Method for preparing high-purity iron oxide and trisodium phosphate by ferro-phosphorus alkalization process

A technology of trisodium phosphate and iron oxide, applied in chemical instruments and methods, iron oxide, iron oxide/iron hydroxide and other directions, can solve the problems of low added value of iron oxide red pigment, long roasting time, high energy consumption, etc. Achieve the effect of high added value, high comprehensive utilization rate and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

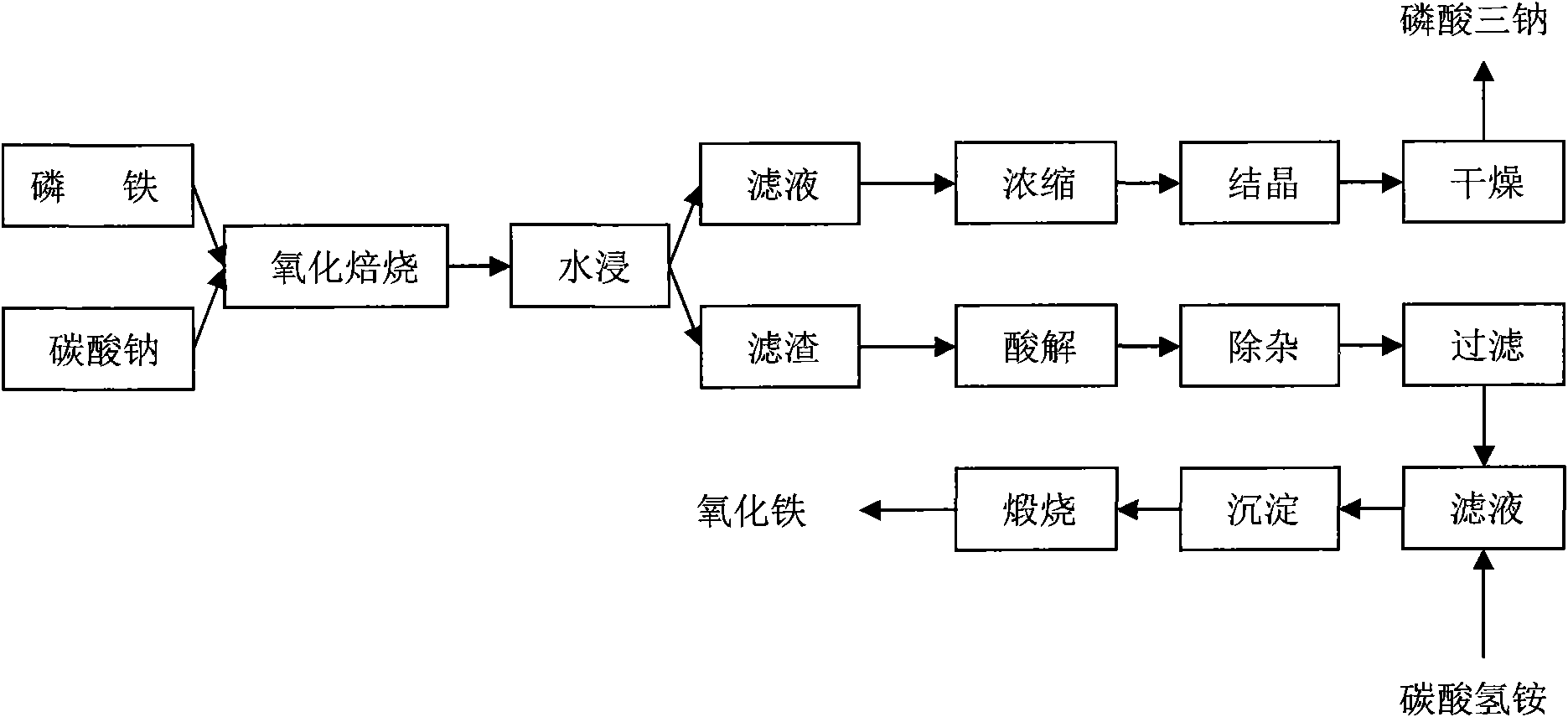

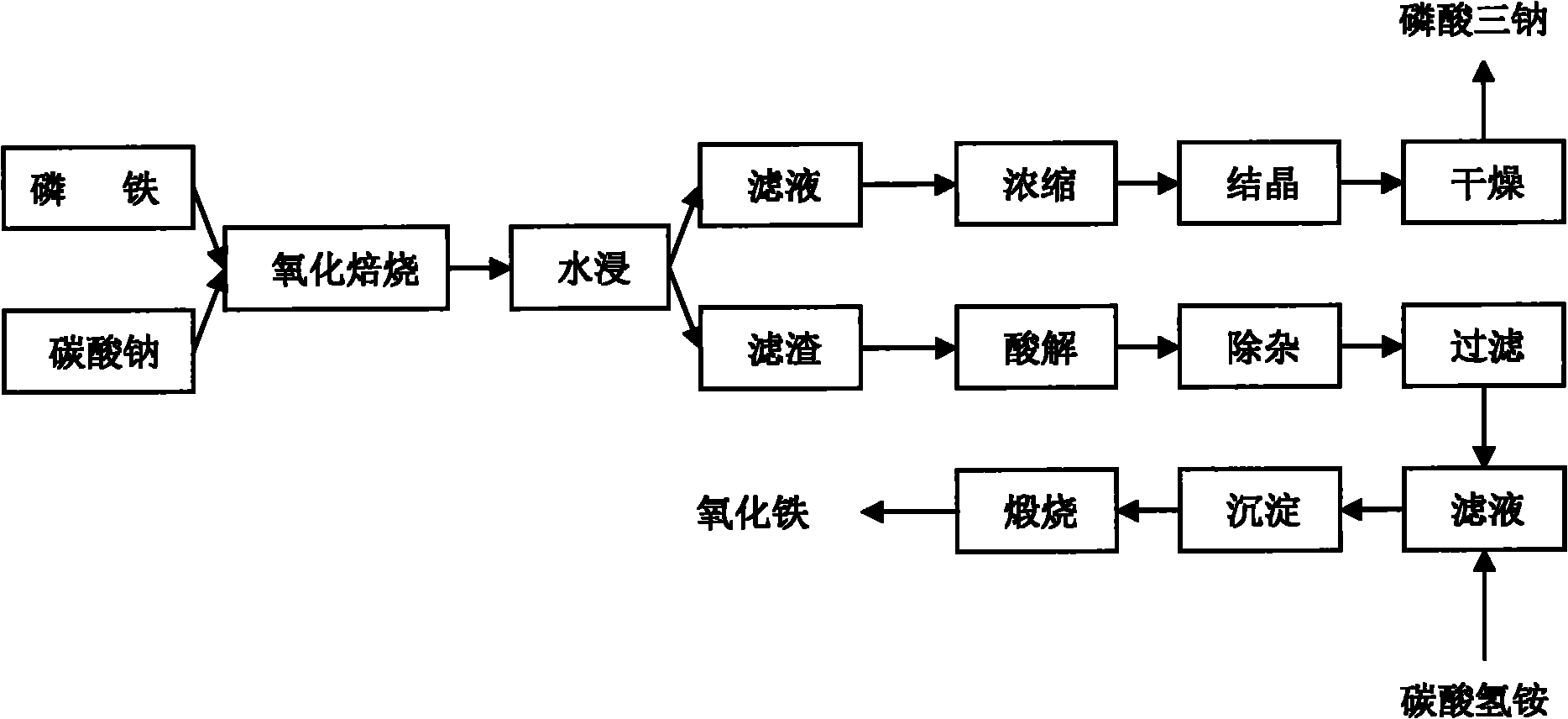

[0038] In the present embodiment, the iron element mass percentage composition is 62.6% in the phosphorus iron, and the phosphorus element content mass percentage composition is 23.8%: prepare high-purity iron oxide and trisodium phosphate technological process according to Figure 1 phosphorus iron alkalization process:

[0039] 1) Roasting

[0040] Ferrophosphorus is pulverized and passed through a 100-mesh sieve, with a particle size of 150 μm accounting for more than 98%, mixed evenly with soda ash at a mass ratio of 1:1.1, aerobically roasted at 700°C for 3 hours, and cooled to room temperature;

[0041] 2) Water immersion and filtration

[0042] After cooling the roasted product obtained in step 1) to room temperature, add 60° C. hot water for immersion according to the mass ratio of the roasted product and water for immersion of 1:6.5, and filter after 4 hours of water immersion to obtain a filtrate and a filter cake;

[0043] 3) Acid hydrolysis

[0044] The filter cak...

Embodiment 2

[0056] In the present embodiment, the iron element mass percentage in the phosphorus iron is 62.6%, and the phosphorus element content mass percentage is 23.8%:

[0057] 1) Roasting

