Patents

Literature

48results about How to "High and stable recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering germanium from zinc dross

ActiveCN101760653ANo pollution in the processSolve the technical problems of recyclingProcess efficiency improvementIndiumEvaporation

Then invention relates to a method for recovering germanium from zinc dross, belonging to the technical field of non-ferrous metallurgy. After the secondary extracted zinc is leached by adopting the wet method, and the leached dross can be pre-treated, the germanium can be converted into the germanic from the low-valence in metal or germanium monoxide. Namely, hydrogen peroxide is used for oxidizing germanium, lead, indium, arsenic and other elements in the hydrochloric acid medium, so that the elements can be oxidized from low valence to high valence; the lead, indium, arsenic, gallium and the like react into solution, the low-valence germanium wrapped by the elements can be exposed and oxidized to be the germanic by the hydrogen peroxide under the acid condition into hydrochloric acid solution, and the germanic can escape in a form of germanium tetrachloride by evaporation, so as to realize the separation with other purities; and then, the separated germanium tetrachloride is purified and hydrolyzed, so as to prepare germanium dioxide. In the zinc dross with the germanic being more than 2.0%, the recovery rate of the germanic can reach more than 98%; in the zinc dross with the germanic being more than 1.0-2.0%, the recovery rate of the germanic can reach more than 95%; and in the zinc dross with the germanic being 0.1-1.0%, the recovery rate of the germanic can reach more than 90%.

Owner:YUNNAN WUXIN IND

Method for reclaiming indium from waste mercury-free basic zinc-manganese battery

InactiveCN101104890AHigh and stable recoveryHigh purityPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention discloses a method for recycling indium from waste Hg-free alkaline zinc manganese dioxide battery, which comprises the following steps: separating and extracting the cathode material from waste Hg-free alkaline zinc manganese dioxide battery, dissolving with an acid, adding a reducing agent to replace sponge indium, and smelting the sponge indium to obtain indium ingots, the filtrate being used for electrolytic zinc process; or alternatively adjusting the pH value of the solution to 5 with a base solution after acid dissolution to allow the precipitation of In(OH)3, filtering to separate the filtrate used for electrolytic zinc process and the precipitate used as electrolyte after acid dissolution, and electrolyzing to obtain pure indium. Based on the existing state of indium in the waste Hg-free alkaline zinc manganese dioxide battery and the practical recovery of waste Hg-free alkaline zinc manganese dioxide battery, the invention realizes the recycle of indium and has the advantages of simple process, easy application, high and stable recovery rate of indium, less use of chemical additives in the recycle process, no secondary pollution, and high purity of extracted metal indium. Therefore, the invention realizes the cyclic regeneration of cathode material of waste alkaline zinc manganese dioxide battery and is better in economic benefit and environment-protection value.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for extracting indium-zinc alloy from waste mercury-free basic zinc-manganese battery

The invention discloses a method for extracting indium-zinc alloy from waste Hg-free alkaline zinc manganese dioxide battery, which comprises separating and extracting cathode substances from waste Hg-free alkaline zinc manganese dioxide battery, dissolving with a coordination agent containing zinc ions, electrolyzing the filtrate to obtain zinc, and smelting the insoluble substances to obtain indium-zinc alloy. Based on the existing state of indium in waste Hg-free alkaline zinc manganese dioxide battery and the practical recovery of waste Hg-free alkaline zinc manganese dioxide battery, the invention realizes the indium recovery and has the advantages of simple process, easy application, high and stable recovery rate of indium, less use of chemical additives in the recovery process, and no secondary pollution. The recycled indium-zinc alloy (indium content of 0.1-99.9 percent) can be used as a raw material of cathode material (indium-containing zinc powder) in the production of Hg-free alkaline manganese battery. The invention realizes the cyclic regeneration of cathode material of waste alkaline zinc manganese dioxide battery, and the industrial output value of the extract is far larger than the recovery and production costs, therefore, the invention is better in economic benefit and high environment-protection value.

Owner:SOUTH CHINA NORMAL UNIVERSITY

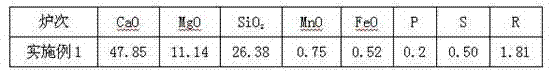

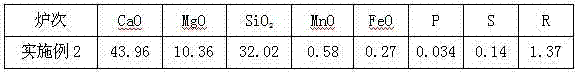

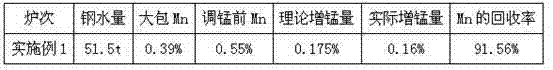

Method for alloying manganese ore in LF (ladle furnace)

InactiveCN102758066AReduce the amount addedIncrease electricity billProcess efficiency improvementSteelmakingAlloy

The invention relates to a method for alloying manganese ore in an LF (ladle furnace) furnace, and belongs to the field of steel-making production technologies. The technical scheme is as follows: the manganese ore is added to a ladle to be used as the top slag or added along with the slag in the LF furnace when a converter performs steel tapping; the LF furnace performs arcing and slagging, and carborundum-made reducing slag is synchronously added, and white slag is maintained; after the completion of manganese reduction, the refining is finished. Manganese ore is added with the proportioning of 3 to 6 kg / t; the manganese ore replaces wollastonite and fluorite, as well as replacing some silicomanganese, thus the quantity of added silicomanganese can be reduced; and the quantity of reduced replaced silicomanganese is 2.2 to 4.5 kg / t. According to the method, the manganese ore which is low in cost is applied to the LF furnace for alloying for the first time, and the silicomanganese or ferromanganese high in cost is replaced; the recovery rate of manganese is more than 90%, therefore, the cost of steelmaking is obviously reduced; and meanwhile, the manganese ore has high effect on slagging in the LF furnace, so the manganese ore can replace some fluorite for reducing the environmental pollution and erosion on wrapping liner.

