A method of dyeing with natural dyes

A technology of natural dyes and dyes, applied in the field of dye dyeing, can solve the problems such as the reduction of dye fixation, and achieve the effects of improving color fastness to rubbing, improving utilization rate, and improving color fastness to water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

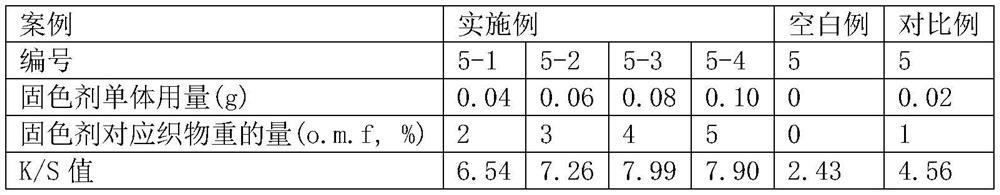

Examples

Embodiment 1

[0034] Example 1: Comparison of dyeing methods

[0035] 0.06 g (3% o.m.f) gardenia yellow natural plant dye and 0.08 g (4% o.m.f) methylene double acrylamide chromoside monomer, dissolved in 3 ml (150% o.m.f) water, formulated into a high concentration Gardenia yellow natural plant dye - solid toner monomer solution.

[0036] Each 5 g of the surfactant Aeo-3 and the surfactant were orthodontically octanol, stirred to a uniform, formulated auxiliary solution. The solution of 2.5 g of the formulated auxiliary solution was taken to 100 ml, stirred to uniform, and prepared as a silicon-based auxiliary solution.

[0037] The silicon base aiding solution was added to the aforementioned 3 ml of a gardenlin natural plant dye-solid chromorative monomer solution until the total volume of the solution reached 40 mL, stirred to uniform, and the contamination was obtained.

[0038] 2 g of cotton cloth was immersed in 40 mL of dye (1:20 in the bath), 70 min was dipped at 90 ° C. After the dissip...

Embodiment 2-1

[0046] Example 2-1: Effect of moisture content

[0047] 0.06 g (3% o.m.f) gardenia yellow natural plant dye and 0.08 g (4% o.m.f) methylene double acrylamide solid chromoracic monomer, dissolved in 1 ml (50% o.m.f) water, formulated into a scorpion Yellow natural plant dye - solid toner monomer solution.

[0048] Each 5 g of the surfactant Aeo-3 and the surfactant were orthodontically octanol, stirred to a uniform, formulated auxiliary solution. The solution of 2.5 g of the formulated auxiliary solution was taken to 100 ml, stirred to uniform, and prepared as a silicon-based auxiliary solution.

[0049] The silicon base aiding solution was added to the aforementioned 1 ml of a gardenlin natural plant dye-solid chromothel monomer solution until the total volume of the solution reached 40 ml, stirred to uniform, and the contamination was obtained.

[0050] 2 g of cotton cloth was immersed in 40 mL of dye (1:20 in the bath), 70 min was dipped at 90 ° C. After the dissipation was comp...

Embodiment 2-2、2-3、2-4 and 2-5

[0052] Based on Example 2-1, 2 mL (100% o.m.f), 3 mL (150% o.m.f), 4 ml (200% O.M.F) and 5 mL (250% o.m.f) water were used to prepare a dye-solid monomer solution, Other conditions are unchanged. The k / s value of the dyed cotton is listed in Table 2.

[0053] Effect of Table 2 Moisture Content on the K / S value of the chromosome

[0054] Example 2-1 2-2 2-3 2-4 2-5 Water content (ml) 1 2 3 4 5 Water corresponding to the amount of fabric (O.M.F,%) 50 100 150 200 250 K / S value 6.67 7.44 7.99 7.63 7.46

[0055] Table 2 shows that as the moisture content increases, the K / S is first rising, and the maximum is reached when the water content is 150% o.m.f.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com