[0058] Ferrophosphorus is pulverized and passed through a 120-mesh sieve, with a particle size of 125 μm reaching more than 98%, mixed evenly with soda ash in a mass ratio of 1:1.2, aerobically roasted at 750°C for 3 hours, and cooled to room temperature;

[0059] 2) Water immersion and filtration

[0060] After cooling the roasted product obtained in step 1) to room temperature, add 70° C. hot water for immersion according to the mass ratio of the roasted product and water for immersion of 1:7, and filter after 4 hours of water immersion to obtain a filtrate and a filter cake;

[0061] 3) Acid hydrolysis

[0062] With the filter cake obtained in step 2) under stirring, slowly add sulfuric acid with a mass concentration of 70% according to the mass ratio of the filter cake and sulfuric acid at ...

Embodiment 3

[0074] In the present embodiment, the iron element mass percentage in the phosphorus iron is 62.6%, and the phosphorus element content mass percentage is 23.8%:

[0075] 1) Roasting

[0076] Ferrophosphorus is pulverized and passed through a 200-mesh sieve, with a particle size of 75 μm reaching more than 98%, mixed evenly with soda ash at a mass ratio of 1:1.2, aerobically roasted at 800°C for 2 hours, and cooled to room temperature;

[0077] 2) Water immersion and filtration

[0078] After cooling the roasted product obtained in step 1) to room temperature, add 75° C. hot water for immersion according to the mass ratio of the roasted product and water for immersion of 1:7.5, and filter after 2 hours of water immersion to obtain a filtrate and a filter cake;

[0079] 3) Acid hydrolysis

[0080] With the filter cake obtained in step 2) under stirring, slowly add sulfuric acid with a mass concentration of 85% according to the mass ratio of the filter cake to sulfuric acid of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com