Owner:HEBEI IRON AND STEEL

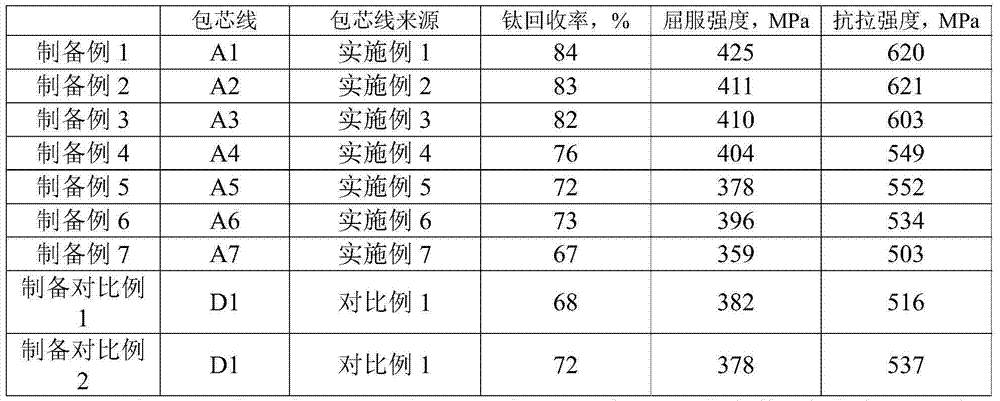

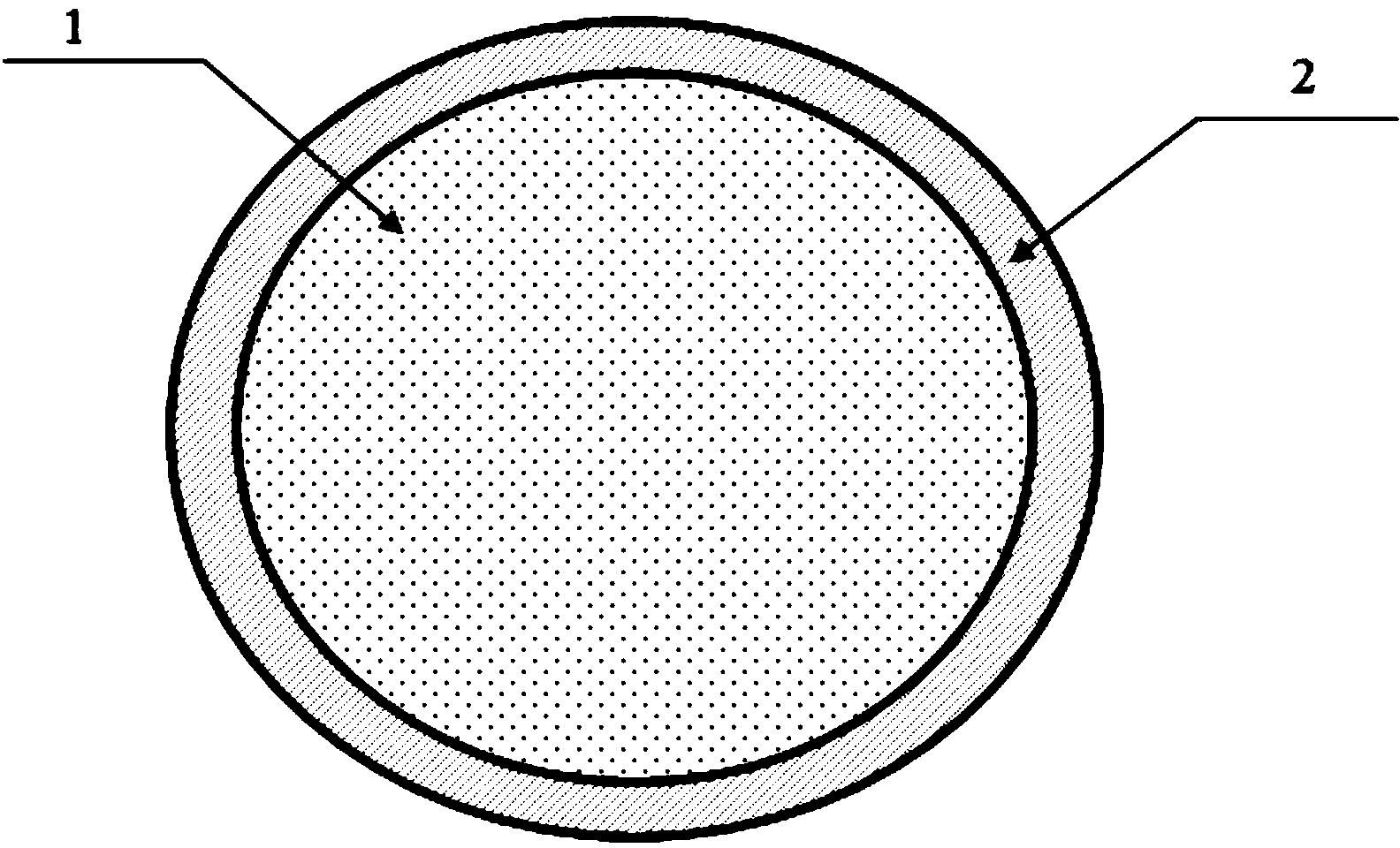

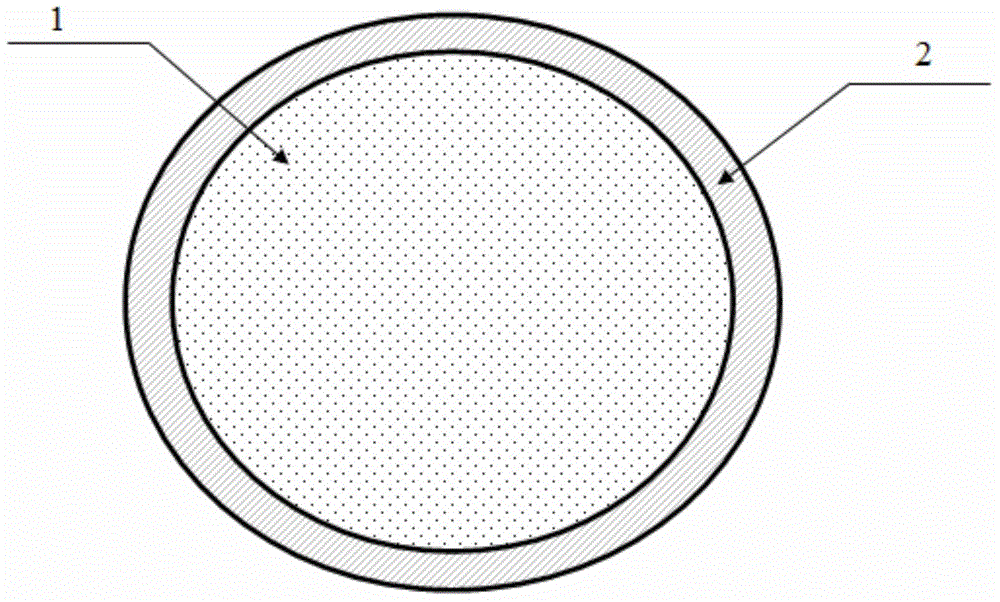

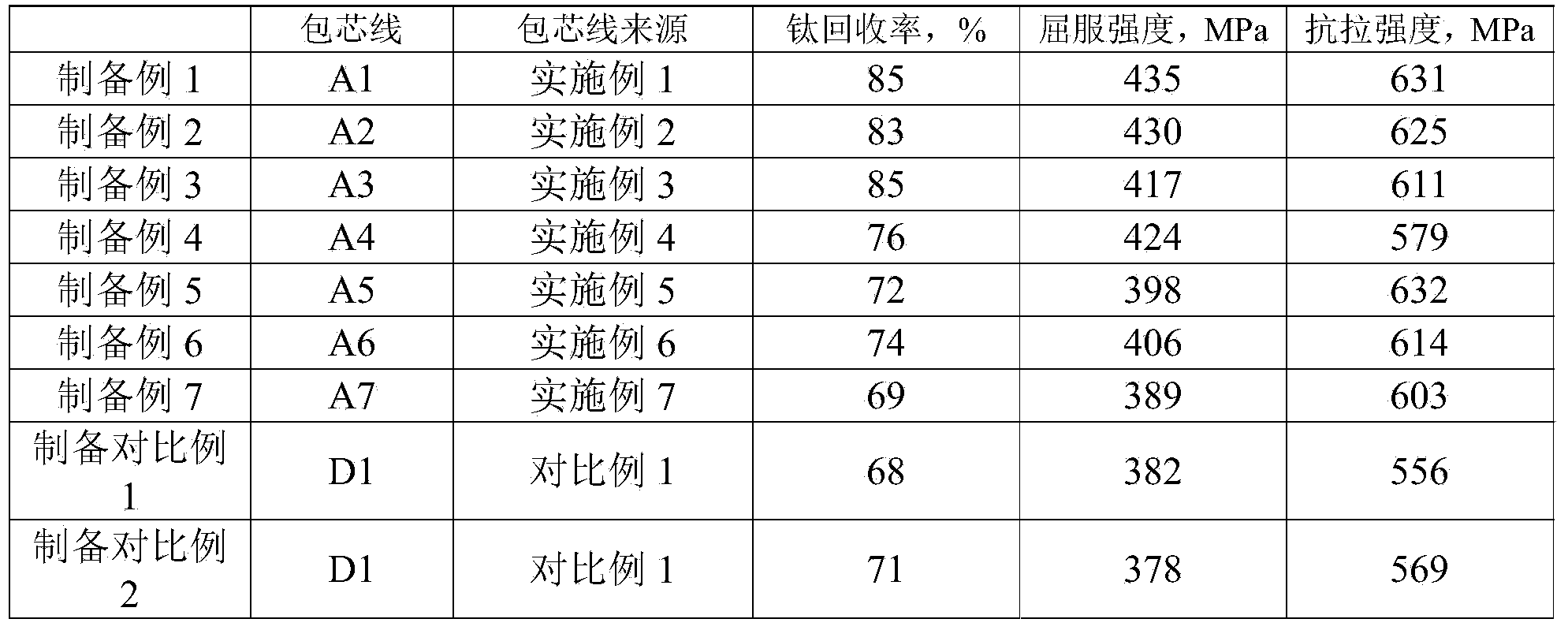

