A method for leaching germanium from germanium chloride distillation calcium slag

A technology of chlorinated distillation and calcium slag, applied in the field of hydrometallurgy, can solve the problems of waste of resources, corrosion of volatilization furnace, high cost, and achieve the effect of avoiding the generation of silica gel, reducing consumption and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

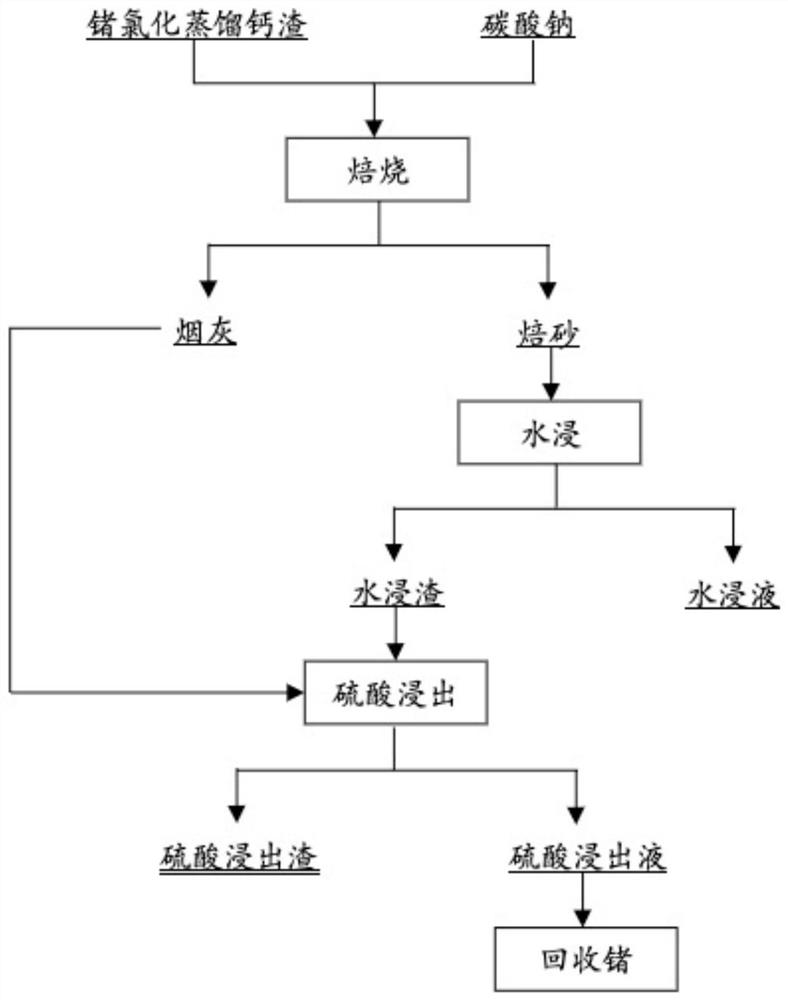

Method used

Image

Examples

Embodiment 1

[0052] The main components of the germanium chloride distillation calcium slag used in this embodiment are Ca: 15.20%, Si: 24.30%, Pb: 6.83%, S: 8.65%, and Ge: 0.85% in mass percentage. Industrial grade sulfuric acid, where H 2 SO 4 ≥98%; industrial grade sodium carbonate, of which Na 2 CO 3 ≥98%.

[0053] This embodiment provides a method for leaching germanium from germanium chloride distillation calcium slag, which includes:

[0054] S1: Weigh 400g of calcium slag from germanium chloride distillation and 200g of sodium carbonate, mix it evenly, put it into the furnace, roast it at 800°C for 3 hours, and get 484.0g of calcined sand and 31.2g of dust after cooling;

[0055] S2: immerse 484.0 g of calcined sand obtained after roasting in water, control liquid-solid ratio to 8 mL / g, temperature at 40°C, leaching time for 3 hours, stirring speed at 500 rpm, and filter to obtain 242.0 g of water-leaching residue after leaching;

[0056] S3: Leach 242.0g water leaching residu...

experiment example 1

[0058] The Ge content in the sulfuric acid leaching slag provided by Analysis Example 1 was 0.30%, and the Ge leaching rate was 92.2%.

Embodiment 2

[0060] The main components of the germanium chloride distillation calcium slag used in this embodiment are Ca: 9.20%, Si: 16.80%, Pb: 8.93%, S: 5.45%, and Ge: 0.74% in mass percentage. Industrial grade sulfuric acid, where H 2 SO 4 ≥98%; industrial grade sodium carbonate, of which Na 2 CO 3 ≥98%.

[0061] This embodiment provides a method for leaching germanium from germanium chloride distillation calcium slag, which includes:

[0062] S1: Weigh 600g of calcium slag from germanium chloride distillation and mix it evenly with 300g of sodium carbonate, put it into the furnace, roast it at 900°C for 2 hours, and get 748.5g of calcined sand and 59.4g of soot after cooling.

[0063] S2: Soak 748.5g of calcined sand obtained after calcination in water, control liquid-solid ratio to 6mL / g, temperature at 50°C, leaching time for 2h, stirring speed at 400rpm, filter after leaching to obtain 331.3g of water-leaching residue.

[0064] S3: Leach 313.3g water leaching residue and 59.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com