Annular nano germanium dioxide/polyion liquid composite material and preparation method and application thereof

A technology of polyionic liquid and germanium dioxide, which is applied in the direction of secondary batteries, electrochemical generators, electrical components, etc., can solve problems such as unsatisfactory cycle performance, capacity fading, and drastic volume changes of germanium-based materials, and achieve excellent dissolution performance, high charge and discharge capacity, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the annular nano-germanium dioxide / polyionic liquid composite material of the present embodiment, the steps are as follows:

[0029] (1) First, 1.5 g of bisvinylimidazolium bromide ionic liquid and 1.5 g of germanium tetrachloride were dissolved in 15 mL of absolute ethanol solution, and the above solution was fully stirred for 2 h;

[0030] (2) Add 375 mg of azobisisobutyronitrile to the above-mentioned mixed solution, heat and stir in an oil bath at 75 °C for 10 h, and polymerize to obtain a white blocky solid material;

[0031] (3) Dry the obtained massive solid material in a vacuum oven at 60 °C for 8 h, and grind it evenly with an agate mortar to obtain a white powder material.

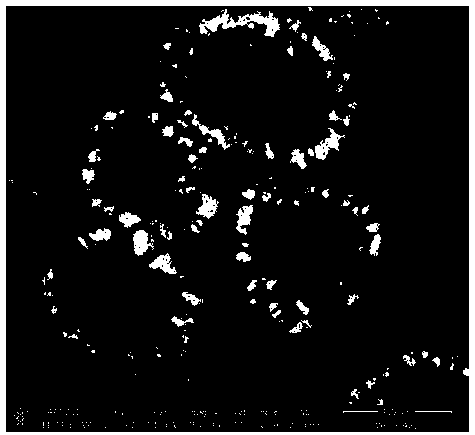

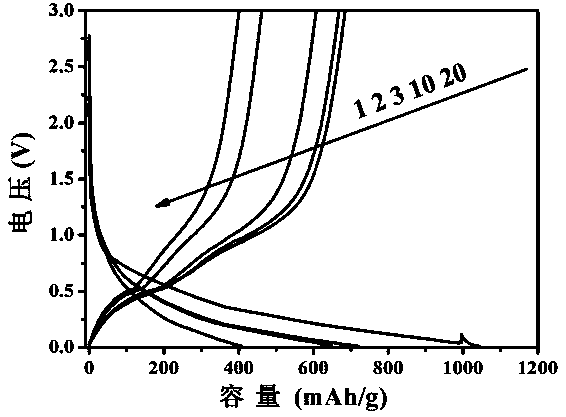

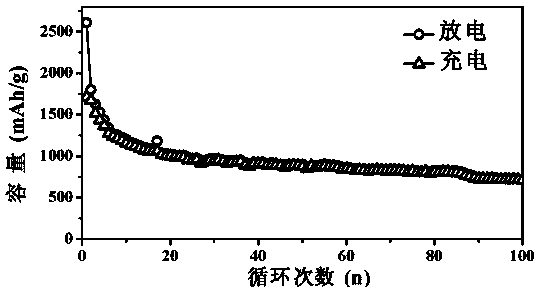

[0032] From figure 1 From the scanning electron microscope image of the composite material, it can be seen that the nano-germanium dioxide in the prepared composite material is uniformly dispersed in the polyionic liquid in the form of a ring. The shape is dispe...

Embodiment 2

[0035] The preparation method of the annular nano-germanium dioxide / polyionic liquid composite material of the present embodiment, the steps are as follows:

[0036] (1) First, dissolve 1.5 g of bisvinylimidazolium bromide ionic liquid and 1.5 g of germanium tetrachloride in 20 mL of absolute ethanol solution, and stir the above solution for 2 h;

[0037] (2) Add 1.5 g of divinylbenzene to the mixture prepared above, and stir for 2.5 h;

[0038] (3) Add 500 mg of azobisisobutyronitrile to the above-mentioned mixed solution, heat and stir in an oil bath at 70 °C for 10 h, and polymerize to obtain a yellow blocky solid material;

[0039] (4) Dry the obtained massive solid material in a vacuum oven at 60 °C for 8 h, and grind it evenly with an agate mortar to obtain a yellow powder material.

[0040] As can be seen from the scanning electron microscope images of the composite material in this example, the nano-germanium dioxide in the prepared composite material is uniformly dis...

Embodiment 3

[0043] The preparation method of the annular nano-germanium dioxide / polyionic liquid composite material of the present embodiment, the steps are as follows:

[0044] (1) First, 1.5 g of 1-vinyl-3-butylimidazolium bromide ionic liquid and 1.5 g of germanium tetrachloride were dissolved in 20 mL of absolute ethanol solution, and the above solution was fully stirred for 2 h;

[0045] (2) Add 1.5 g of divinylbenzene to the mixture prepared above, and stir for 2.5 h;

[0046] (3) Add 500 mg of azobisisobutyronitrile to the mixture prepared above, heat and stir in an oil bath at 70 °C for 15 h, and polymerize to obtain a yellow blocky solid material;

[0047] (4) Dry the obtained massive solid material in a vacuum oven at 60 °C for 8 h, and grind it evenly with an agate mortar to obtain a yellow powder material.

[0048] As can be seen from the scanning electron microscope images of the composite material in this example, the nano-germanium dioxide in the prepared composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com