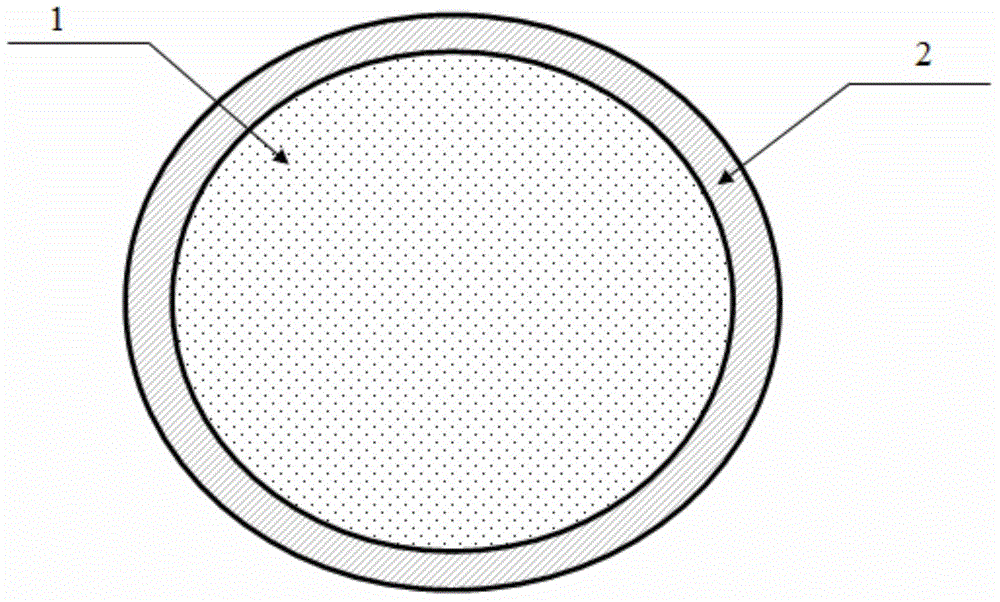

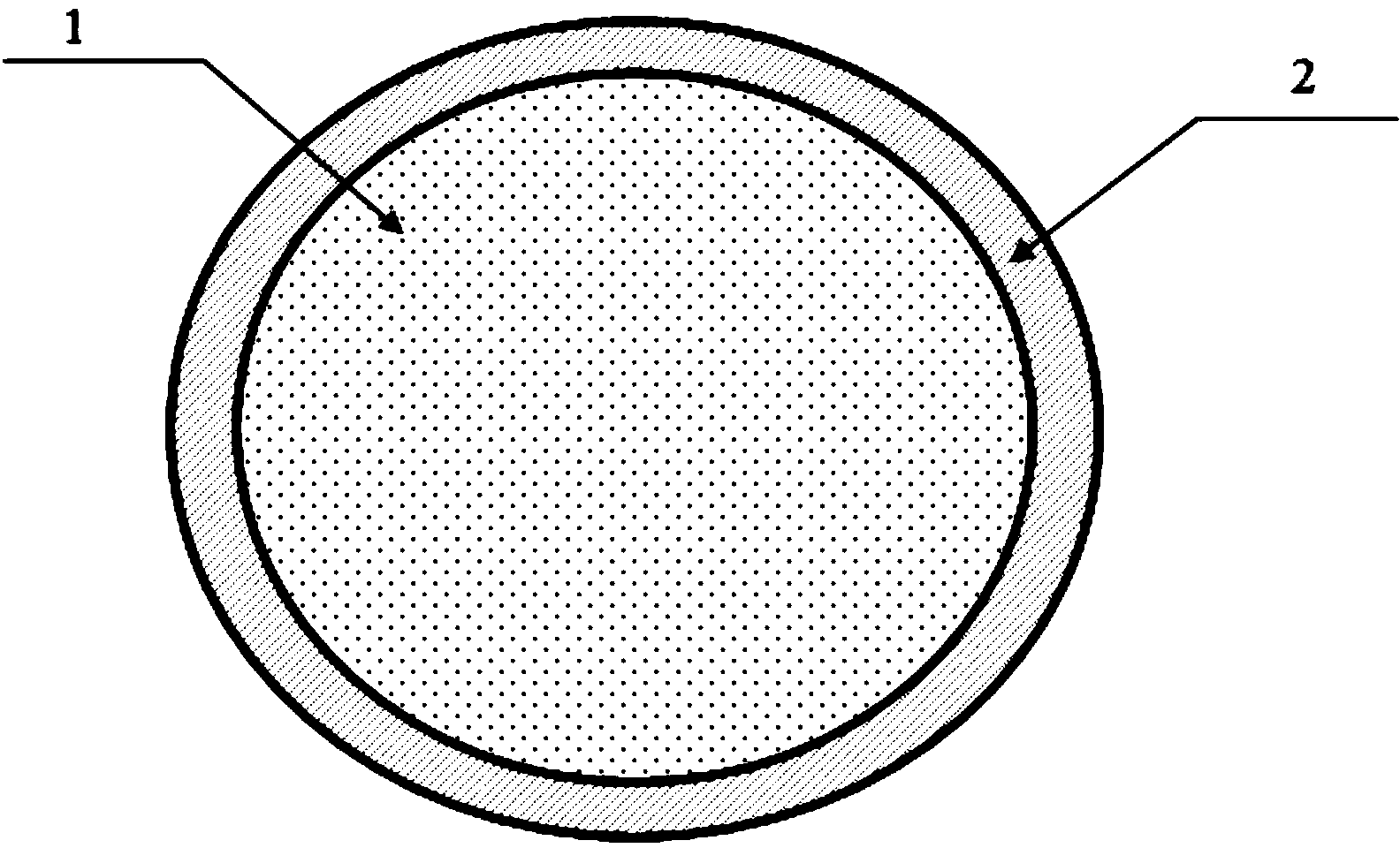

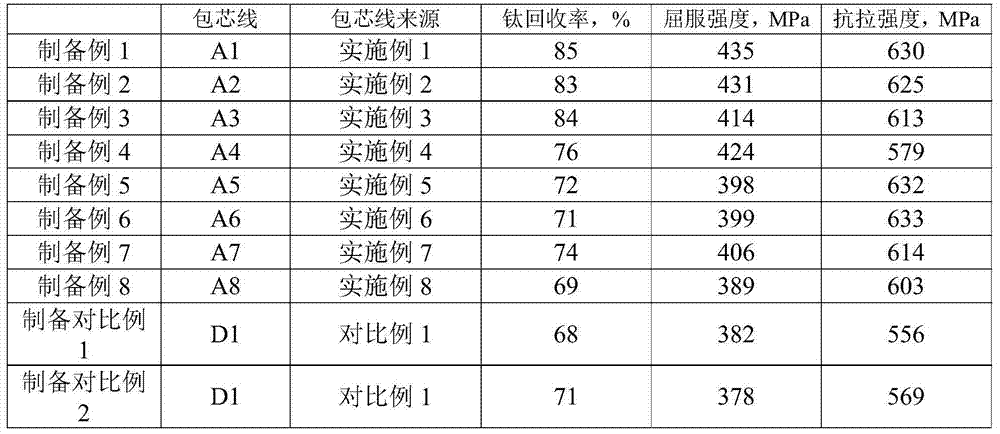

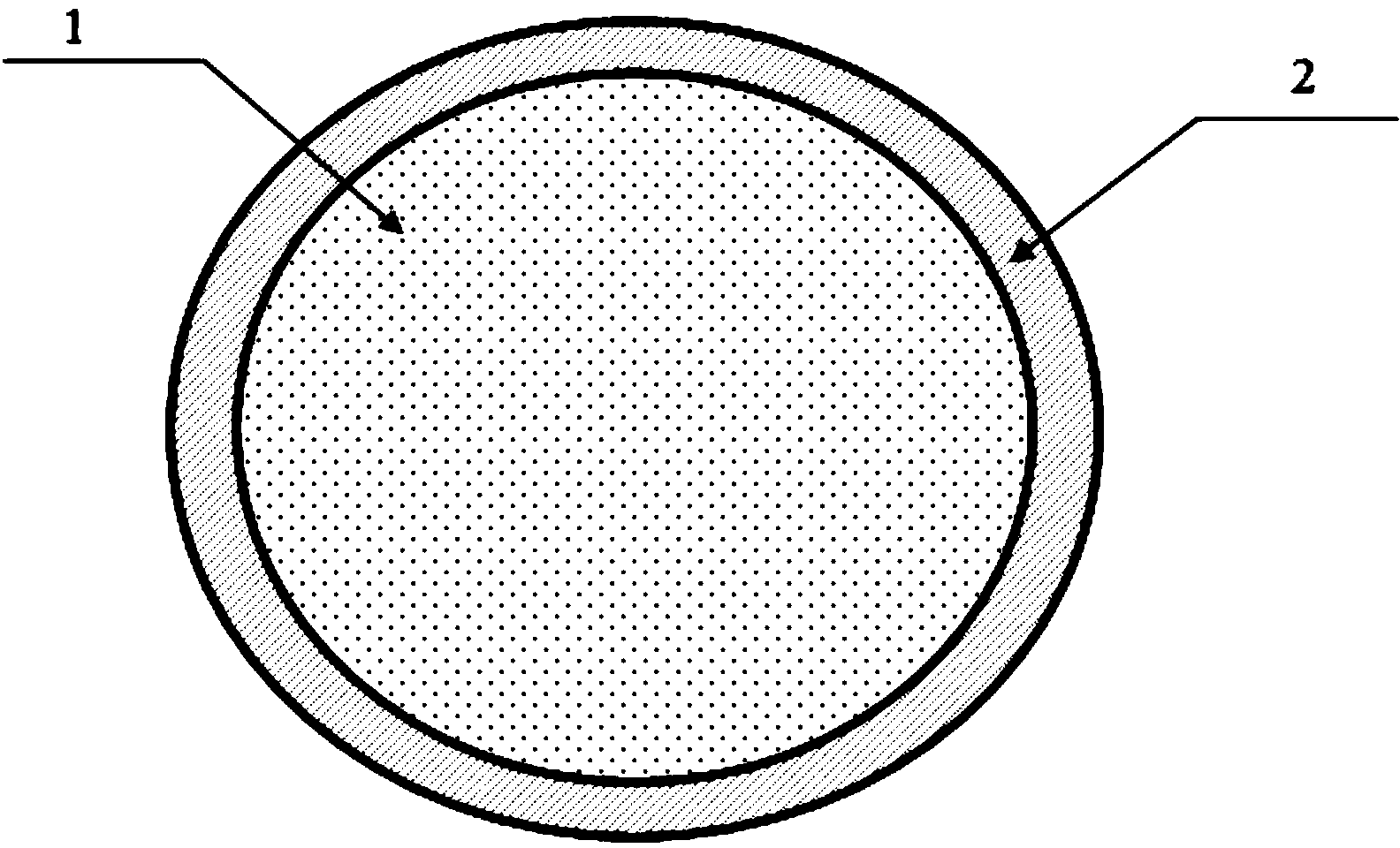

