Method for preparing silver nano-wire in large batch

A silver nanowire, large-scale technology, applied in the field of large-scale preparation of silver nanowires, can solve the problems of increasing the complexity of the reaction process, and achieve the effects of high practical value, saving reaction time, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

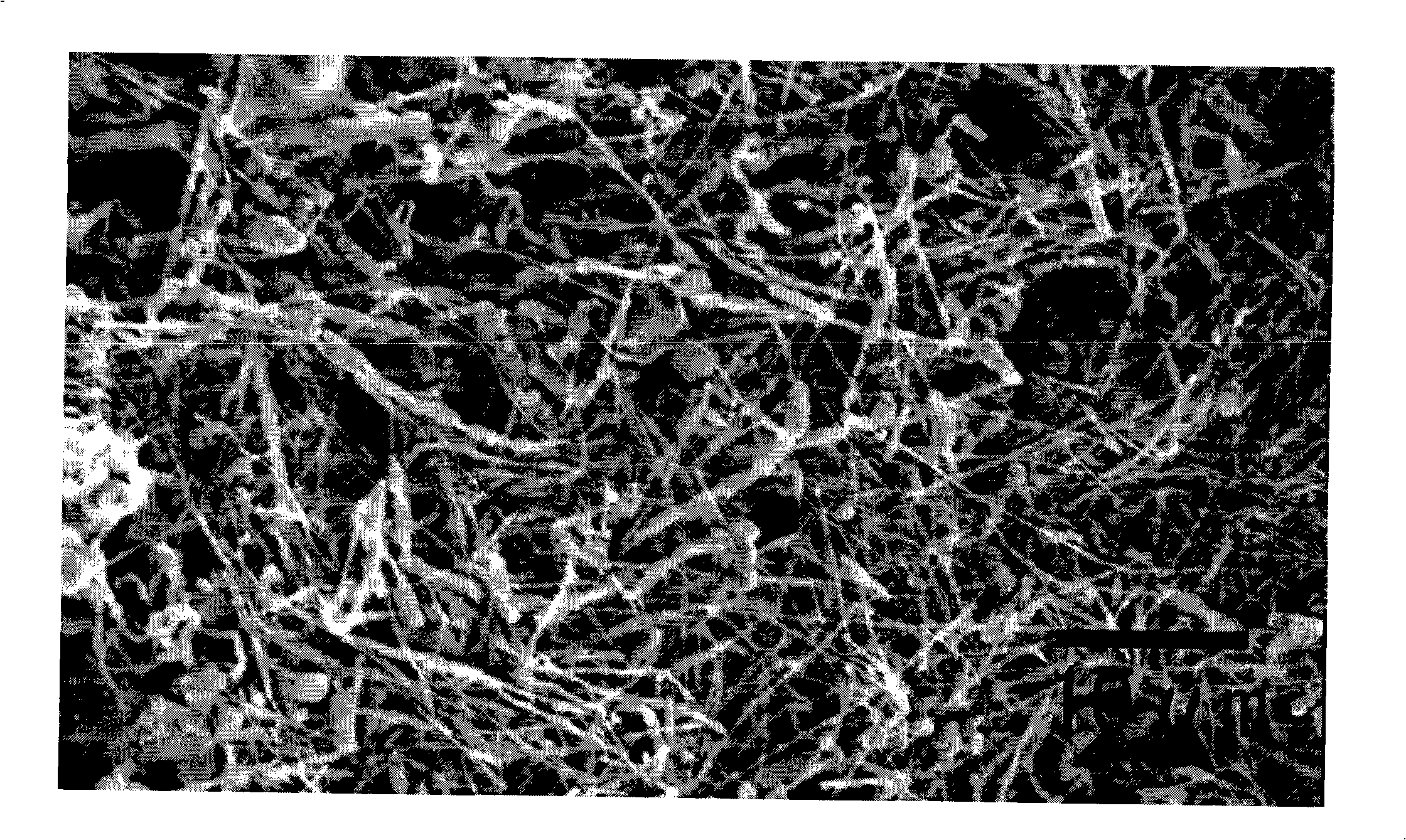

[0026] According to the preparation process, 50ml 0.01mol / l AgNO 3 The ethylene glycol solution of 0.02mol / l PVP and the ethylene glycol solution of 50ml 0.02mol / l PVP are dropped into 50ml ethylene glycol at a rate of 1 drop / second and mixed, and then the mixed solution is transferred to a 2.5GHz household microwave oven for heating, and the microwave power is adjusted 100w, microwave treatment 5min. After the reaction was completed, the resulting mixture was cooled to room temperature, and 400 ml of acetone was added to the mixture to wash away ethylene glycol and excess PVP, then ultrasonically treated for 5 minutes, and the mixture was centrifuged at 10,000 rpm for 5 minutes. The separated solid was washed with deionized water, ultrasonically treated and centrifuged, and repeated 5 times to obtain a solid powder that was dried in a vacuum oven for 6 hours to obtain solid silver nanowires. For the field emission scanning electron microscope (FESEM) sample, the powder sampl...

