Optical fiber preform and preparation method thereof

A technology of optical fiber prefabricated rod and core rod, which is applied in the field of optical communication, can solve the problems of fiber attenuation, failure to reduce loss, and deterioration of bending performance, etc., and achieve the effects of large effective area, alleviating boundary effects, and reducing fiber loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

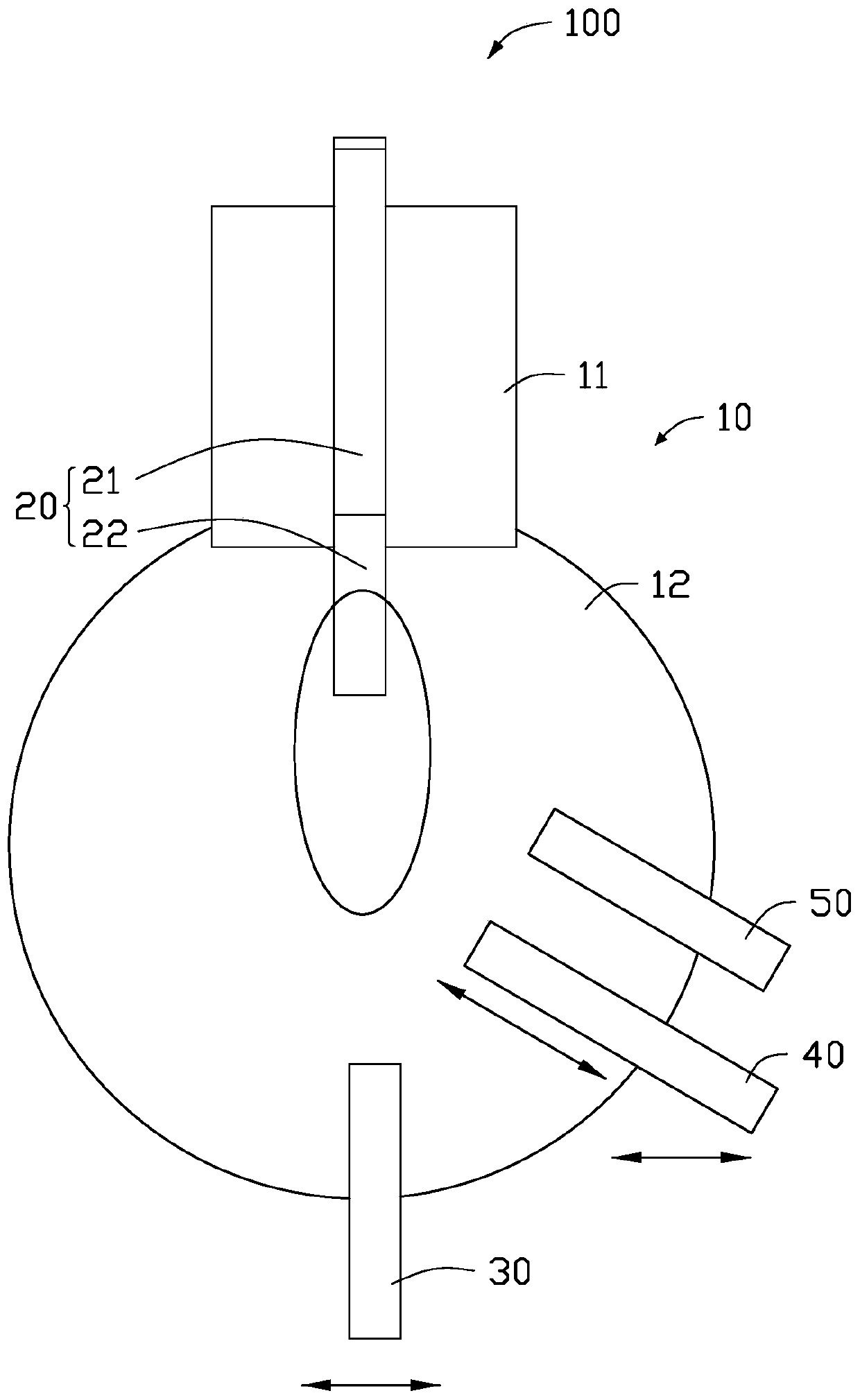

[0035] see Figure 4 , the present invention also provides a method for preparing an optical fiber preform, comprising the following steps:

[0036] Step S31, using a vapor deposition process to prepare a core rod, sequentially depositing through the first blowtorch, the second blowtorch and the third blowtorch, and injecting fluoride, silicon tetrachloride, combustible gas, inert gas and oxygen into the first blowtorch, Form the silicon dioxide loose body of fluorine element, pass oxygen, combustible gas, silicon tetrachloride, germanium tetrachloride and inert gas into the second torch, and form a core layer loose body on the surface of the silicon dioxide loose body. Oxygen, combustible gas, silicon tetrachloride and inert gas are fed into the three blowtorches to form a silicon dioxide inner cladding layer on the surface of the core layer loose body, and the core rod is obtained after the deposition is completed;

[0037] Step S32, performing dehydration and vitrification...

Embodiment 1

[0051] First, the angle of the first blowtorch is adjusted to 50°, the angle of the second blowtorch is adjusted to 40°, and SiF is introduced into the first blowtorch by vapor deposition. 4 、SiCl 4 、H 2 , KCl, Ar and O 2 , Ar as a carrier gas to bring KCl into the first blowtorch, wherein the flow of Ar is controlled at 60cc / min, SiF 4 The flow of gas is controlled at 100cc / min, and O is passed into the second blowtorch 2 、H 2 、SiCl 4 、GeCl 4 and Ar gas, where GeCl 4 The flow of gas is controlled at 50cc / min, and O is passed into the third blowtorch 2 、H 2 、SiCl 4 And Ar gas, deposited to form powder rods.

[0052] The deposited powder rods are dehydroxylated and vitrified and sintered in a sintering furnace. Among them, after the dehydration is completed and the glass transition temperature rises to 1250 °C, SiCl 4 Gas, the flow rate is 1g / min, the constant temperature time is 6h, and then SiF is introduced 4 Gas, the flow rate is 300cc / min, and the constant tem...

Embodiment 2

[0057] First, the angle of the first blowtorch is adjusted to 70°, and the angle of the second blowtorch is adjusted to 60°. By vapor deposition, SiF is introduced into the first blowtorch 4 、SiCl 4 、H 2 , KBr, Ar and O 2 , Ar as a carrier gas to bring KBr into the first blowtorch, wherein the flow of Ar is controlled at 100cc / min, SiF 4 The flow of gas is controlled at 150cc / min, and O is passed into the second blowtorch 2 、H 2 、SiCl 4 、GeCl 4 and Ar gas, where GeCl 4 The flow of gas is controlled at 80cc / min, and O is passed into the third blowtorch 2 、H 2 、SiCl 4 And Ar gas, deposited to form powder rods.

[0058] The deposited powder rods are dehydroxylated and vitrified and sintered in a sintering furnace. Among them, after the dehydration is completed and the glass transition temperature rises to 1250 °C, SiCl 4 Gas, the flow rate is 3g / min, the constant temperature time is 4h, and then SiF is introduced 4 Gas, the flow rate is 500cc / min, and the constant te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective area | aaaaa | aaaaa |

| Bending loss | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com