Method for producing high-purity triazine-based charring agent

A production method and technology of triazines, which are applied in the field of production of high-purity triazines char-forming agents, can solve problems such as low yield, poor product stability, and poor polymer compatibility, so as to reduce loss rate and improve purity , the effect of easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

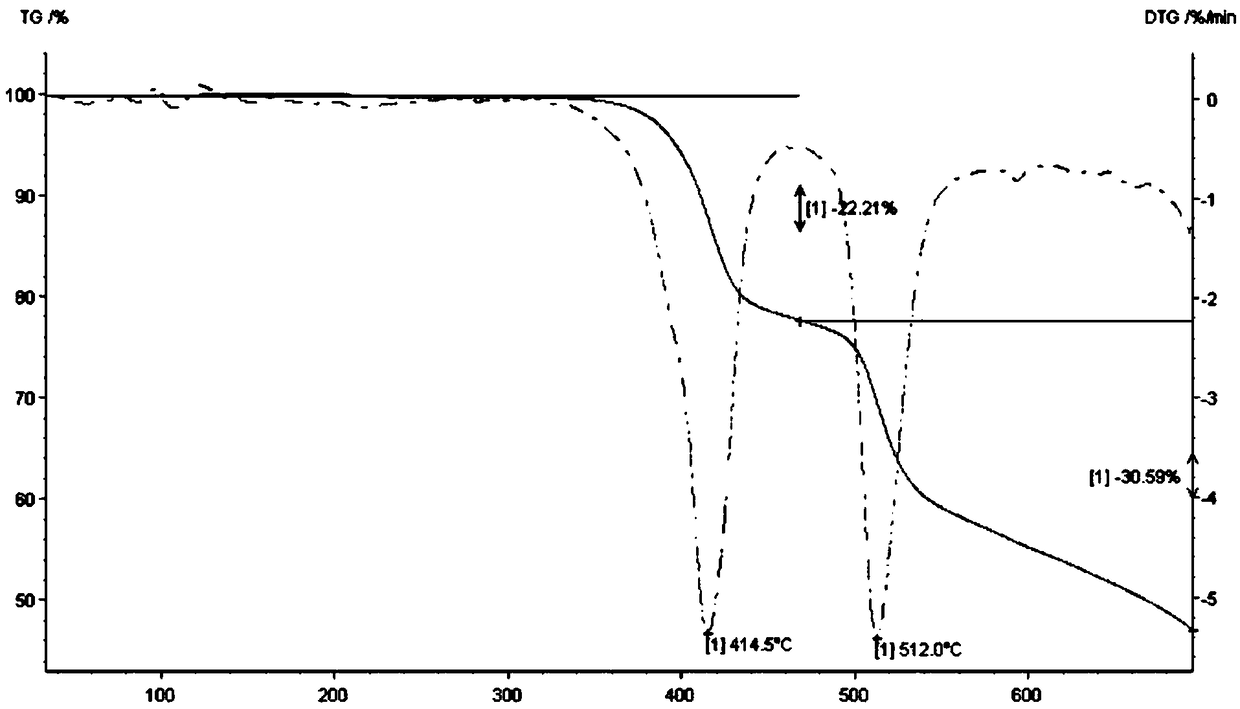

Image

Examples

Embodiment 1

[0038] In a 500L reactor with a stirring and condensing device, when the temperature of the pure water in the reactor is lower than 10°C, suspend and disperse 25.00kg of cyanuric chloride in 250L of pure water, slowly add 184L of 25% ammonia solution, and control The reaction temperature is within 15°C, after the addition is completed, the temperature is kept at 58-60°C, and the reaction time is 2 hours; after the reaction is completed, the above solution is pressed into a filter press for press filtration to obtain a semi-finished product A with a solid content of 31.25%; at the same time The press filtrate can be recycled; then, add 62.41kg of the above-mentioned semi-finished product and 160L of pure water into a 500L reactor with a stirring and reflux device, after fully dispersing, control the temperature at 25-30°C, add 5.80kg of piperazine, After the addition is completed, the reaction temperature is controlled at 95-98°C, and then 18.83kg of 30% sodium hydroxide solutio...

Embodiment 2

[0040]In a 1000L reactor with a stirring and condensing device, when the temperature of the pure water in the reactor is lower than 10°C, suspend and disperse 50.00kg of cyanuric chloride in 450L of pure water, slowly add 430L of 25% ammonia solution, and control The reaction temperature is within 20°C. After the addition is complete, keep the temperature at 55°C and the reaction time is 3 hours; after the reaction, press the above solution into a filter press for press filtration to obtain a semi-finished product A with a solid content of 32.15%; It can be recycled; then, add 118.88kg of the above-mentioned semi-finished product and 350L of pure water into a 1000L reactor with a stirring and reflux device. After fully dispersing, control the temperature at 28-35°C, add 11.72kg of piperazine, and complete the addition , control the reaction temperature at 90-95°C, then add 37.66kg of 30% sodium hydroxide solution, the pH of the whole process is controlled at 8-9, after adding, ...

Embodiment 3

[0042] In a 3000L reactor with a stirring and condensing device, when the temperature of the pure water in the reactor is lower than 10°C, suspend and disperse 150.00kg of cyanuric chloride in 1500L of pure water, slowly add 1200L of 25% ammonia solution, and control The reaction temperature is within 14°C. After the addition is complete, the temperature is maintained at 57-60°C and the reaction time is 4 hours; after the reaction is completed, the above solution is pressed into a filter press for press filtration to obtain a semi-finished product A with a solid content of 31.75%; at the same time The press filtrate can be recycled; then, add 368.58kg of the above-mentioned semi-finished product and 1000L of pure water into a 3000L reactor with a stirring and reflux device, after fully dispersing, control the temperature at 28-35°C, add 34.71kg of piperazine, After adding, control the reaction temperature at 95-100°C, then add 112.98kg of 30% sodium hydroxide solution, control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com