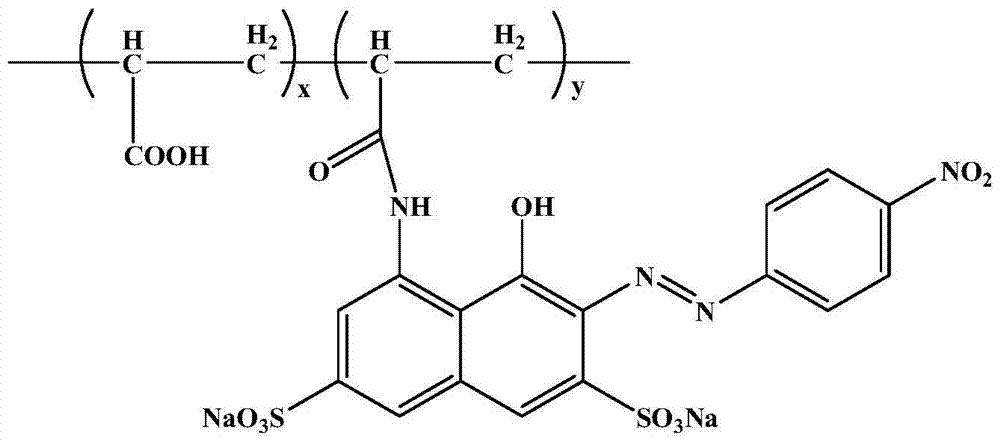

Method used

Image

Examples

Embodiment 1

[0039] (1) Padding paint dye solution: immerse the microfiber in the paint dye solution at a temperature of 40°C for 10 minutes, then pad the paint dye solution once on a paddle car, and control the excess rate of 50%. Among them, the paint dye solution contains the following components: color paste TSE R0772 is 10g / L, acrylic macromolecular dye A 1g / L, binder is 40g / L, penetrant is 0.5g / L; (2) pre-baking : Pre-bake at 60°C for 5 minutes; (3) Baking: bake at 120°C for 5 minutes.

Embodiment 2

[0041] (1) Padding paint dye solution: immerse the superfine fiber in the paint dye solution at a temperature of 60°C for 5 minutes, and then pad the paint dye solution twice on a paddle car to control the excess rate of 70%. Among them, the paint dye solution contains the following components: color paste TSE R0871 is 25g / L, acrylic macromolecular dye B 2.5g / L, binder is 100g / L, and penetrant is 1g / L; (2) pre-baking : Pre-bake for 4 minutes at a temperature of 70°C; (3) Baking: bake for 3 minutes at 140°C.

Embodiment 3

[0043] (1) Padding paint dye solution: immerse the superfine fiber in the paint dye solution with a temperature of 80°C for 2 minutes, then pad the paint dye solution 3 times on the paddle car, and control the excess rate of 80%. Among them, the paint dye solution contains the following components: color paste TSE R0873 is 50g / L, acrylic macromolecular dye C 5g / L, binder is 200g / L, and penetrant is 2g / L; (2) pre-baking: Pre-bake at 90°C for 3 minutes; (3) Baking: bake at 150°C for 2 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com