Technique for recovering germanium from electric furnace germanium slag

A germanium slag and electric furnace technology is applied in the technical field of recovering germanium from electric furnace germanium slag, which can solve the problems of high processing cost, low production efficiency, difficult operation and the like, and achieves high recovery rate, stable recovery rate and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

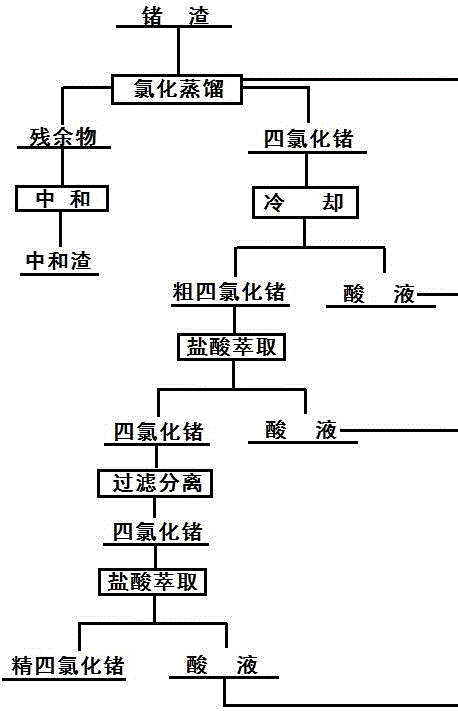

Method used

Image

Examples

Embodiment 1

[0025] In this example, the stationary phase and separation column for filtration are mainly prepared. The stationary phase is prepared by the following method: first, under the condition of 80°C, use 1 mol of hydrochloric acid to acidify the silica gel powder with a particle size of 1 μm, and the treatment time is 12 hours. After cooling to room temperature, filter, wash and Dry the pretreated silica gel powder; then, add the pretreated silica gel powder into a vacuum reactor filled with anhydrous toluene, and then add γ-aminopropyltriethoxysilane dropwise at 60°C , stirred and reacted for 12 h; then added tri-n-octylamine, stirred and reacted for 8 hours; then added methacrylic acid, stirred and reacted for 6 hours; then filtered, washed and dried to obtain the stationary phase; wherein, the pretreatment The mass ratio of silica gel powder, γ-aminopropyltriethoxysilane, tri-n-octylamine and methacrylic acid is 100:10:12:4.

[0026] The separation column used is a cylindrica...

Embodiment 2

[0028] In this embodiment, the content of germanium in the germanium slag of electric furnace is 4.93wt%, the content of lead is 30.2wt%, the content of zinc is 12.5wt%, the content of arsenic is 7.12wt%, and the content of copper is 1.65wt%, The content of iron is 18.1, in addition to some other components. Add HCl containing 50g / L, FeCl 20g / L in the reaction kettle 3 , 15g / L of H 2 o 2and an acid solution with the balance of water; then, add 500 g of the above-mentioned electric furnace germanium slag under stirring conditions, and the mass ratio of the acid solution to the electric furnace germanium slag is 10:1; Until the introduced chlorine no longer absorbs; then the temperature is raised to 90°C, and germanium tetrachloride is distilled to obtain a gas containing germanium tetrachloride. The gas containing germanium tetrachloride is cooled to room temperature to obtain crude germanium tetrachloride liquid, which is extracted and filtered. The concentration of hydroc...

Embodiment 3

[0030] In this embodiment, the content of germanium in the germanium slag of electric furnace is 5.17wt%, the content of lead is 26.9wt%, the content of zinc is 15.1wt%, the content of arsenic is 8.73wt%, and the content of copper is 1.65wt%, The content of iron is 18.3, in addition to some other components. Add HCl containing 48g / L, FeCl 20g / L in the reaction kettle 3 , 20g / L of H 2 o 2 and an acid solution with the balance of water; then, add 500 g of the above-mentioned electric furnace germanium slag under stirring conditions, and the mass ratio of the acid solution to the electric furnace germanium slag is 10:1; Until the introduced chlorine no longer absorbs; then the temperature is raised to 85°C, and germanium tetrachloride is distilled to obtain a gas containing germanium tetrachloride. The gas containing germanium tetrachloride is cooled to room temperature to obtain crude germanium tetrachloride liquid, which is extracted and filtered. The concentration of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Column length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com