Preparation method of nano lead/carbon composite material and application of nano lead/carbon composite material

A technology of carbon composite materials and carbon materials, which is applied in the direction of lead-acid batteries, electrical components, battery electrodes, etc., can solve the problems of increasing battery self-discharge rate, low content requirements, and high impurity content, so as to improve cycle life and inhibit Hydrogen evolution reaction, the effect of small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

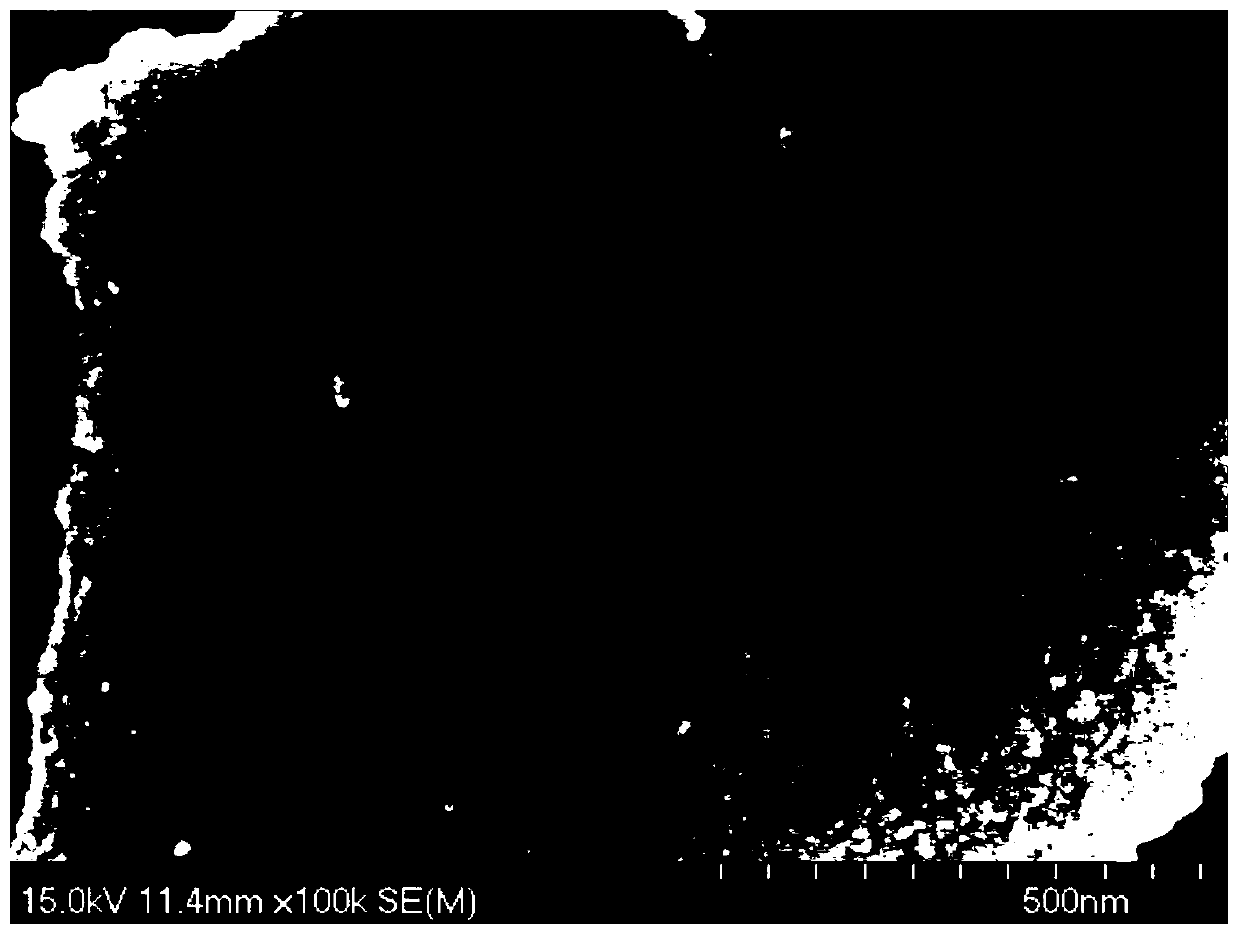

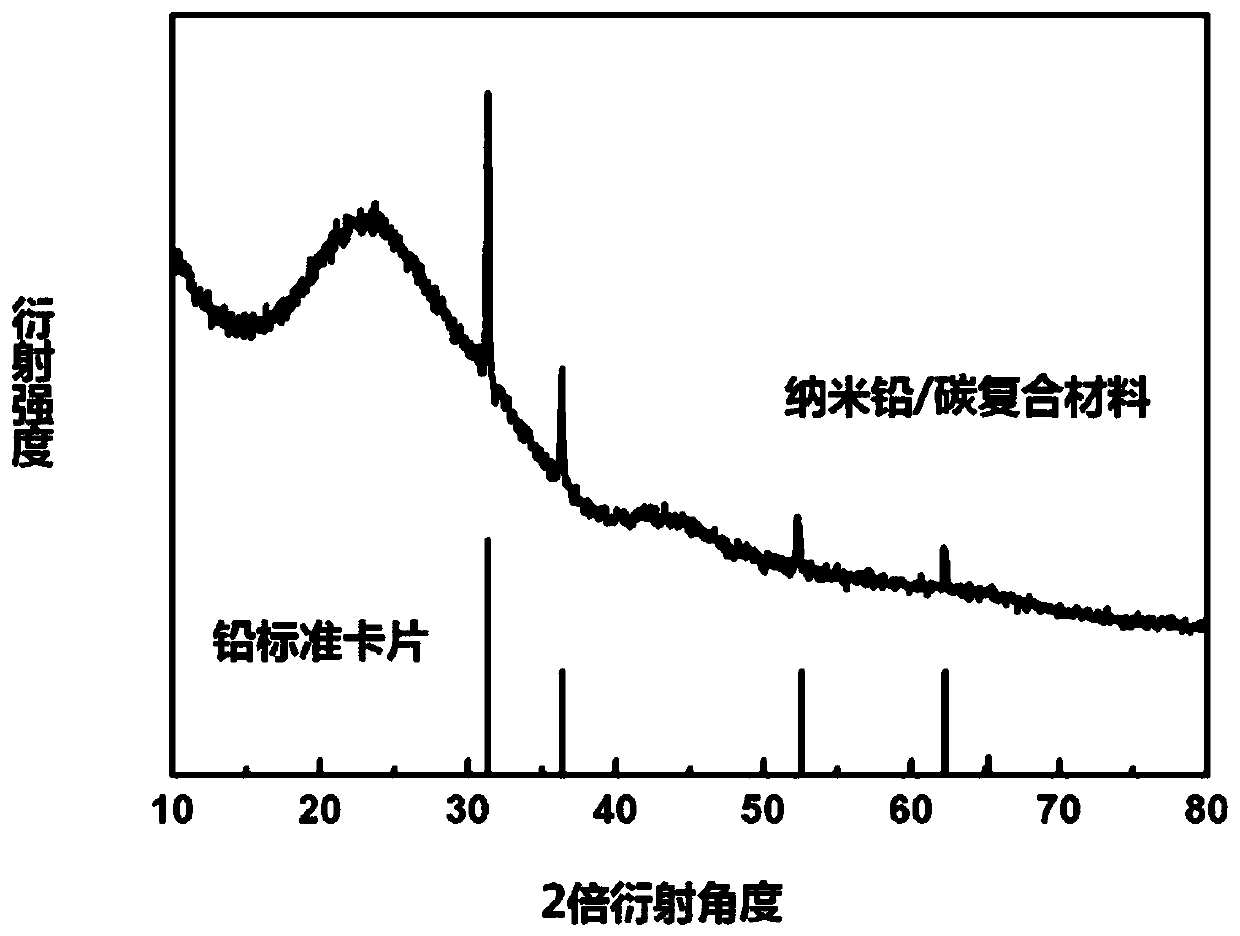

Examples

Embodiment 1

[0036] (1) Prepare solution 1: add 10 ml of deionized water to a 50 ml beaker, then add 10 ml of 30% hydrogen peroxide, stir with a glass rod, and mix well.

[0037] (2) Prepare solution 2: add 1 g of coconut shell carbon (hydrogen evolution overpotential is 1.22V, specific capacitance is 160F / g) into solution 1, and then stir under magnetic force for half an hour.

[0038] (3) Prepare solution 3: add 50 ml of deionized water to a 250 ml beaker, then add 1.655 g of lead nitrate, and stir magnetically for half an hour.

[0039] (4) Prepare solution 4: add solution 2 to solution 3, and stir magnetically for half an hour.

[0040] (5) Precursor preparation: Add 0.5g CTAB to solution 4, stir magnetically for one hour, vacuum filter, put the solid in a vacuum drying oven, set the temperature at 80°C, and dry for 12 hours to obtain the precursor.

[0041] (6) Product preparation: Grind the precursor into powder and put it into a tube furnace. The setting procedure is as follows: th...

Embodiment 2

[0045] (1) Solution 1: Add 20 ml of deionized water into a 50 ml beaker, then add 10 ml of 30% hydrogen peroxide, stir with a glass rod, and mix well.