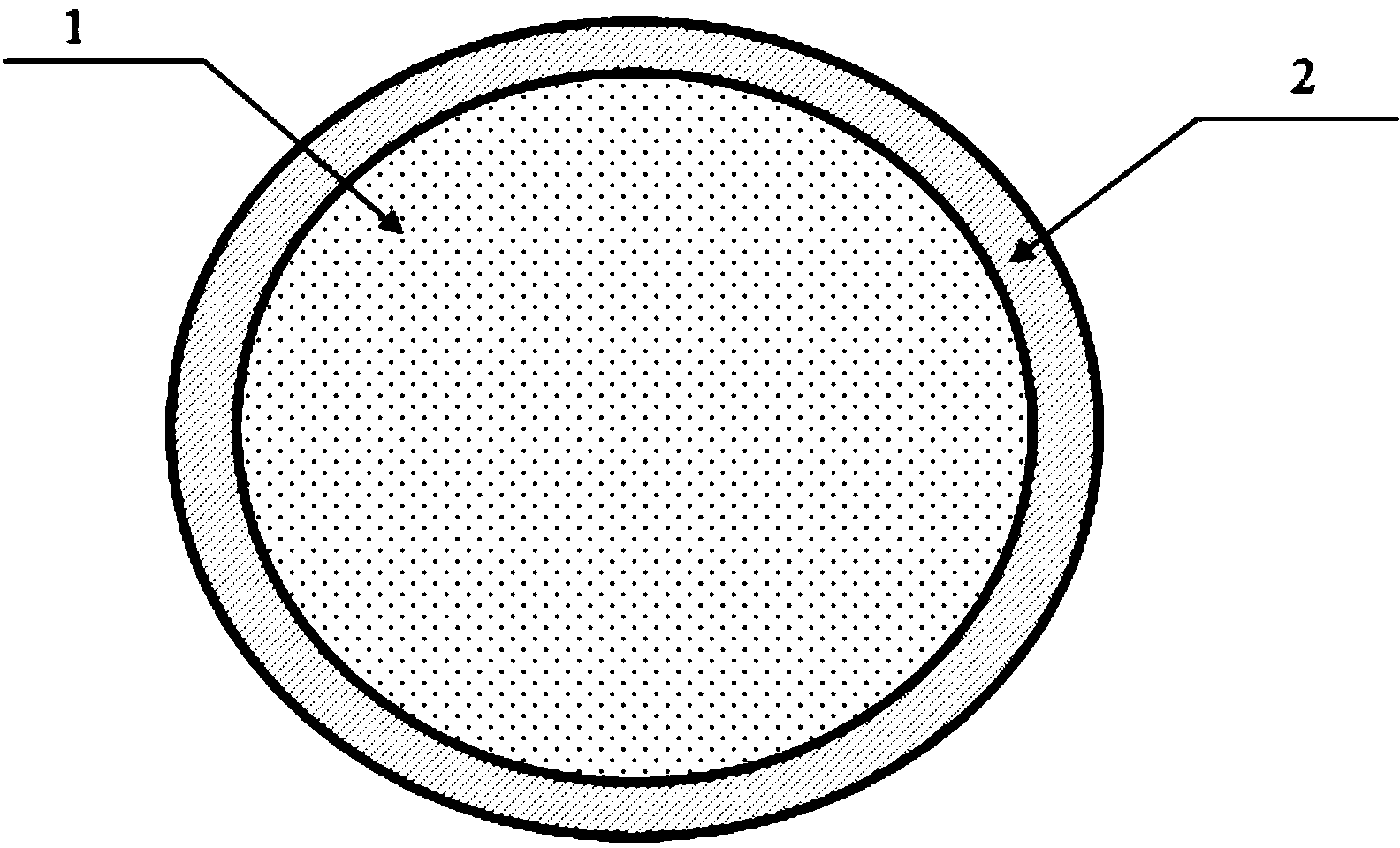

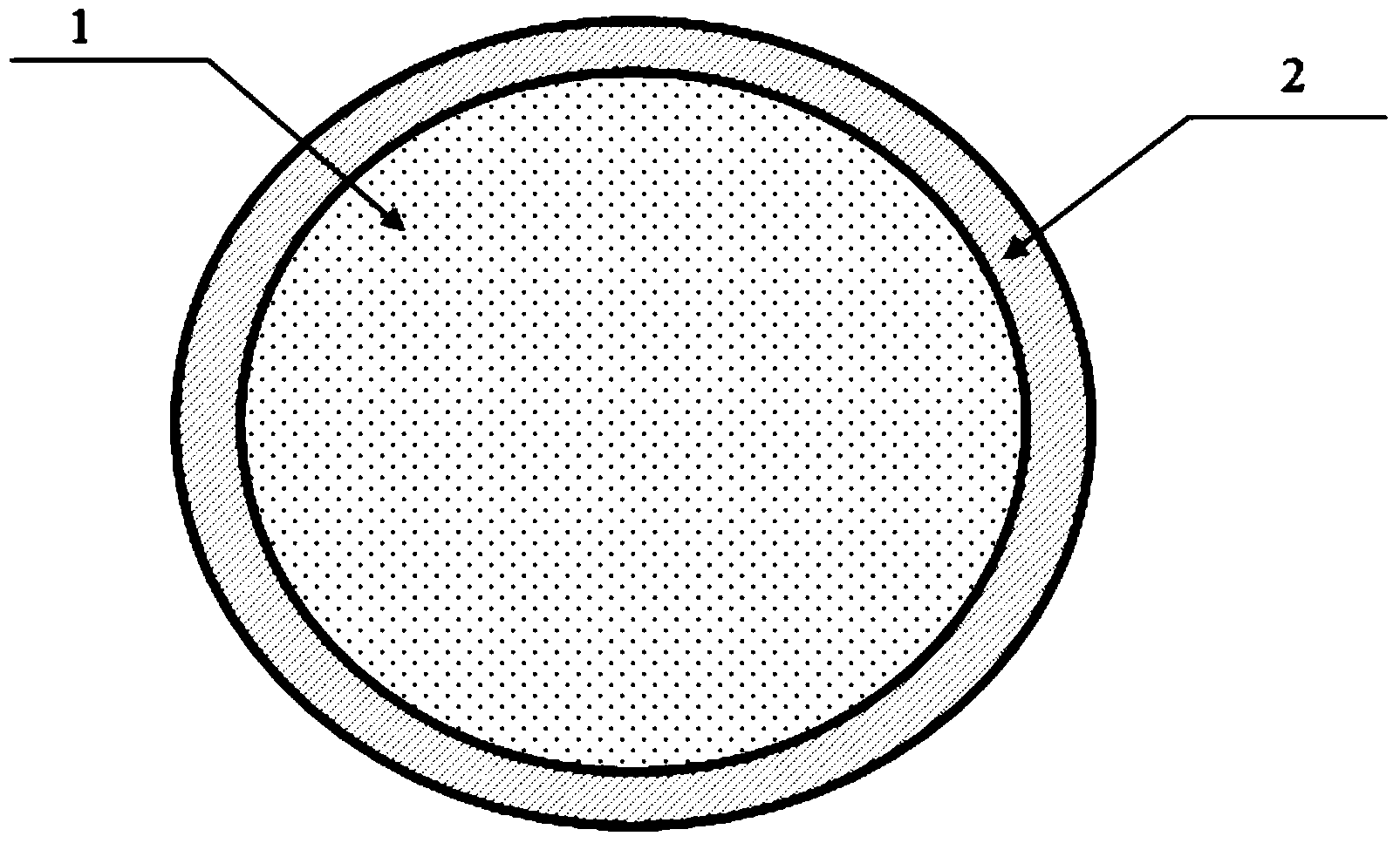

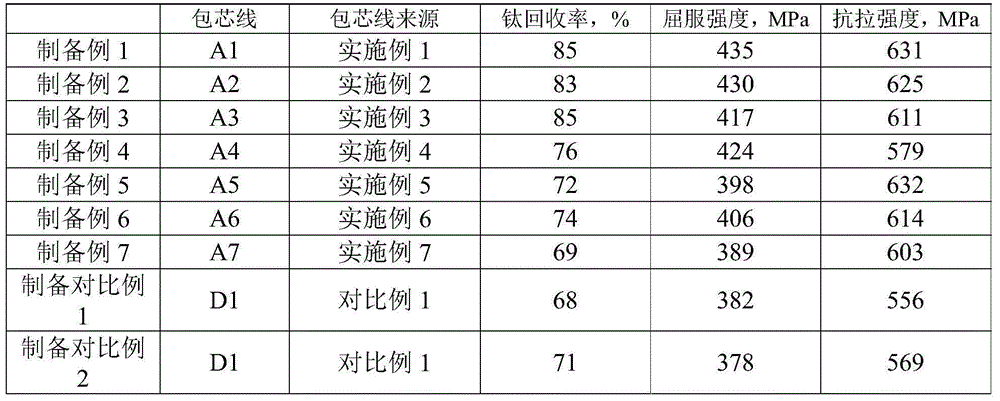

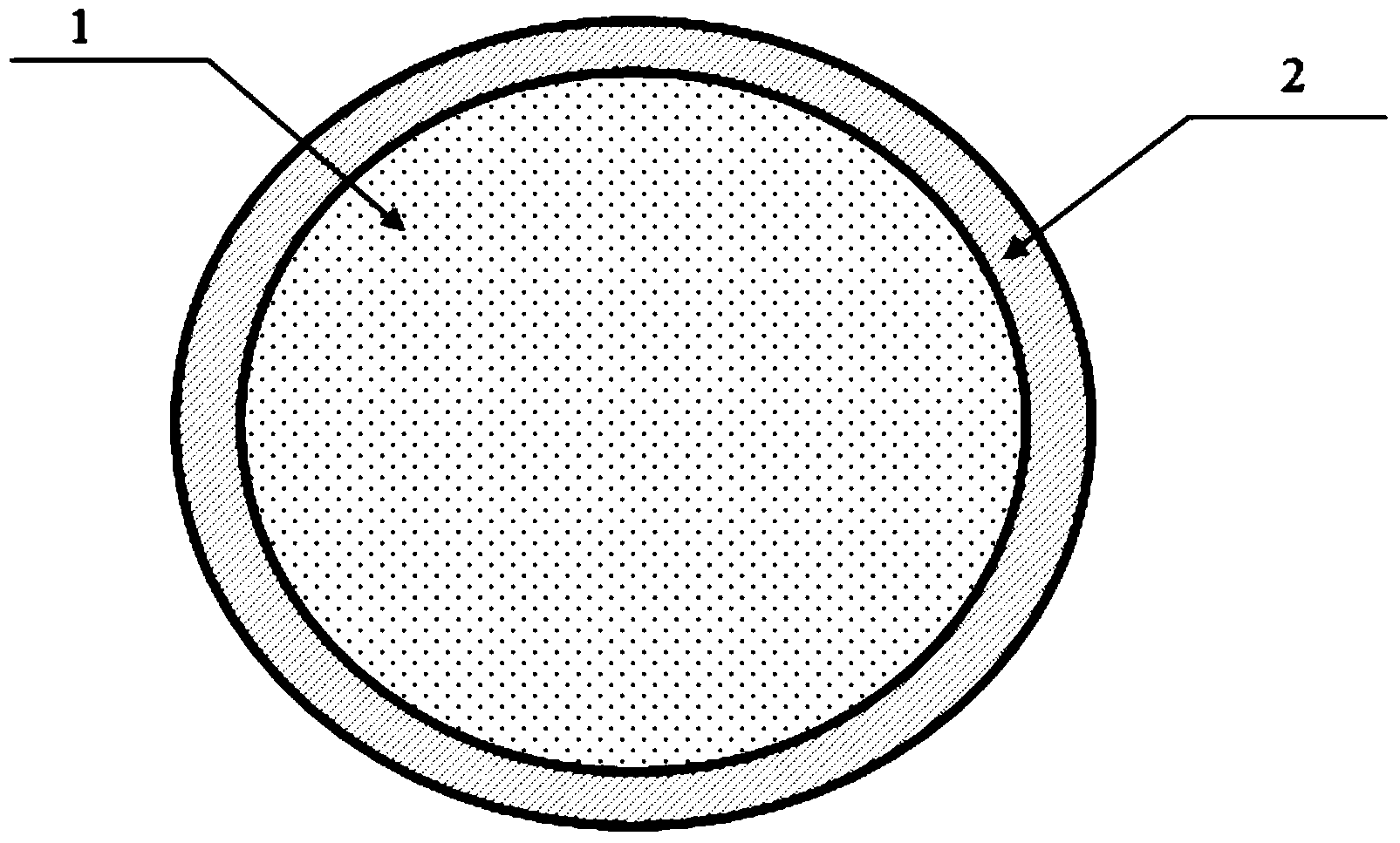

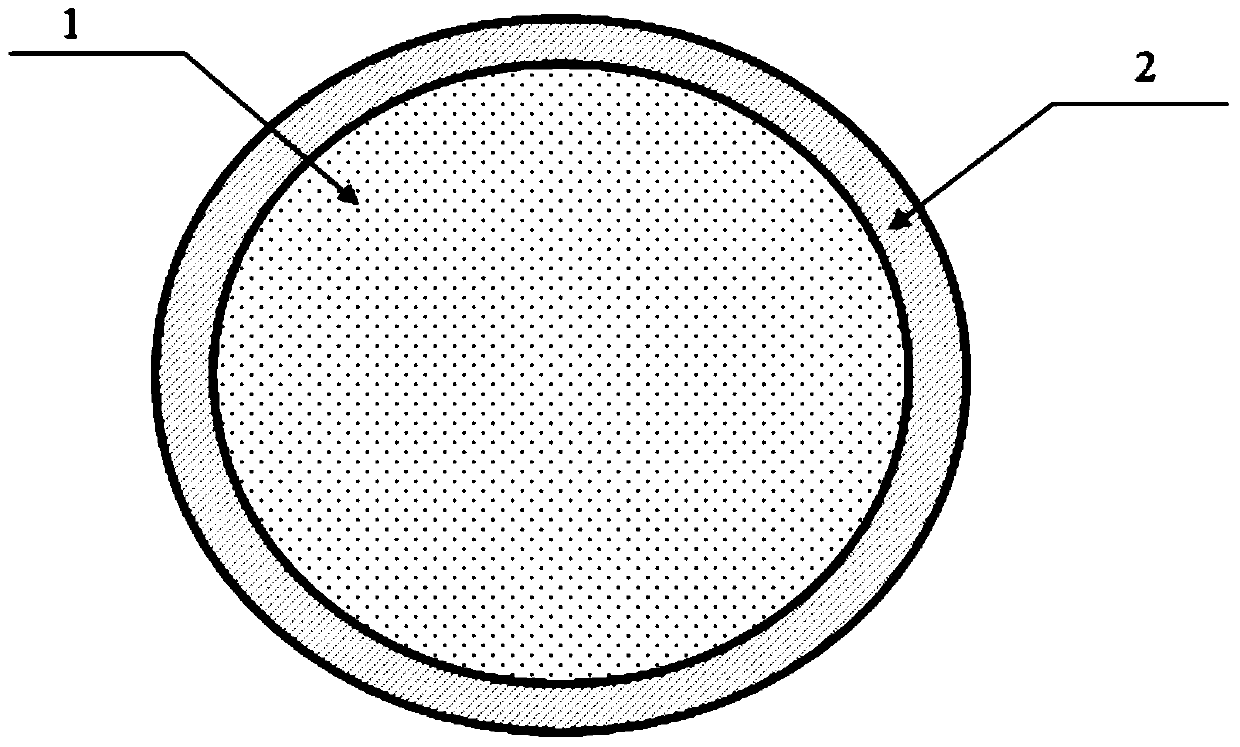