Embodiment 2

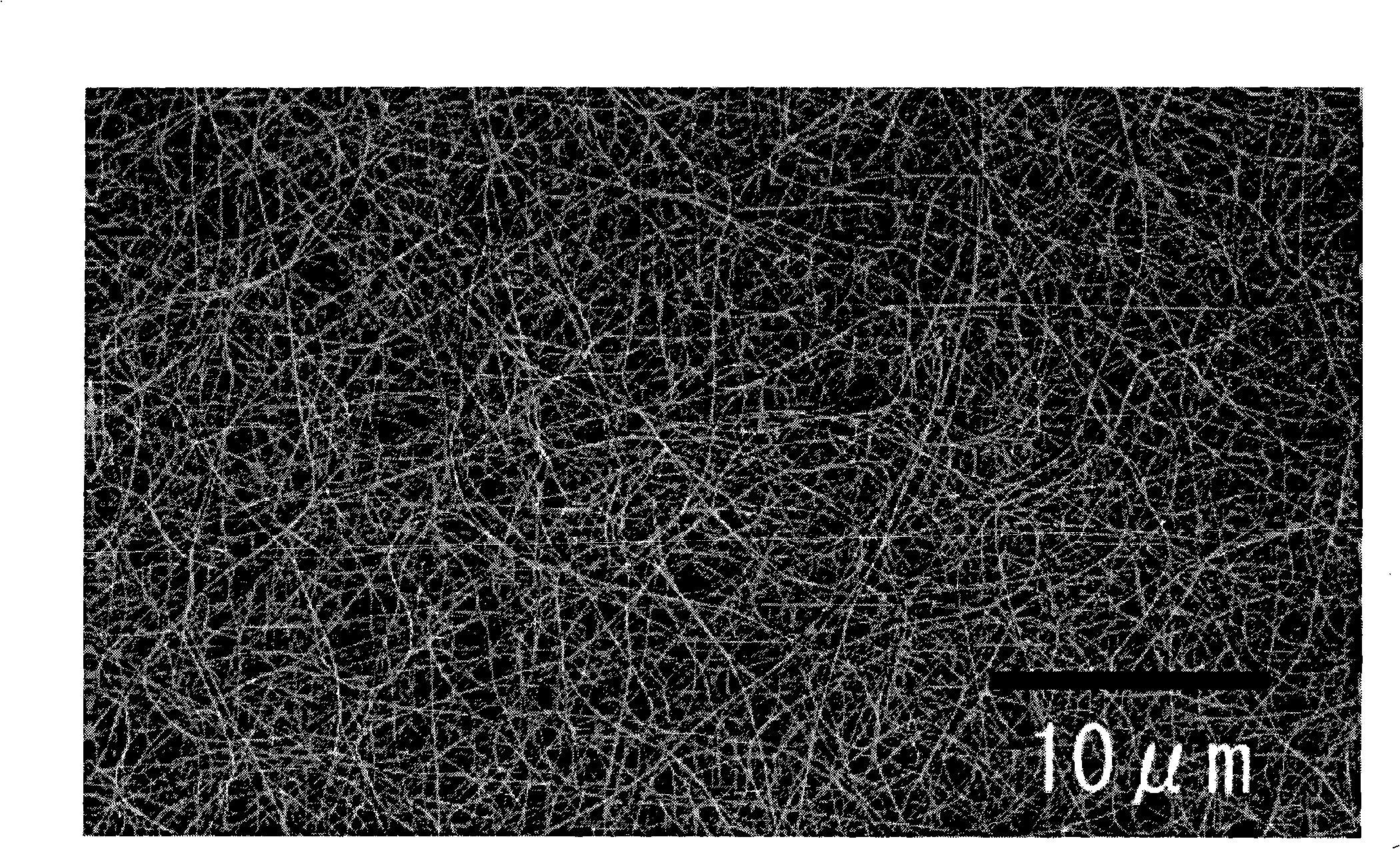

[0028] According to the preparation process, 50ml 0.03mol / l AgNO 3 The ethylene glycol solution of 0.06mol / l PVP and the ethylene glycol solution of 50ml 0.06mol / l PVP are dropped into 100ml ethylene glycol at a rate of 3 drops / second and mixed, and then the mixed solution is transferred to a 2.5GHz household microwave oven for heating, and the microwave power is adjusted 300w, microwave treatment 8min. After the reaction was completed, the resulting mixture was cooled to room temperature, and 700 ml of acetone was added to the mixture to wash away ethylene glycol and excess PVP. Then, it was sonicated for 8 minutes, and the mixture was centrifuged at 10,000 rpm for 8 minutes. The separated solid was washed with deionized water, ultrasonically treated and centrifuged, and repeated six times to obtain a solid powder that was dried in a vacuum oven for 8 hours to obtain solid silver nanowires. For the field emission scanning electron microscope (FESEM) sample, the powder sample...

