Method for preparing monodisperse germanium nanocrystal by thermolysis

A technology of thermal decomposition and monodispersion, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of high cost, uneven particle size distribution of nanoparticles, harsh conditions of nanocrystalline materials, etc., and achieve cost Effects of low and high practical value and novel method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

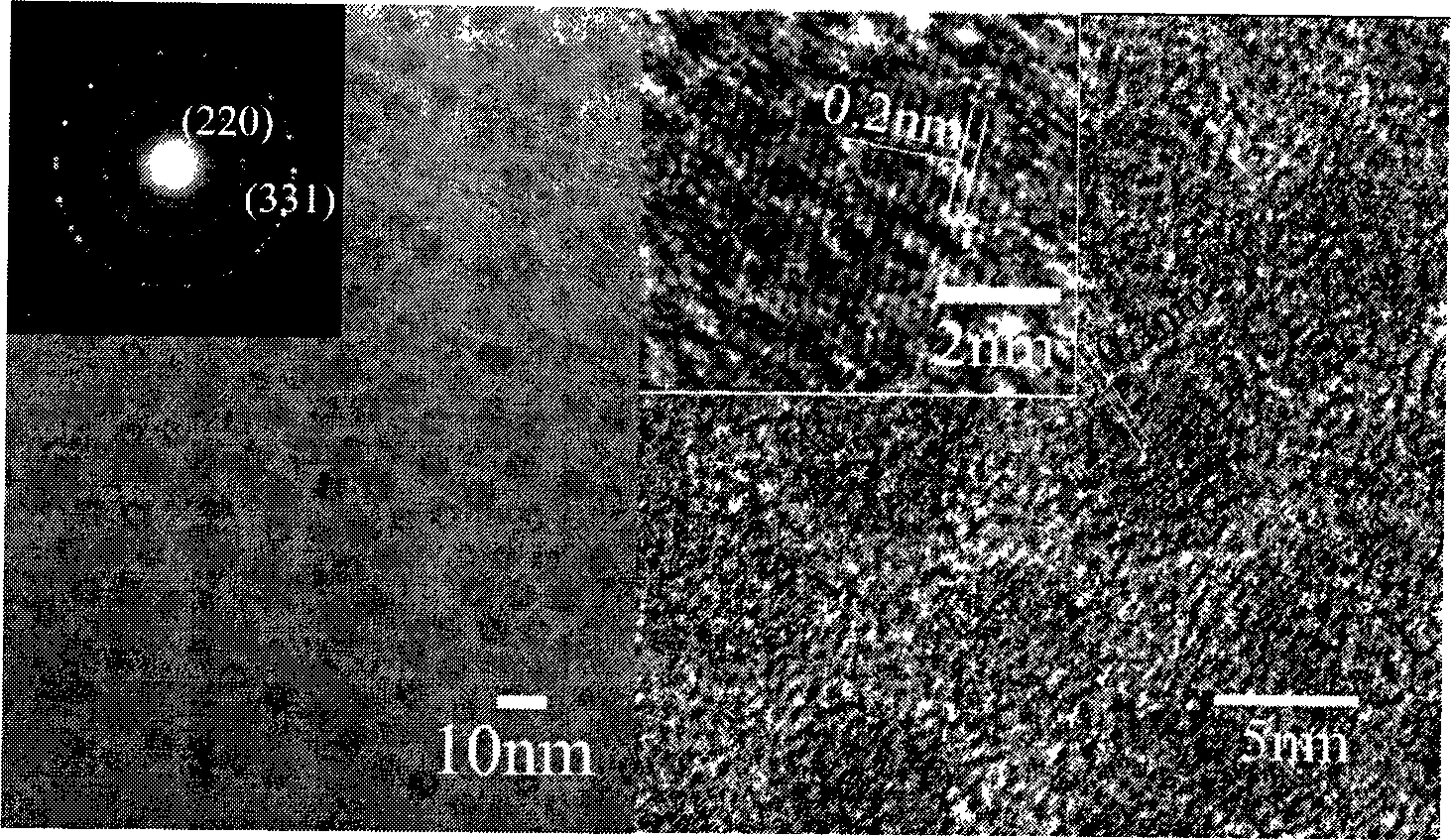

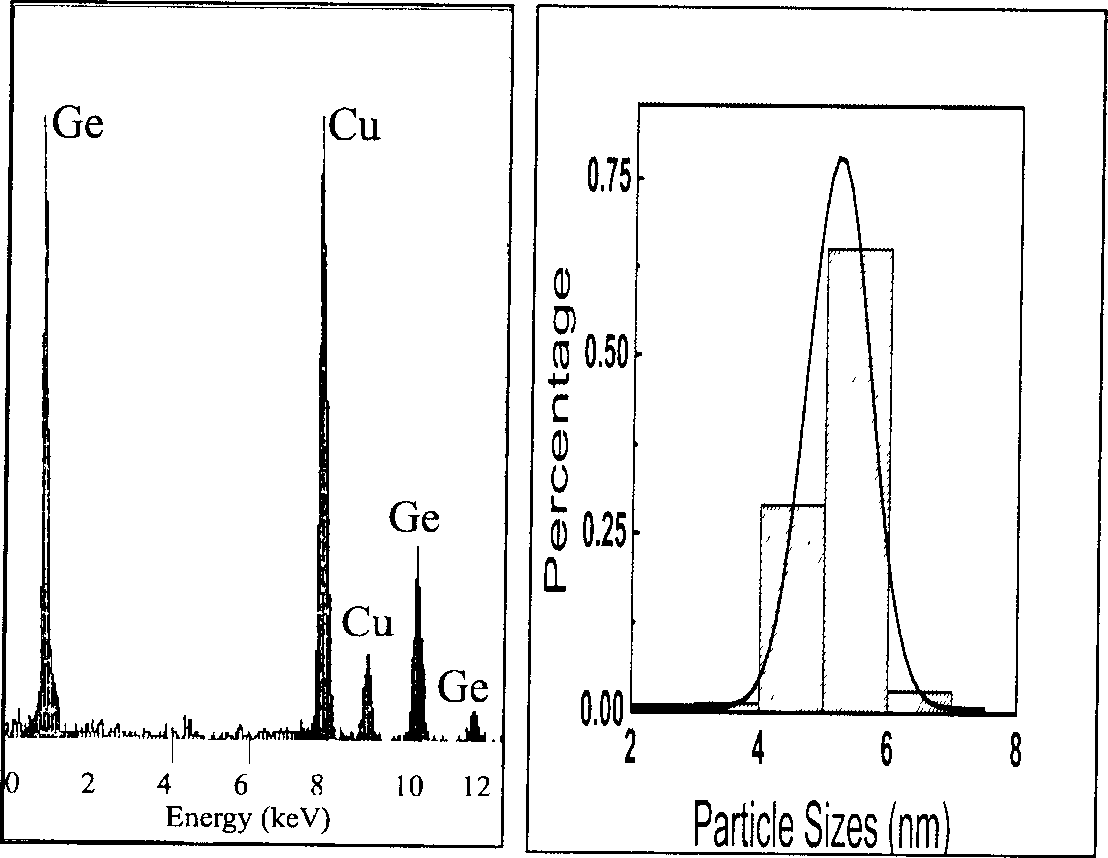

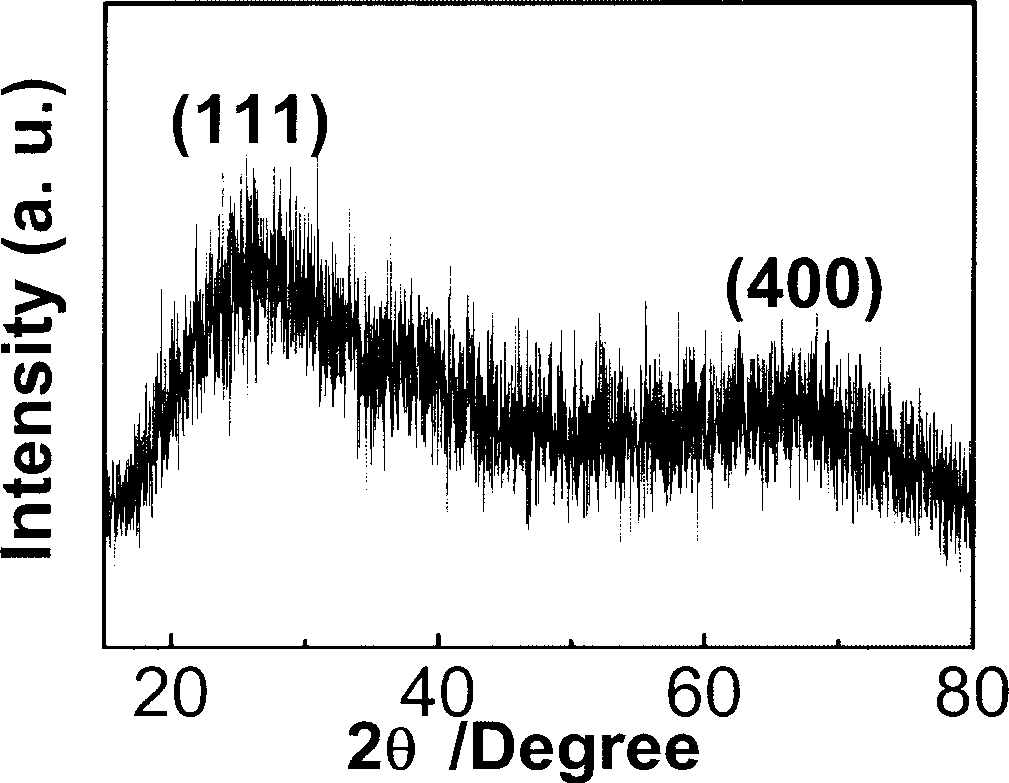

Embodiment 1

[0025] According to the preparation process, the air pressure is 1×10 -3 0.47ml of anhydrous GeCl in a Pa vacuum glove box 4 Slowly drop into 4ml of oleylamine, a large amount of heat will be released during the dropwise addition, after the dropwise addition is completed, react at 25°C for 30 minutes, and the obtained product is light yellow gel-like oleylamine germanium. The thermal decomposition process is as follows: 4ml of oleylamine, 4ml of oleic acid, and 16ml of octyl ether are mixed and added into a three-necked flask, and then the flask is heated to 100°C. In another three-necked flask, 2ml of oleylamine germanium and 10ml of