Recycle utilization process of magnesium alloy compression casting waste material

A magnesium alloy and waste technology is applied in the field of recycling process of magnesium alloy die-casting waste to achieve the effects of not harsh conditions, resource saving and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

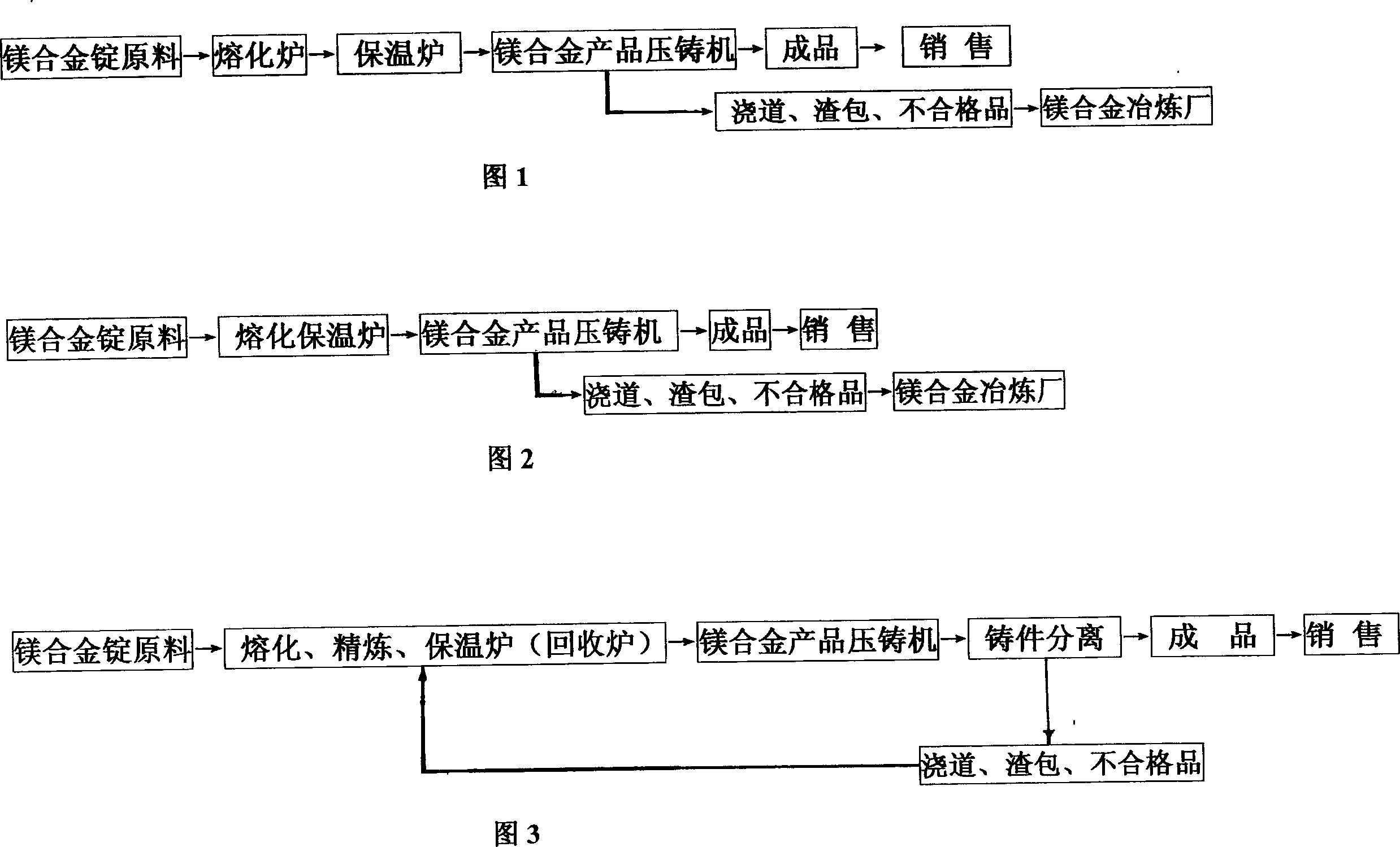

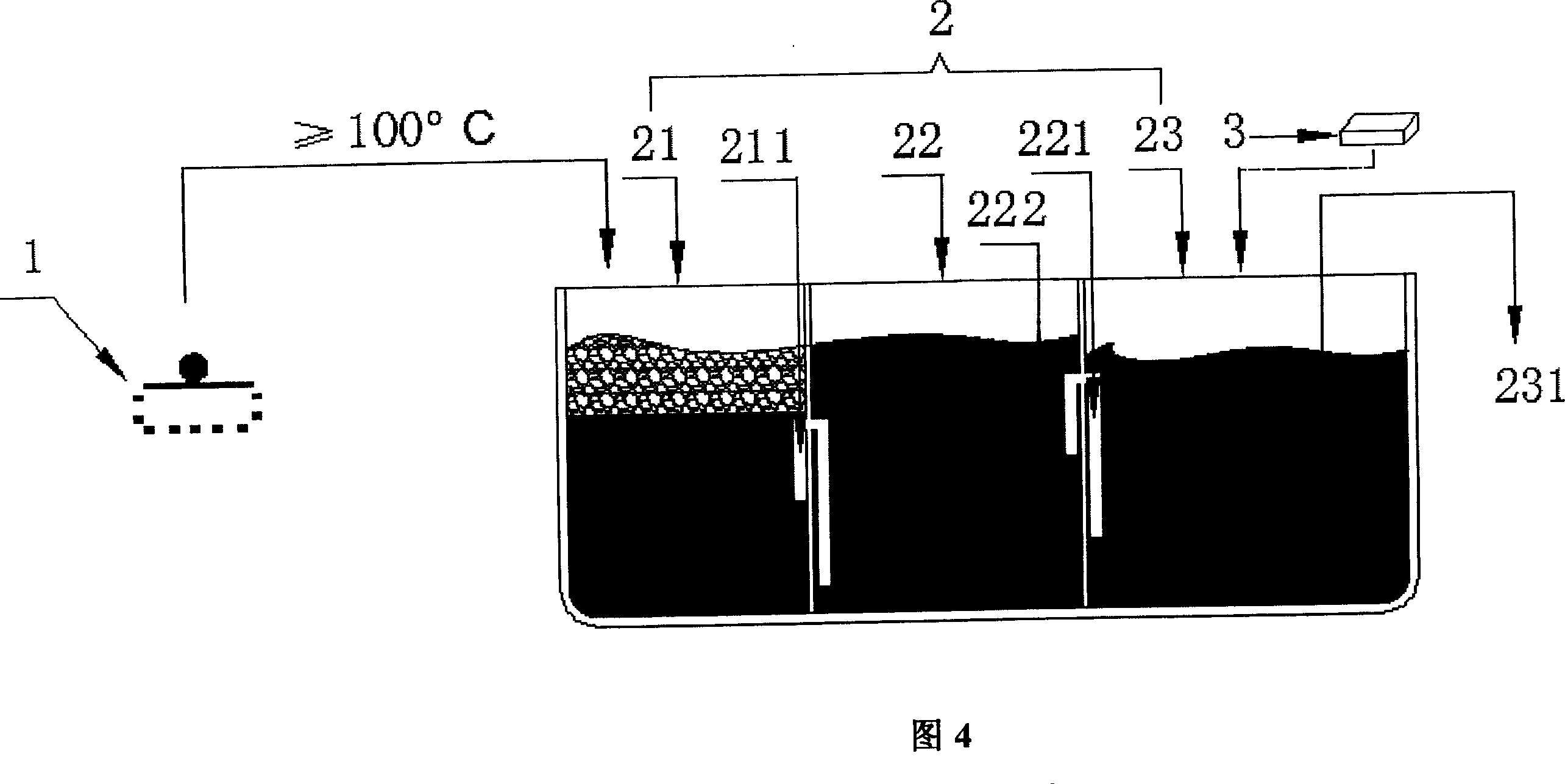

[0025] Please combine Figure 3 and Figure 4.

[0026] A) Utilize the method recommended by the present invention to separate the castings obtained by the die-casting of the magnesium alloy product die-casting machine, specifically to separate the products that have just been die-casted at a temperature above 300 ° C from the sprue and the slag bag. The tools used are hydraulic presses and trimming dies. The hydraulic presses are YH series hydraulic presses produced by Hefei Forging Machine Tool Factory in Hefei City, Anhui Province, China, and the temperature of the separated sprue and slag bag is guaranteed to be above 100°C, so as to obtain magnesium alloy. Scrap (shown in Figure 4), it goes without saying that the magnesium alloy scrap 1 obtained also includes the unqualified casting products that have just been die-casted;

[0027] B) Magnesium alloy scrap 1 is continuously transported to the melting chamber 21 of the recovery furnace 2, which is the melting and refining f...

Embodiment 2

[0030] Only change the melting temperature described in step B) to 690°C, the refining temperature to 716°C, the addition of refining agent 222 to 2.8%, and the holding temperature described in step C) to 676°C, and the rest Same as the description of embodiment 1.

Embodiment 3

[0032] Only change the melting temperature described in step B) to 715°C, the refining temperature to 705°C, the amount of refining agent 222 added to 4.6%, and the holding temperature described in step C) to 685°C, and the rest Same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com