Method for preparing wool reactive-dye brilliant blue

A technology of reactive dyes and temperature control for wool, applied in reactive dyes, azo dyes, organic dyes, etc., can solve the problems of low color yield, large consumption of raw materials, dust pollution, etc., achieve good reproducibility, reduce raw materials Consumption, the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

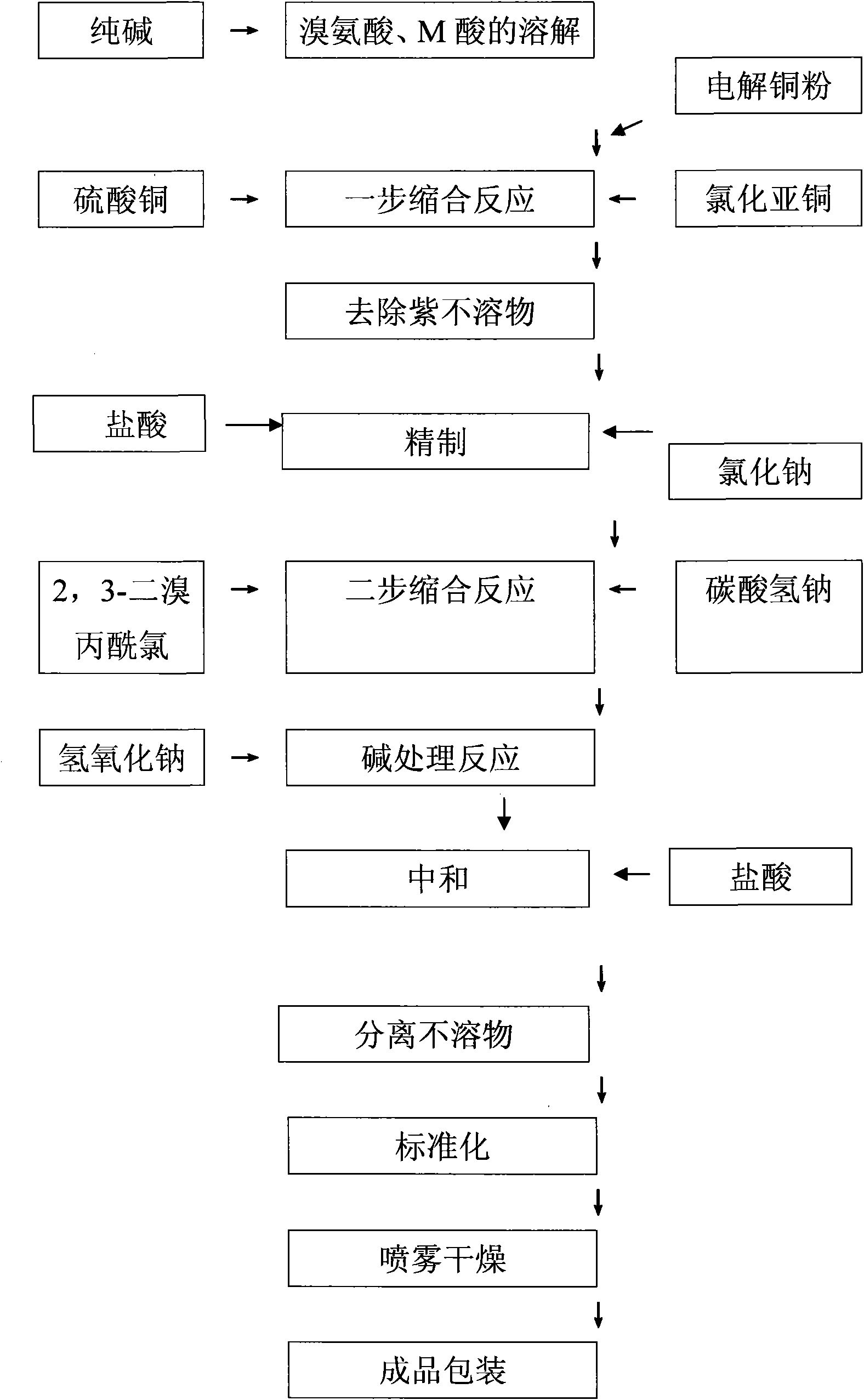

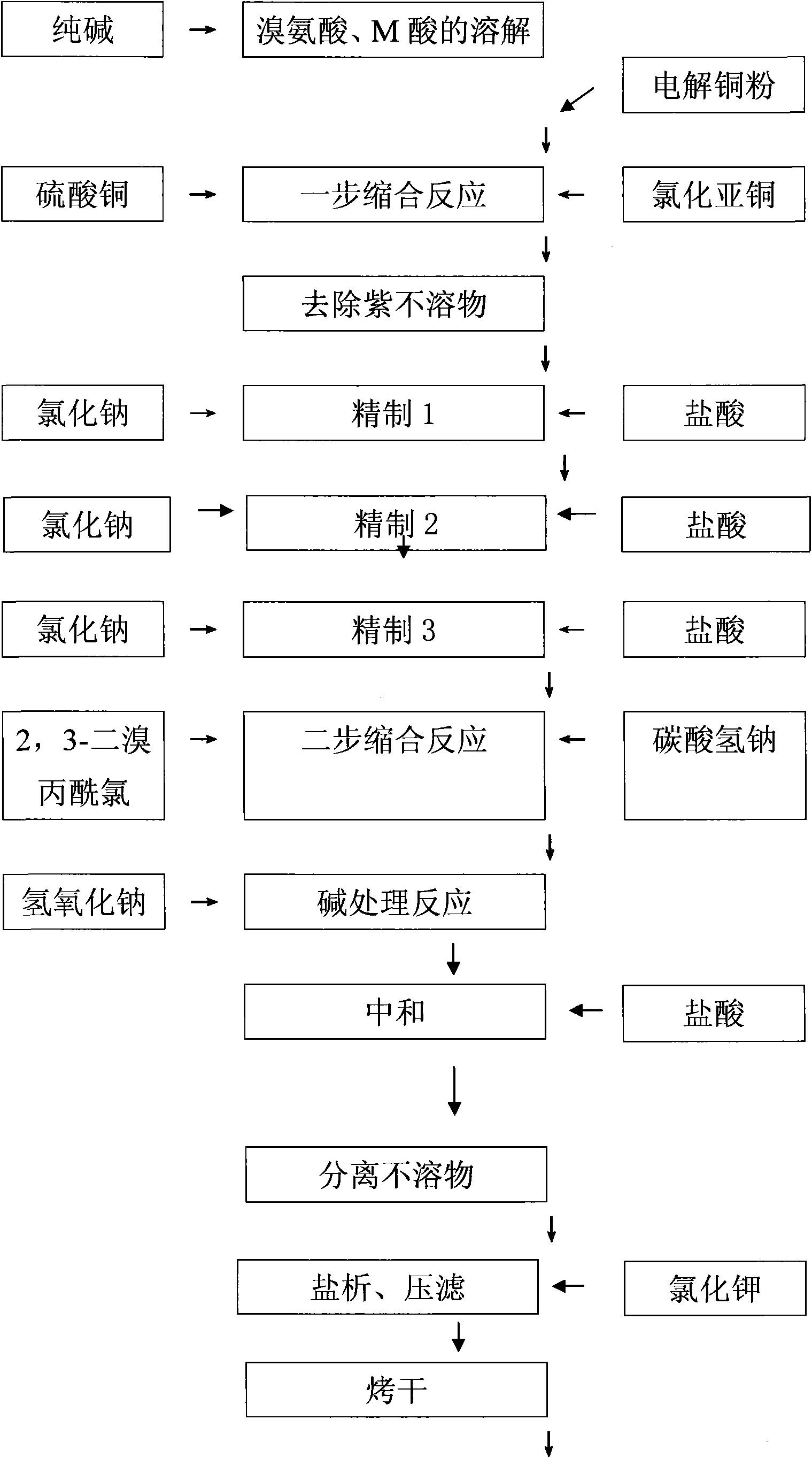

Method used

Image

Examples

Embodiment 1

[0034] (1) Dissolution of bromic acid and M acid: add 1000L of bottom water in the reaction tank, add 100% bromic acid 202KG, 100% M acid 130KG, adjust PH=8-10 with soda ash to dissolve the material under stirring, and control the temperature 50-55°C, c%=20-30 in the solution.

[0035] (2) One-step condensation reaction: respectively add catalyst, 98% cuprous oxide, 98% electrolytic copper powder, 98% copper sulfate each 9KG respectively, and each interval is 10 minutes, temperature control 80~85 ℃, stirring reaction 8 hours, The reaction pH is 8-10, and the TCL plate confirms that it is qualified.