octyl ether were mixed and heated to 80°C. Under the conditions of mechanical stirring and argon protection, the mixture of oleylamine germanium and octyl ether was quickly injected into component one through a medical syringe, and the mixture was heated to 290°C at a heating rate of 2°C / min at the same time, and at 290°C The reaction was stopp...

Embodiment 2

[0027] According to the preparation process, the air pressure is 1×10 -3 0.47ml of anhydrous GeCl in a Pa vacuum glove box 4 Slowly drop into 6ml of oleylamine, a lot of heat will be released during the dropwise addition, after the dropwise addition is completed, react at 30°C for 35 minutes, and the obtained product is light yellow gel-like oleylamine germanium. The thermal decomposition process is as follows: 4ml of oleylamine, 4ml of oleic acid, and 30ml of octyl ether are mixed and added into a three-necked flask, and then the flask is heated to 100°C. In another three-necked flask, 2ml of oleylamine germanium and 12ml of octyl ether were mixed and heated to 80°C. Under the conditions of mechanical stirring and argon protection, the mixture of oleylamine germanium and octyl ether was quickly injected into component one through a medical syringe, and the mixture was heated to 297°C at a heating rate of 1.5°C / min, and at 297°C The reaction was stopped after reflux for 4h. ...

Embodiment 3

[0029] According to the preparation process, the air pressure is 1×10 -3 0.47ml of anhydrous GeCl in a Pa vacuum glove box 4 Slowly drop into 8ml of oleylamine, a large amount of heat will be released during the dropwise addition, after the dropwise addition is completed, react at 30°C for 35 minutes, and the obtained product is light yellow gel-like oleylamine germanium. The thermal decomposition process is as follows: 4ml of oleylamine, 4ml of oleic acid, and 20ml of octyl ether are mixed and added into a three-necked flask, and then the flask is heated to 100°C. In another three-necked flask, 2ml of oleylamine germanium and 12ml of octyl ether were mixed and heated to 90°C. Under the condition of mechanical stirring and argon protection, the mixture of oleylamine germanium and octyl ether was quickly injected into component one through a medical syringe, and the mixture was heated to 300 °C at a heating rate of 2 °C / min at the same time, and at 300 °C The reaction was sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com