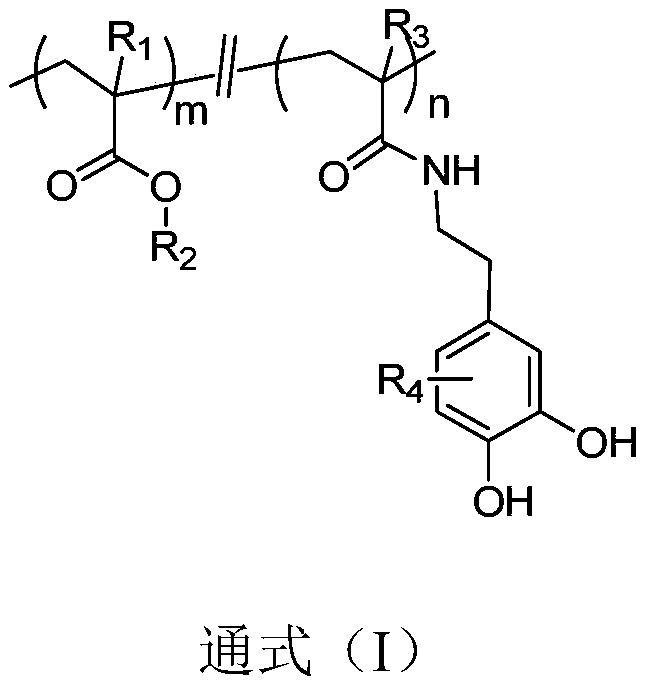

Surface coating polymer, and preparation method and application thereof

A surface coating and polymer technology, applied in the application of anti-bacterial adhesion functional materials, in the field of surface coating polymers, it can solve the problems of easy falling off and low safety of the coating, and achieve excellent antibacterial effect and not easy to fall off. , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

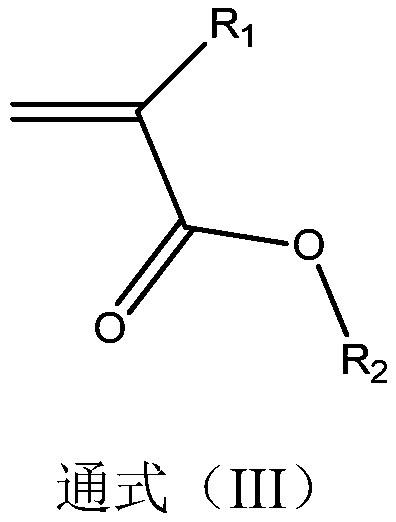

[0086] The preparation of embodiment 1 pentafluorophenol acrylate

[0087] M1 # monomer

[0088] Synthesis: Add pentafluorophenol, potassium carbonate and refined THF solvent into a round bottom flask; dissolve acryloyl chloride in refined THF, stir evenly at room temperature and then transfer to a constant pressure dropping funnel; among them, pentafluorophenol, The molar ratio of potassium carbonate and acryloyl chloride is 1:8:8. Put the round-bottomed flask into a low temperature and constant temperature stirring reaction bath at -10°C, add the acryloyl chloride solution dropwise into the round-bottomed flask, and react at constant temperature for 6 hours. After the reaction was stopped, the inorganic solids were removed by centrifugation, and the solvent THF was removed by rotary evaporation; dichloromethane and water were added to the mixture obtained by rotary evaporation for extraction, and the extracted lower layer liquid was rotary evaporated again to obtain the ...

Embodiment 2

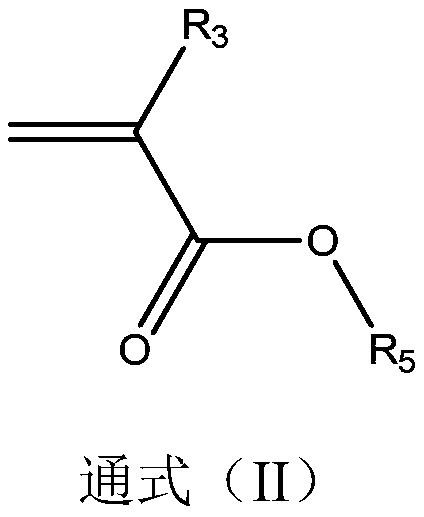

[0096] Preparation of embodiment 2 surface coating polymer

[0097] Typically, the RAFT random copolymerization is carried out by using the pentafluorophenol acrylate prepared in Example 1 as the first monomer and 2-methacryloyloxyethyl phosphorylcholine as the second monomer. When the zwitterion of the second monomer is replaced by a sulfobetaine group, a carboxybetaine group, or a substituent group thereof, the polymerization process is roughly the same as that in this embodiment.

[0098] The first monomer pentafluorophenol acrylate, the initiator azobisisobutyronitrile (AIBN), the chain transfer agent 2-cyano-2-propylbenzodisulfide, the second monomer 2-methacryloyloxy Ethyl phosphorylcholine (MPC) was dissolved in purified methanol at a molar ratio of 26.67:0.2:1:40, added into a Schlenk bottle, and reacted in an oil bath at 70°C for 24 hours after three freeze-thaw cycles. After the reaction, the crude product was precipitated with acetone and separated, and purified by...

Embodiment 3

[0101] Antibacterial adhesion performance of embodiment 3 surface coating polymer

[0102] Substrate surface is immersed in the solution of the surface coating polymer that prepares in embodiment 2, obtains antibacterial adhesion coating, and the antibacterial adhesion property of coating has been tested, specifically as follows:

[0103] Prepare two planar PVC substrates of 5cm × 3cm, one PVC substrate surface is coated with the surface coating polymer prepared in embodiment 2, and is recorded as PVC-TC spline; the other is compared as a blank sample, Denoted as PVC-ctr spline.

[0104] The anti-bacterial adhesion performance test is carried out according to the following steps:

[0105] Place the PVC sample strip in the E. coli bacterial liquid, incubate it in a constant temperature shaking box at 37°C for 48 hours, take out the sample strip, and wash it with sterile PBS (phosphate buffer saline, pH=7.2-7.4) for 9 times to remove pseudo-adherent bacteria , then put the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com