[0046] (2) Solution 2: Add 0.1 g of rice husk charcoal (hydrogen evolution overpotential is 1.2V, specific capacitance is 175F / g) into solution 1, and then stirred under magnetic force for one hour.

[0047] (3) Solution 3: 50 ml of deionized water was added to a 250 ml beaker, and then 1 g of lead chloride was added, and magnetically stirred for one hour.

[0048] (4) Solution 4: Add solution 2 into solution 3, and stir magnetically for half an hour.

[0049] (5) Precursor preparation: Add 0.1 g of PVP to solution 4, stir magnetically for one hour, vacuum filter, put the solid in a vacuum drying oven, set the temperature at 80°C, and dry for 12 hours.

[0050] (6) Product preparation: Grind the precursor into powder and put it into a tube furnace. The setting procedure is as follows: the initial temperature is 25°C, the heatin...

Embodiment 3

[0056] (1) Solution 1: Add 80 ml of deionized water to a 250 ml beaker, then add 40 ml of 30% hydrogen peroxide and 40 ml of nitric acid, stir with a glass rod, and mix well.

[0057] (2) Solution 2: Add 1.0 g of graphene (hydrogen evolution overpotential is 1.10V, specific capacitance is 202F / g.) into solution 1, and then stirred under magnetic force for one hour.

[0058] (3) Solution 3: 50 ml of deionized water was added to a 250 ml beaker, and then 5 g of lead acetate was added, and magnetically stirred for one hour.

[0059] (4) Solution 4: Add solution 2 into solution 3, and stir magnetically for half an hour.

[0060] (5) Precursor preparation: Add 1 g of CTAB to solution 4, stir magnetically for one hour, vacuum filter, put the solid in a vacuum drying oven, set the temperature at 80°C, and dry for 12 hours.

[0061] (6) Product preparation: Grind the precursor into powder and put it into a tube furnace. The setting procedure is as follows: the initial temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com