A method for improving the dyeing performance of nylon 6 fishing net

A dyeing performance, nylon technology, applied in the field of fishing net dyeing, can solve the problems of shallow dyeing degree, low dyeing amount, general dyeing performance of nylon 6 fishing net, etc., to achieve improved dyeing performance, good dyeing fastness, and increased dyeing amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

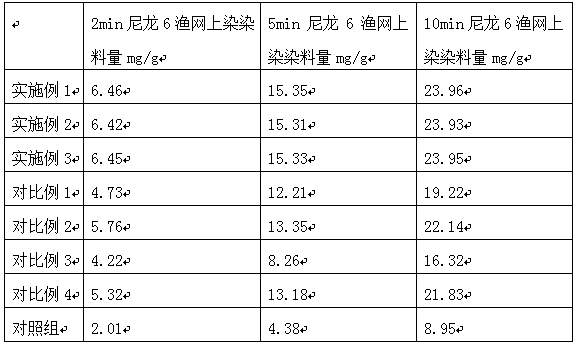

Examples

Embodiment 1

[0014] A method for improving the dyeing performance of nylon 6 fishing nets. After the nylon 6 masterbatches are activated, the activated nylon 6 masterbatches are made into nylon 6 fishing nets, and then the prepared nylon 6 fishing nets are preheated. The preheated nylon 6 fishing net is then subjected to low-temperature plasma treatment, then soaked in grape seed extract, and then dried to carry out dyeing treatment.

[0015] The activation treatment of the nylon 6 masterbatch is specifically: uniformly mix the nylon 6 masterbatch and deionized water in a mass ratio of 1:12, then add aluminum potassium sulfate with a mass of 1.2% of the nylon 6 masterbatch, add it to the mixer Stir at 1200r / min for 40min, then use ammonia water to adjust the pH of the suspension to 8.8, heat to 90°C, stir at 120r / min for 30min, use 350W ultrasonic treatment for 10min, and then add nylon 6 masterbatch mass of 0.08% Ammonium persulfate, after stirring evenly, keep warm at 72°C for 15min, the...

Embodiment 2

[0022] A method for improving the dyeing performance of nylon 6 fishing nets. After the nylon 6 masterbatches are activated, the activated nylon 6 masterbatches are made into nylon 6 fishing nets, and then the prepared nylon 6 fishing nets are preheated. The preheated nylon 6 fishing net is then subjected to low-temperature plasma treatment, then soaked in grape seed extract, and then dried to carry out dyeing treatment.

[0023] The activation treatment of the nylon 6 masterbatch is specifically: uniformly mix the nylon 6 masterbatch and deionized water in a mass ratio of 1:15, then add aluminum potassium sulfate with a mass of 1.2% of the nylon 6 masterbatch, add it to the mixer Stir at 1200r / min for 40min, then use ammonia water to adjust the pH of the suspension to 9.2, heat to 90°C, stir at 120r / min for 30min, use 350W ultrasonic treatment for 12min, then add nylon 6 masterbatch with 0.08% mass Ammonium persulfate, after stirring evenly, keep warm at 72°C for 18min, then ...

Embodiment 3

[0030] A method for improving the dyeing performance of nylon 6 fishing nets. After the nylon 6 masterbatches are activated, the activated nylon 6 masterbatches are made into nylon 6 fishing nets, and then the prepared nylon 6 fishing nets are preheated. The preheated nylon 6 fishing net is then subjected to low-temperature plasma treatment, then soaked in grape seed extract, and then dried to carry out dyeing treatment.

[0031] The activation treatment of the nylon 6 masterbatch is specifically: uniformly mix the nylon 6 masterbatch and deionized water in a mass ratio of 1:14, then add aluminum potassium sulfate with a mass of 1.2% of the nylon 6 masterbatch, add it to the mixer Stir at 1200r / min for 40min, then use ammonia water to adjust the pH of the suspension to 9.0, heat to 90°C, stir at 120r / min for 30min, use 350W ultrasonic treatment for 11min, then add nylon 6 masterbatch with 0.08% mass Ammonium persulfate, after stirring evenly, keep warm at 72°C for 16min, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com