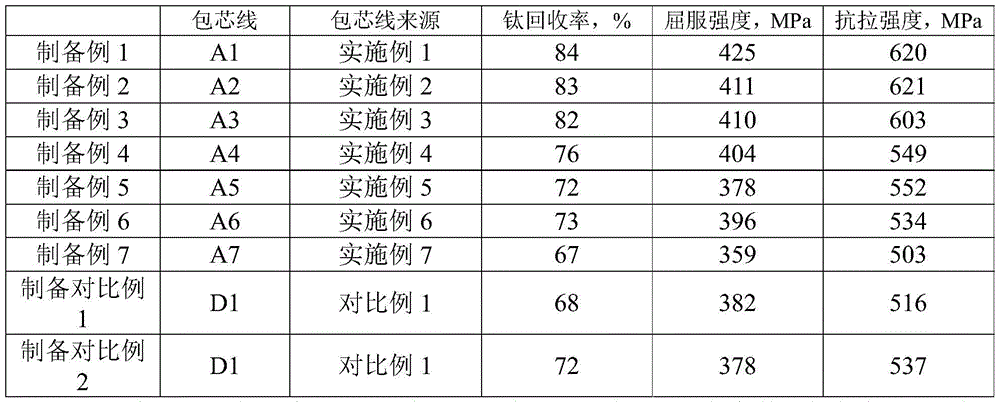

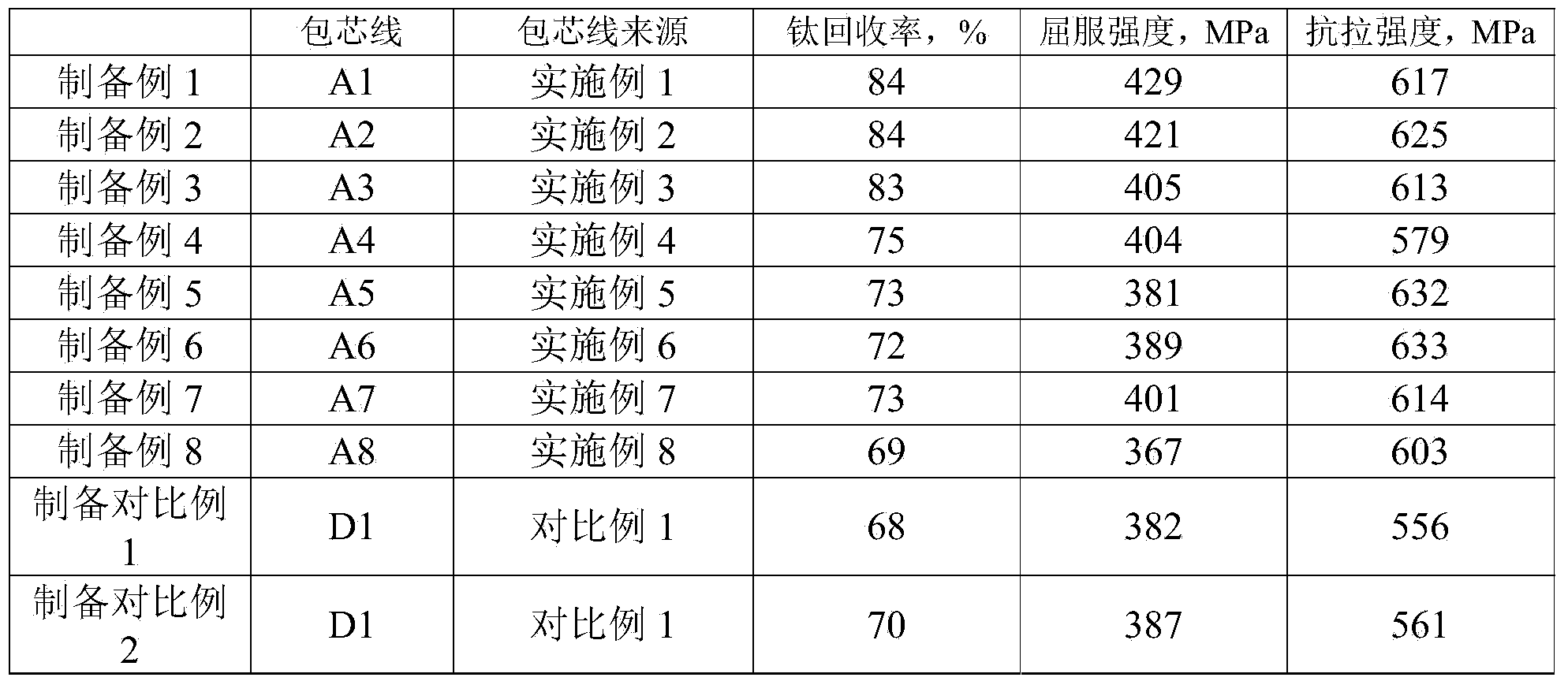

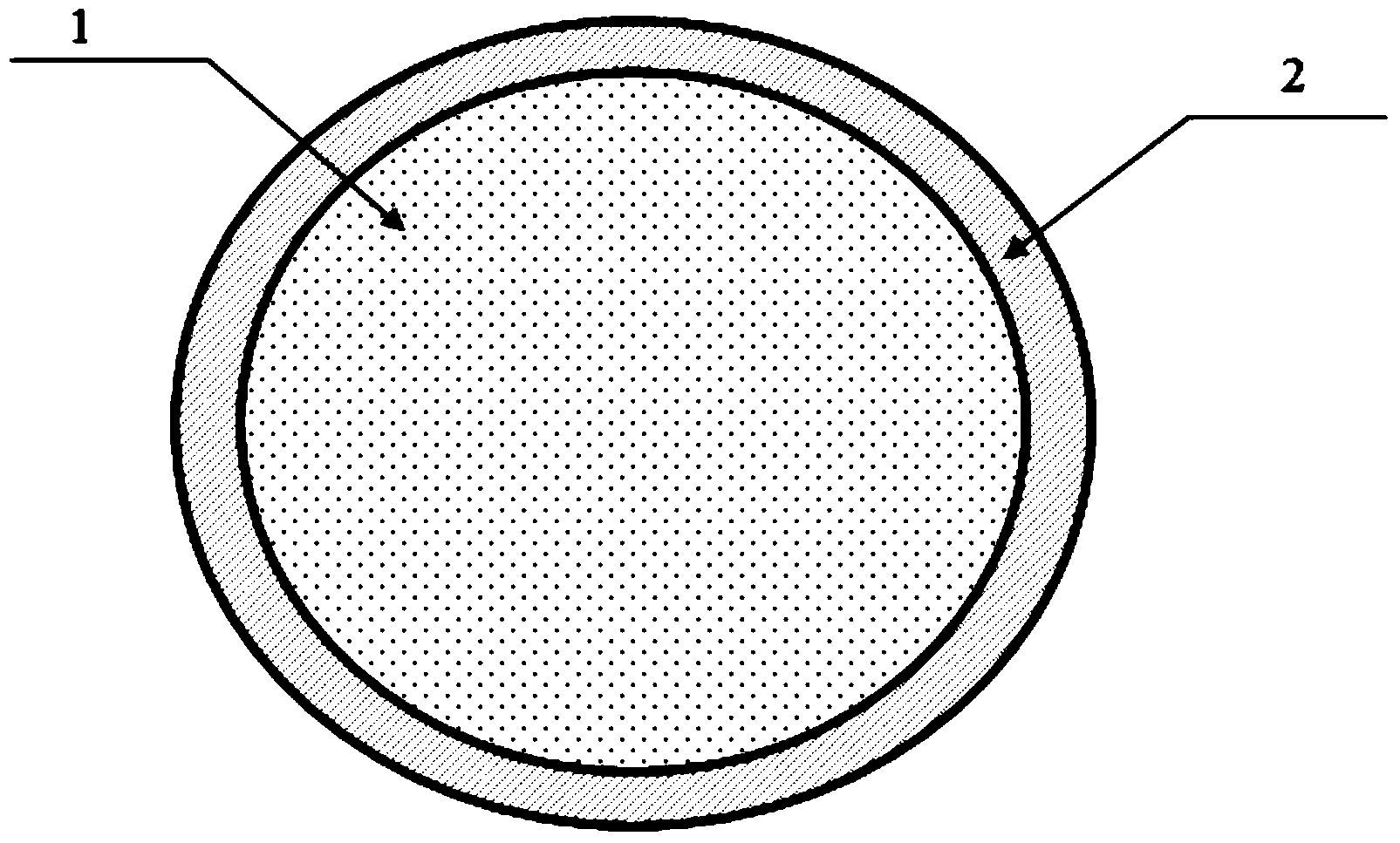

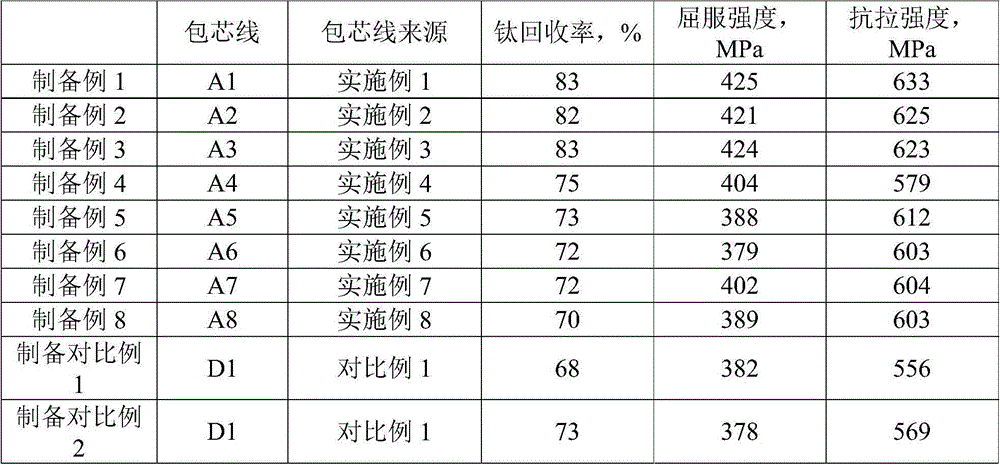

