A kind of micron-scale elemental copper catalyst and its preparation method and application

A single copper, micron-scale technology, applied in chemical instruments and methods, light water/sewage treatment, water pollutants, etc., can solve the problems of high price, poor safety, iron sludge pollution, etc., and achieve simple operation, low cost, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Preparation of Catalyst Cu Microparticles:

[0018] (1) Preparation of precursors

[0019] Weigh 0.156g (1mmol) of 4,4'-bipyridine and dissolve it in 10mL of methanol, slowly add this solution to the solution containing 0.232g (1mmol) of Cu(NO 3 ) 2 ·3H 2 In the 15mL aqueous solution of O, a blue precipitate is formed. Add 10mL aqueous solution containing 0.210g (1mmol) 1,3,5-tribenzenetriacid and 0.204g (2mmol) triethylamine to the above reaction solution, and stir 40min, suction filtration, to obtain the sky blue precursor complex;

[0020] (2) Preparation of Cu microparticles

[0021] Take 0.2g of the above-mentioned sky blue precursor complex in N 2 Calcining at 400°C for 2 hours under the same conditions can prepare the micron-sized elemental copper catalyst.

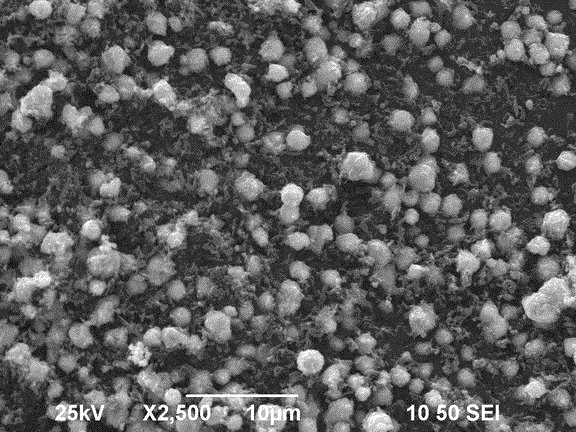

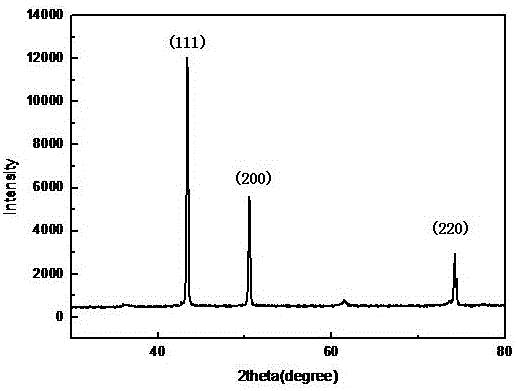

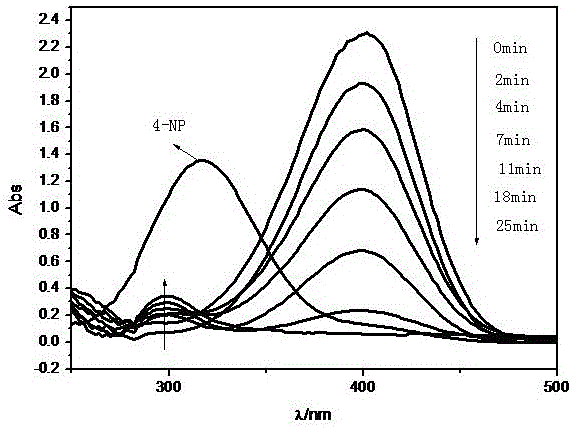

[0022] figure 1 The scanning electron microscope image of the micron-sized elemental copper catalyst prepared for this example shows a small particle structure with an average particle size of 1.82 μm...

Embodiment 2

[0024] Preparation of Catalyst Cu Microparticles:

[0025] (1) Preparation of precursors

[0026] Weigh 0.156g (1mmol) 4,4'-bipyridine and dissolve it in 10mL of methanol, slowly add this solution to the dissolved 0.464g (2mmol) Cu(NO 3 ) 2 ·3H 2 In the 15mL aqueous solution of O, a blue precipitate was formed. Add 10mL aqueous solution dissolved with 0.210g (1mmol) 1,3,5-benzenetrilic acid and 0.204g (2mmol) triethylamine to the above reaction solution, and stir for 60min. , suction filtration, to obtain sky blue precursor complex;

[0027] (2) Preparation of Cu microparticles

[0028] Take 0.2g of the above-mentioned sky blue precursor complex in N 2 Calcining at 600°C for 1.5 hours under the same conditions can prepare the micron-sized elemental copper catalyst.

Embodiment 3

[0030] Preparation of Catalyst Cu Microparticles:

[0031] (1) Preparation of precursors

[0032] Weigh 0.156g (1mmol) 4,4'-bipyridine and dissolve it in 10mL of methanol, and slowly add this solution to the dissolved 0.928g (4mmol) Cu(NO 3 ) 2 ·3H 2 In the 15mL aqueous solution of O, a blue precipitate was formed, and 10mL aqueous solution dissolved with 0.210g (1mmol) of 1,3,5-benzenetrilic acid and 0.204g (2mmol) of triethylamine was added to the above reaction solution, and stirred for 2h , suction filtration, to obtain sky blue precursor complex;

[0033] (2) Preparation of Cu microparticles

[0034] Take 0.2g of the above-mentioned sky blue precursor complex in N 2 Calcining at 800°C for 1 hour under the same conditions can prepare the micron-sized elemental copper catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com