Preparation method of germanium dioxide powder

A germanium dioxide and powder technology, which is applied in the field of semiconductor oxide preparation technology, can solve the problems of entering the surrounding environment, increase production costs, environmental pollution, etc., and achieve the effects of being environmentally friendly, reducing washing water, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

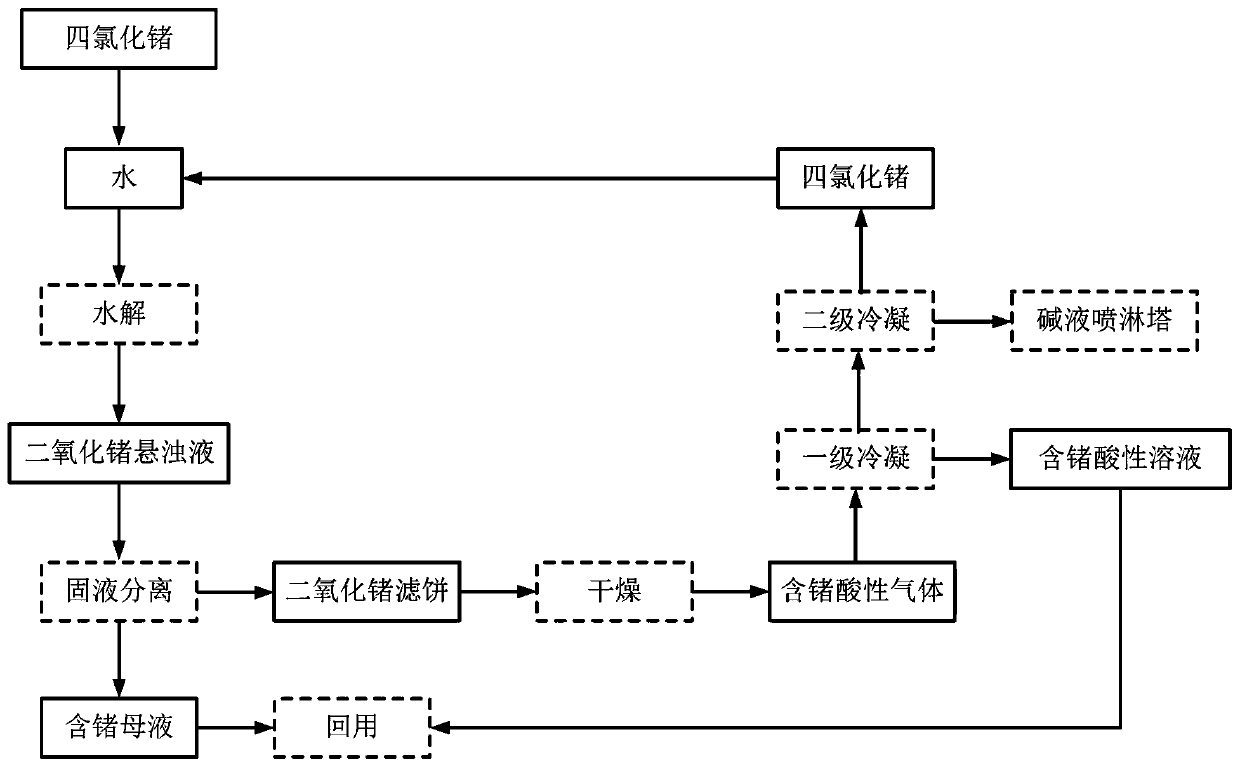

[0023] The preparation method of the germanium dioxide powder provided in the following examples uses germanium tetrachloride hydrolysis to obtain a germanium dioxide suspension, solid-liquid separation to obtain a germanium dioxide filter cake, and then germanium dioxide filter cake. The germanium dioxide powder is obtained by drying and pulverizing, which greatly reduces the water consumption for washing the filter cake of germanium dioxide. The escape and loss of germanium. At the same time, the germanium tetrachloride obtained after the germanium-containing acid gas is condensed and the germanium-containing acidic solution are recycled, the germanium tetrachloride is returned to the hydrolysis system for hydrolysis, and the germanium-containing acidic solution can be returned to the germanium leaching process for production or The germanium contained therein is recovered by using methods such as tannin precipitation and extraction, so as to overcome the shortcomings of the...

Embodiment 1

[0026] A kind of preparation method of germanium dioxide powder, see figure 1 As shown, add 40L of secondary reverse osmosis high-purity water to the 100L enamel hydrolysis kettle, put -10°C ethylene glycol freezing liquid into the interlayer of the enamel kettle, start the agitator to stir, and start to use the peristaltic pump to pump the high-purity water when the water temperature drops to 10°C Add germanium tetrachloride, flow rate is 80ml / min, after 10L germanium tetrachloride is all added, continue to stir for 30min, obtain the suspension of germanium tetrachloride, utilize vacuum filtration, obtain the mother liquor containing germanium and germanium dioxide Wet filter cake, transfer the wet filter cake into an electric heating drying oven at a drying temperature of 200° C., and pulverize the dried germanium dioxide with a pulverizer to obtain germanium dioxide powder.

[0027] During the drying process, germanium-containing acid gases including hydrogen chloride, germ...

Embodiment 2

[0032] A kind of preparation method of germanium dioxide powder, see figure 1 As shown, add 60L of secondary reverse osmosis high-purity water to the 100L enamel hydrolysis kettle, put -10°C ethylene glycol freezing liquid into the interlayer of the enamel kettle, start the stirrer to stir, and start to use the peristaltic pump to pump the high-purity water when the water temperature drops to 0°C Add germanium tetrachloride at a flow rate of 50ml / min. After 10L of germanium tetrachloride is added, continue to stir for 30 minutes to obtain a suspension of germanium tetrachloride. Vacuum filtration is used to obtain germanium-containing mother liquor and germanium dioxide. Wet filter cake, transfer the wet filter cake into an electric heating drying oven at a drying temperature of 300° C., and pulverize the dried germanium dioxide with a pulverizer to obtain germanium dioxide powder.

[0033] During the drying process, germanium-containing acid gases including hydrogen chloride,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com