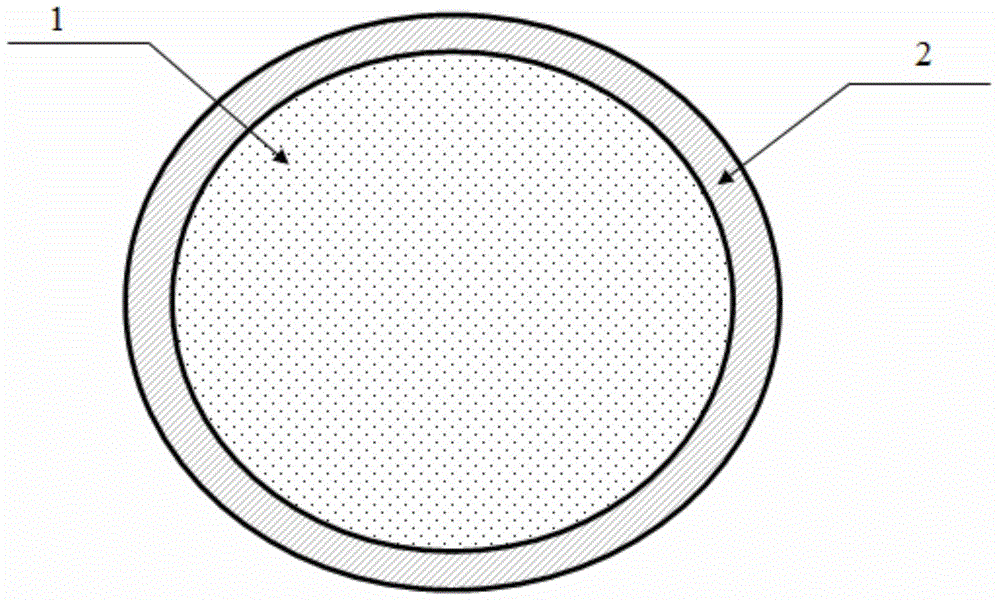

Titanium-aluminum core-spun yarn and application thereof, titanium alloying molten steel and preparation method thereof, and titanium-containing alloy steel