[0036] (3) Removal of purple insoluble matter: use a jacket to cool down, so that the temperature in (2) solution is controlled at 30-45°C, add it to a solid-liquid separator for separation and removal of purple insoluble waste residue, collect the filtrate, confirm that it is qualified with a TCL plate, and set aside . About 5KG of waste residue is used for engineering soil.

...

Embodiment 2

[0047]The dyestuff is prepared according to the process steps described in Example 1, the difference is that in Example 2, 31KG of Yuanming powder is added to obtain 100% dyestuff 325KG.

Embodiment 3

[0049] The dyestuff was prepared according to the process steps described in Example 1, the difference being that 319KG of 100% dyestuff obtained in Example 3 was added with 29KG of Yuanming powder.

[0050] Reactive Brilliant Blue 4R Consumption Quota Table for Preparation of Wool of the Present Invention

[0051] raw material name

Unit consumption, Kg / T

631.3

M acid

406.3

Soda ash

500.0

28.1

Electrolytic copper powder

28.1

[0052] copper sulfate

28.1

2,3-Dibromopropionyl chloride

360.0

[0053] Reactive Brilliant Blue 4R Applied Performance Table for Preparing Wool of the present invention

[0054]

[0055] Reactive Brilliant Blue 4R Consumption Quota Table for Preparation of Wool by Prior Art Process

[0056] raw material name

Unit consumption, Kg / T

673.3

M acid

433.3

So...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com