Embodiment 3

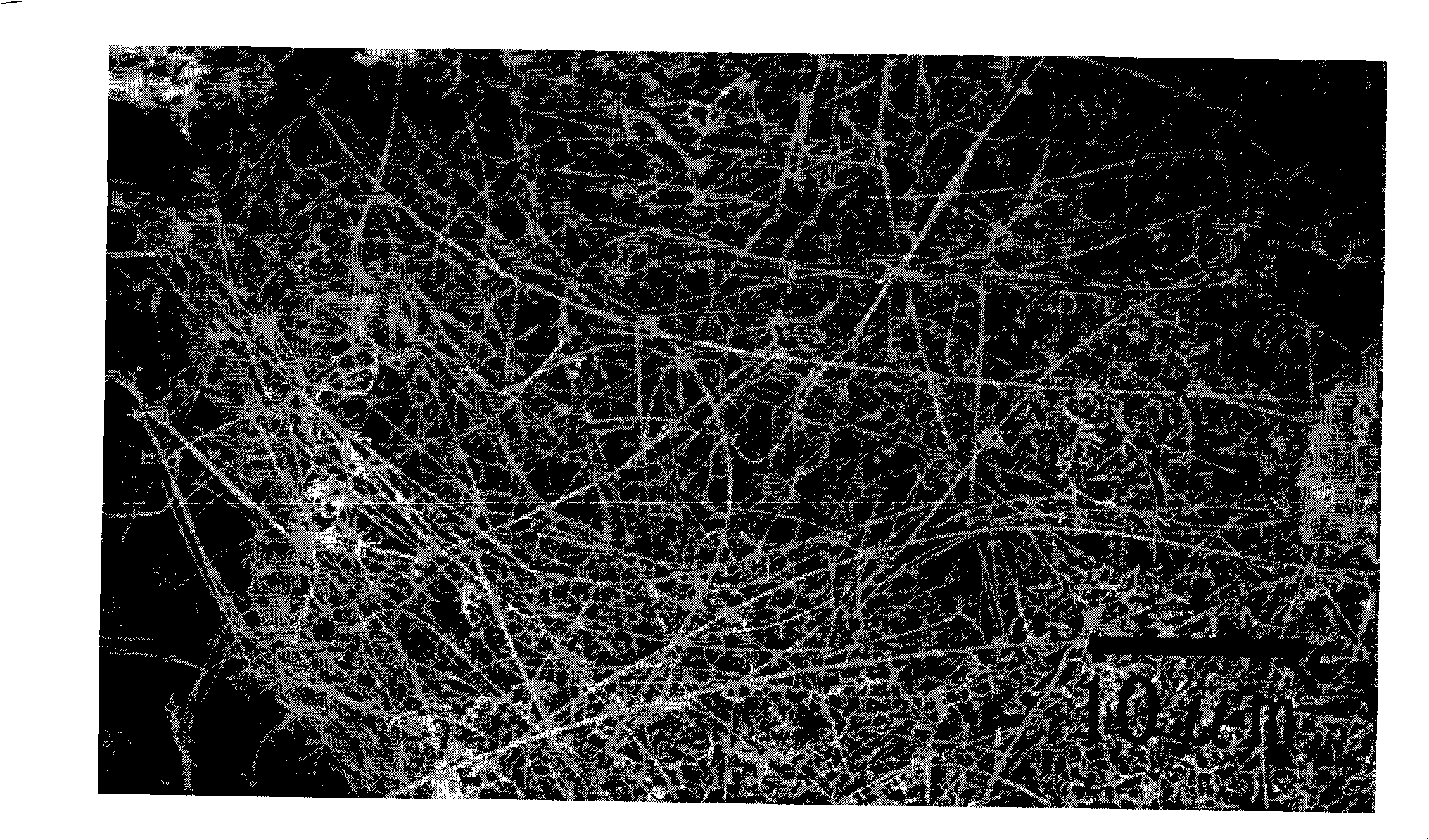

[0030] According to the preparation process, 50ml 0.05mol / l AgNO 3 The ethylene glycol solution of 0.1mol / l PVP and the ethylene glycol solution of 50ml 0.1mol / l PVP are dropped into 250ml ethylene glycol at a rate of 5 drops / second and mixed, and then the mixed solution is transferred to a 2.5GHz household microwave oven for heating, and the microwave power is adjusted For 1000w, microwave treatment for 10min. After the reaction was finished, the resulting mixture was cooled to room temperature, and 1000 ml of acetone was added to the mixture to wash away ethylene glycol and excess PVP, then ultrasonically treated for 10 minutes, and the mixture was centrifuged at 10,000 rpm for 10 minutes. The separated solid was then washed with deionized water, ultrasonically treated and centrifuged, and repeated six times to obtain a solid powder that was dried in a vacuum oven for 10 hours to obtain solid silver nanowires. For the field emission scanning electron microscope (FESEM) samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com