The invention provides a titanium-aluminum core-spun yarn which comprises a core layer and an aluminum sheath wrapped outside the core layer, wherein the core layer is titanium-iron powder. The invention provides application of the titanium-aluminum core-spun yarn in preparing titanium alloying molten steel. The invention provides a preparation method of the titanium alloying molten steel, which comprises the following steps: feeding the titanium-aluminum core-spun yarn into molten steel to be subjected to titanium alloying, and carrying out titanium alloying. The invention provides a titanium alloying molten steel prepared by the method. The invention provides a titanium-containing alloy steel which is prepared by casting the titanium alloying molten steel. In the preferable embodiment, the core-spun yarn is used for implementing titanium alloying of molten steel, and the titanium recovery rate is high and stable (80-85%), thereby effectively enhancing the quality of the molten steel.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

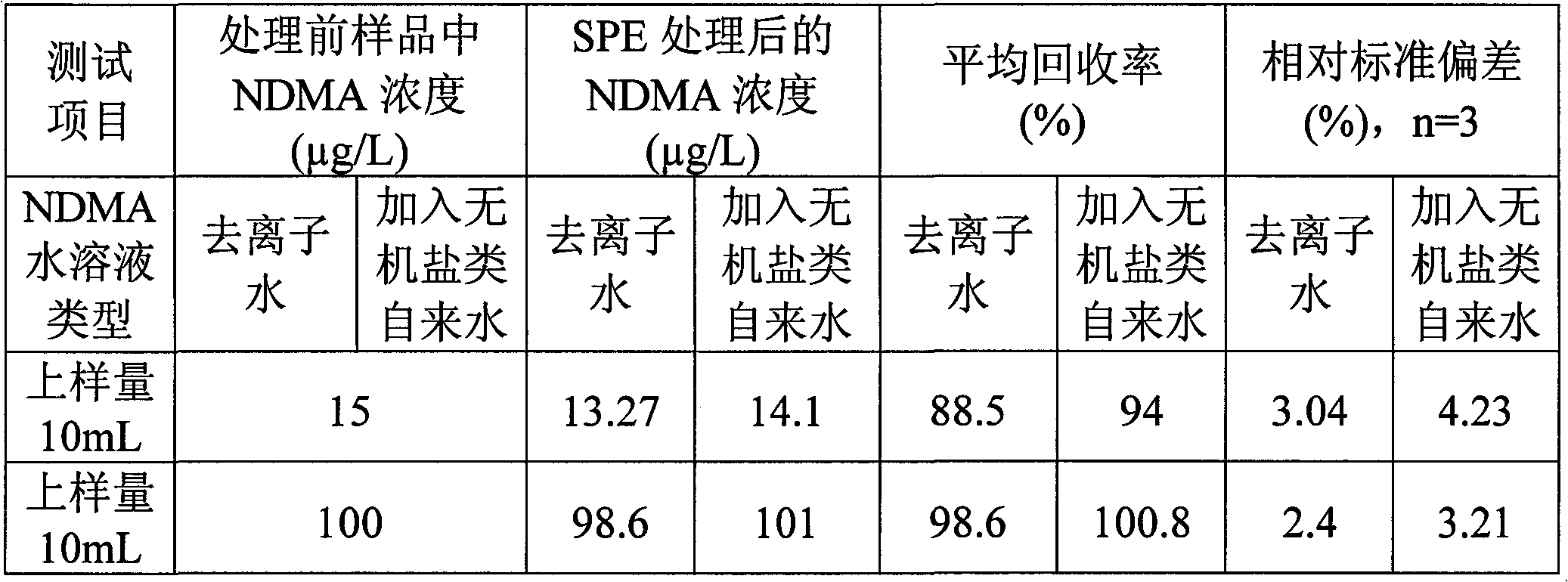

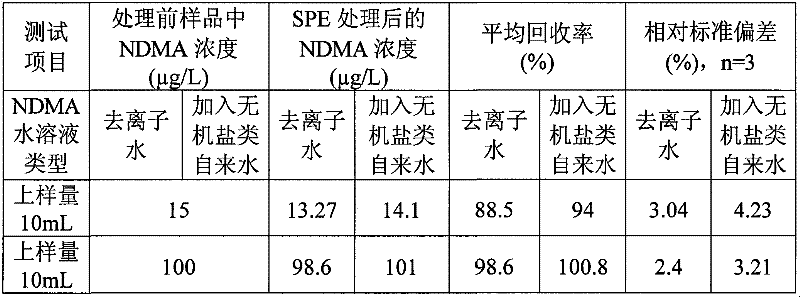

Solid phase extraction method of N-nitrosodimethylamine in water

InactiveCN101829437AEasy to manufactureLow costIon-exchange process apparatusOther chemical processesActivated carbonSolid phase extraction

The invention relates to a solid phase extraction method of N-nitrosodimethylamine in water. The method comprises preparing a solid phase extraction column and a using method of the solid phase extraction column. The prepared solid phase extraction (SPE) column is prepared by using 400 to 600 milligrams of active carbon with a particle size of 20 to 40 meshes and a specific surface area of 1,000 to 1,500m<2> / g, processing the active carbon, filling the active carbon, compressing the active carbon and sealing the active carbon for later use; and the using method comprises the processes of activation by methanol and deionized water, loading, leaching with normal hexane, and eluting with dichloromethane or methanol. The method of the invention has the advantages that: the SPE column can be manufactured simply and conveniently at low cost; and in use, the SPE column is high in yield, stable and environmentally-friendly and prevents interface emulsification effectively; and the adaptability of the SPE column is improved.

