Method for auxiliary preparation of different-shape nano-cerium oxide with microwave

A nano-cerium oxide, microwave-assisted technology, applied in chemical instruments and methods, microwave heating, inorganic chemistry and other directions, can solve the problems of high preparation cost, complex process, poor controllability of nanomaterial particle size and morphology, etc. The effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

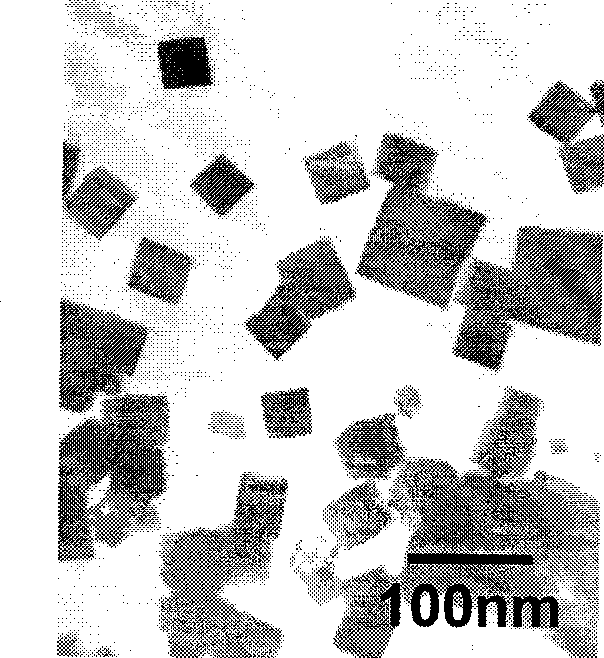

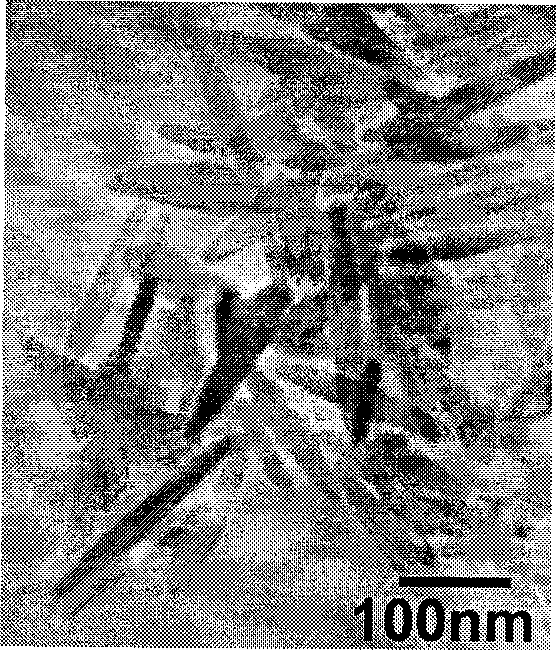

Embodiment 1

[0029] According to the preparation process, Ce(NO 3 ) 3 Prepare a concentration of 0.01mol / l aqueous solution, add 0.01mol / l Ce(NO 3 ) 3 Add 100ml of aqueous solution, 100ml of ethylene glycol, 8ml of oleic acid, and 1.2ml of tert-butylammonium into a high-temperature reaction kettle with a sealing device and a liner coated with tetrafluoroethylene, without any stirring. After sealing the reaction kettle, heat it in a 2.5GHz household microwave oven for 10 minutes. The heating power of the microwave oven is 900w. After the reaction was finished, the resulting mixture was cooled to room temperature, and acetone with a volume of 700 ml was added to the mixture to wash away ethylene glycol and oleic acid, then ultrasonically treated for 5 min, and the mixture was centrifuged at a rate of 10,000 rpm 5min. The separated solid was washed with absolute ethanol, ultrasonically treated, centrifuged, and repeated 5 times to obtain a solid powder that was dried in a vacuum oven for...

Embodiment 2

[0031] According to the preparation process, Ce(NO 3 ) 3 Prepare a concentration of 0.05mol / l aqueous solution, add 0.05mol / l Ce(NO 3 ) 3 Add 100ml of aqueous solution, 120ml of ethylene glycol, 10ml of oleic acid, and 0.8ml of tert-butylammonium into a high-temperature reaction kettle with a sealing device and a liner coated with tetrafluoroethylene, without any stirring. After sealing the reaction kettle, heat it in a 2.5GHz household microwave oven for 10 minutes. The heating power of the microwave oven is 1000w. After the reaction is finished, the resulting mixture is cooled to room temperature, and acetone with a volume of 1000 ml of the mixture volume is added to the mixture to wash away ethylene glycol and oleic acid, then ultrasonically treated for 5 min, and the mixture is centrifuged at a rate of 10,000 rpm 7min. The separated solid was washed with absolute ethanol, ultrasonically treated and centrifuged, and repeated 5 times to obtain a solid powder that was dr...

Embodiment 3

[0033] According to the preparation process, Ce(NO 3 ) 3 Prepare a concentration of 0.1mol / l aqueous solution, add 0.1mol / lCe(NO 3 ) 3 Add 100ml of aqueous solution, 80ml of ethylene glycol, 8ml of oleic acid, and 0.6ml of tert-butylammonium into a high-temperature reaction kettle with a sealing device and a liner coated with a layer of tetrafluoroethylene, without any stirring. After sealing the reaction kettle, heat it in a 2.5GHz household microwave oven for 10 minutes. The heating power of the microwave oven is 600w. After the reaction is finished, the resulting mixture is cooled to room temperature, and acetone with a volume of 1000 ml of the mixture volume is added to the mixture to wash away ethylene glycol and oleic acid, then ultrasonically treated for 5 min, and the mixture is centrifuged at a rate of 10,000 rpm 7min. The separated solid was washed with absolute ethanol, ultrasonically treated and centrifuged, and repeated six times to obtain a solid powder that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com