Ge (II) precursor as well as preparation method and application thereof

A technology of precursor and reaction, which is applied in the field of microelectronic materials, can solve problems such as the difficulty of obtaining germanium precursors, and achieve the effects of mild conditions, low energy consumption, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

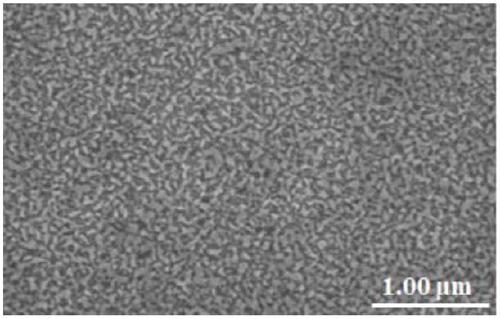

[0069] This embodiment provides a Ge(II) precursor for vapor deposition—bis(N-cyano-N-n-propylamine)germanium, the structure of which is shown in formula (a).

[0070]

[0071] Its preparation method is: under the protection of nitrogen, dissolve N-cyano-N-n-propylamine (0.80mmol, 0.110g) in anhydrous n-hexane to form a light yellow transparent solution. Add methyllithium ether solution (1.60M, 0.50mL) at -78°C, and the solution immediately becomes cloudy. After returning to 25°C, continue to stir and stir for 3 hours. There is no obvious change in the system. After the reaction is completed, filter and collect the filter residue, which is the product lithium salt, and store it in a glove box.

[0072] Weigh lithium salt (0.80mmol, 0.170g) in the glove box and dissolve it in anhydrous ether under the protection of nitrogen, transfer it to a constant pressure dropping funnel, and drop it into the germanium dichloride-dioxane complex at -78°C (0.40mmol, 0.090g) in ether solu...

Embodiment 2

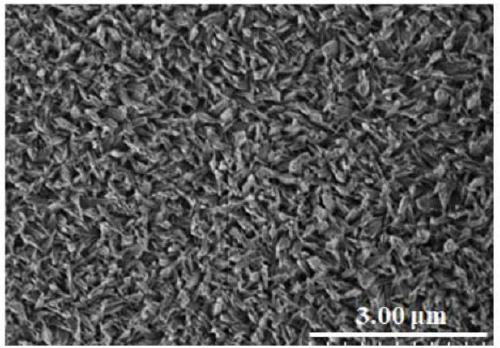

[0081] This embodiment provides a Ge(II) precursor for vapor deposition—bis(N-cyano-N-tert-butylamine)germanium, the structure of which is shown in formula (b).

[0082]

[0083] Its preparation method is: under the protection of nitrogen, dissolve N-cyano-N-tert-butylamine (0.80mmol, 0.130g) in anhydrous n-hexane to form a light yellow transparent solution. Add methyllithium ether solution (1.60M, 0.50mL) at -78°C, and the solution immediately becomes cloudy. After returning to 25°C, continue to stir and stir for 3 hours. There is no obvious change in the system. After the reaction is completed, filter and collect the filter residue, which is the product lithium salt, and store it in a glove box.

[0084] Weigh lithium salt (0.80mmol, 0.190g) in the glove box and dissolve it in anhydrous ether under the protection of nitrogen, transfer it to a constant pressure dropping funnel, and drop it into the germanium dichloride-dioxane complex at -78°C (0.40mmol, 0.090g) in ether ...

Embodiment 3

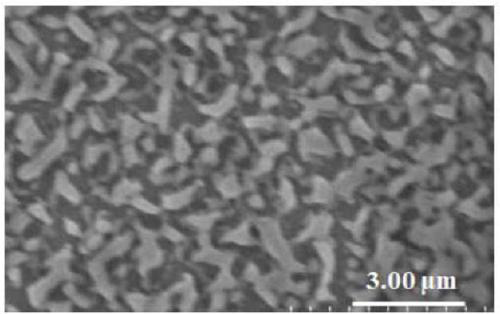

[0093] This embodiment provides a Ge(II) precursor for vapor deposition—bis(N-cyano-N-p-tolylamine)germanium, the structure of which is shown in formula (c).

[0094]

[0095] Its preparation method is: under the protection of nitrogen, dissolve N-cyano-N-p-tolylamine (0.80mmol, 0.260g) in anhydrous n-hexane to form a light yellow transparent solution. Add methyllithium ether solution (1.60M, 0.50mL) at -78°C, and the solution immediately becomes cloudy. After returning to 25°C, continue to stir and stir for 3 hours. There is no obvious change in the system. After the reaction is completed, filter and collect the filter residue, which is the product lithium salt, and store it in a glove box.

[0096] Lithium salt (0.80mmol, 0.30g) was weighed in the glove box and dissolved in anhydrous ether under nitrogen protection, transferred to a constant pressure dropping funnel, and dropped into the germanium dichloride-dioxane complex at -78°C (0.40mmol, 0.090g) in ether solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com