Owner:BEIJING UNIV OF TECH

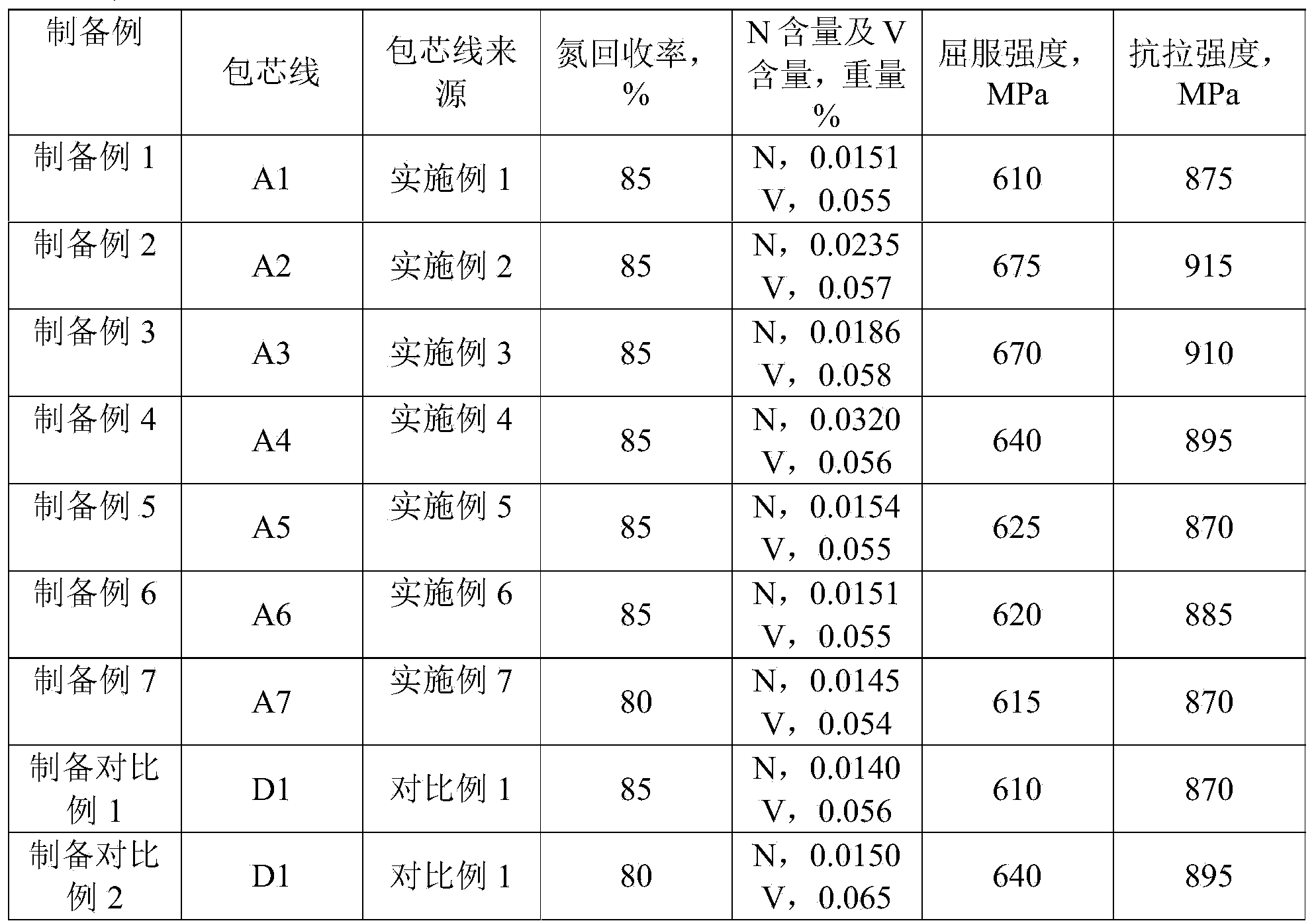

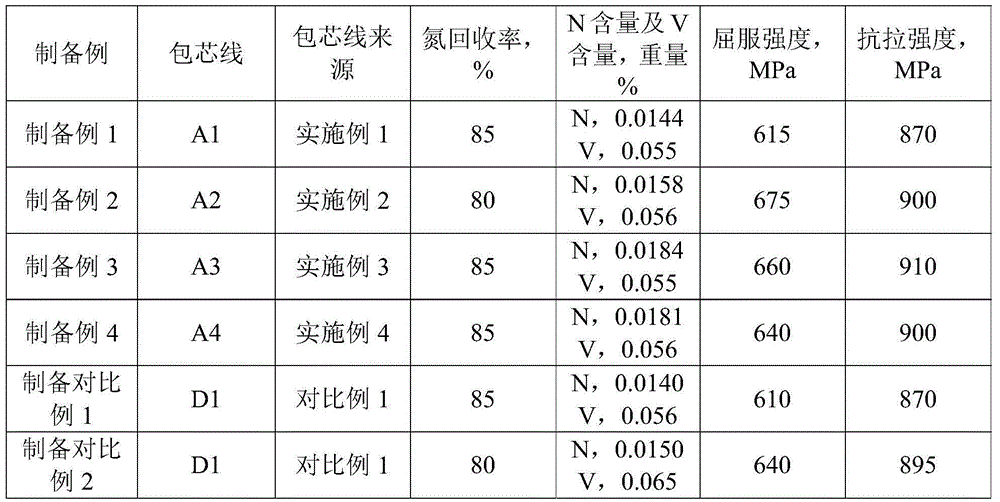

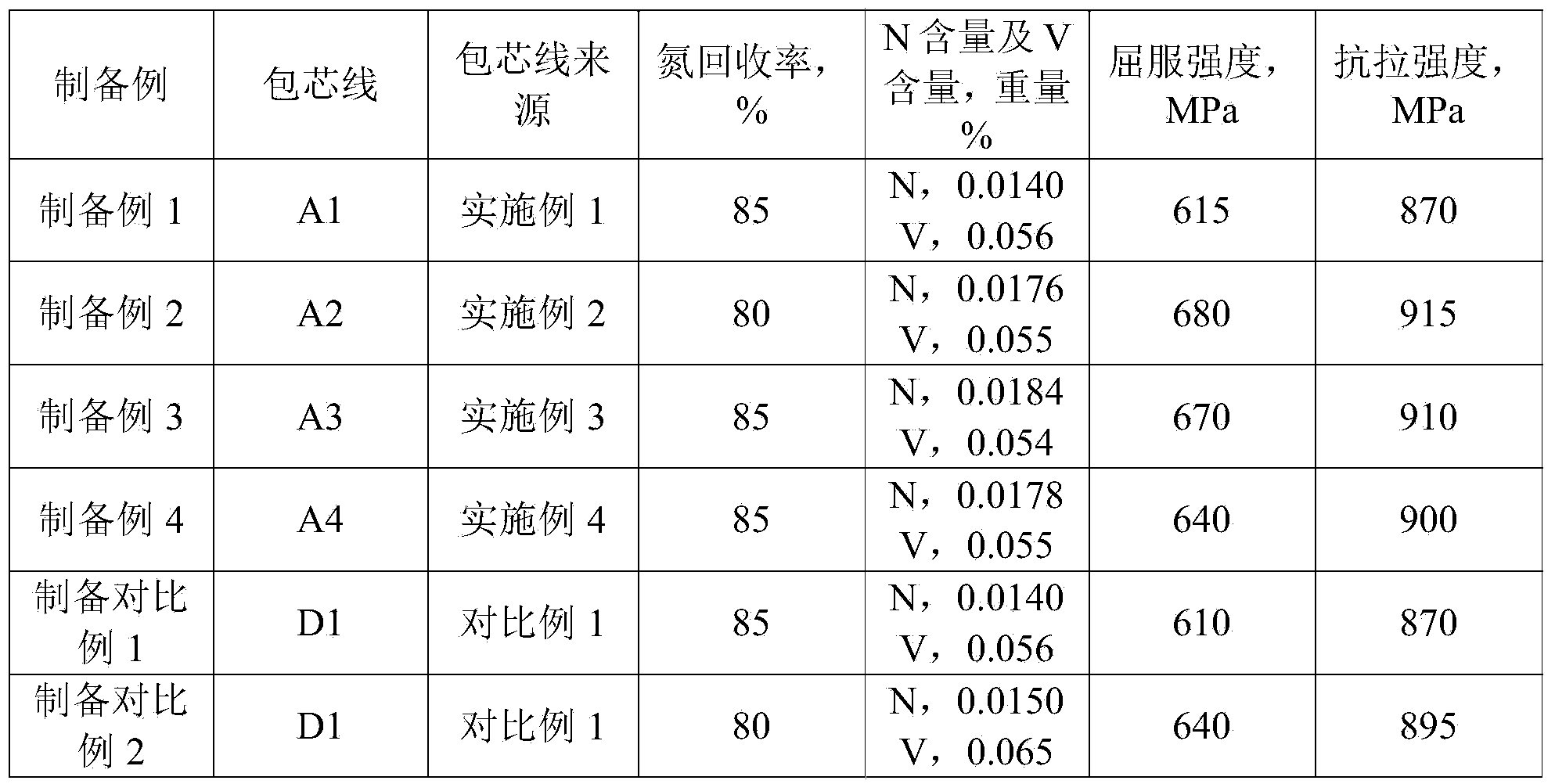

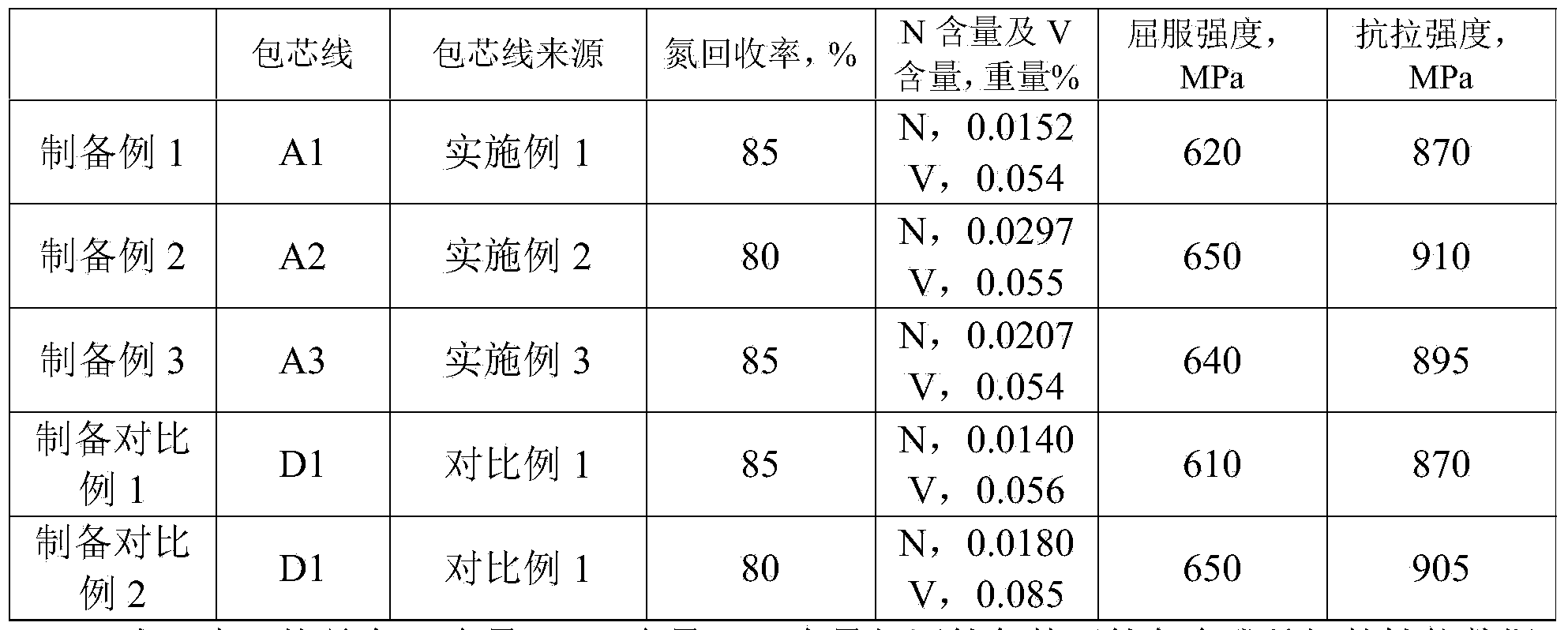

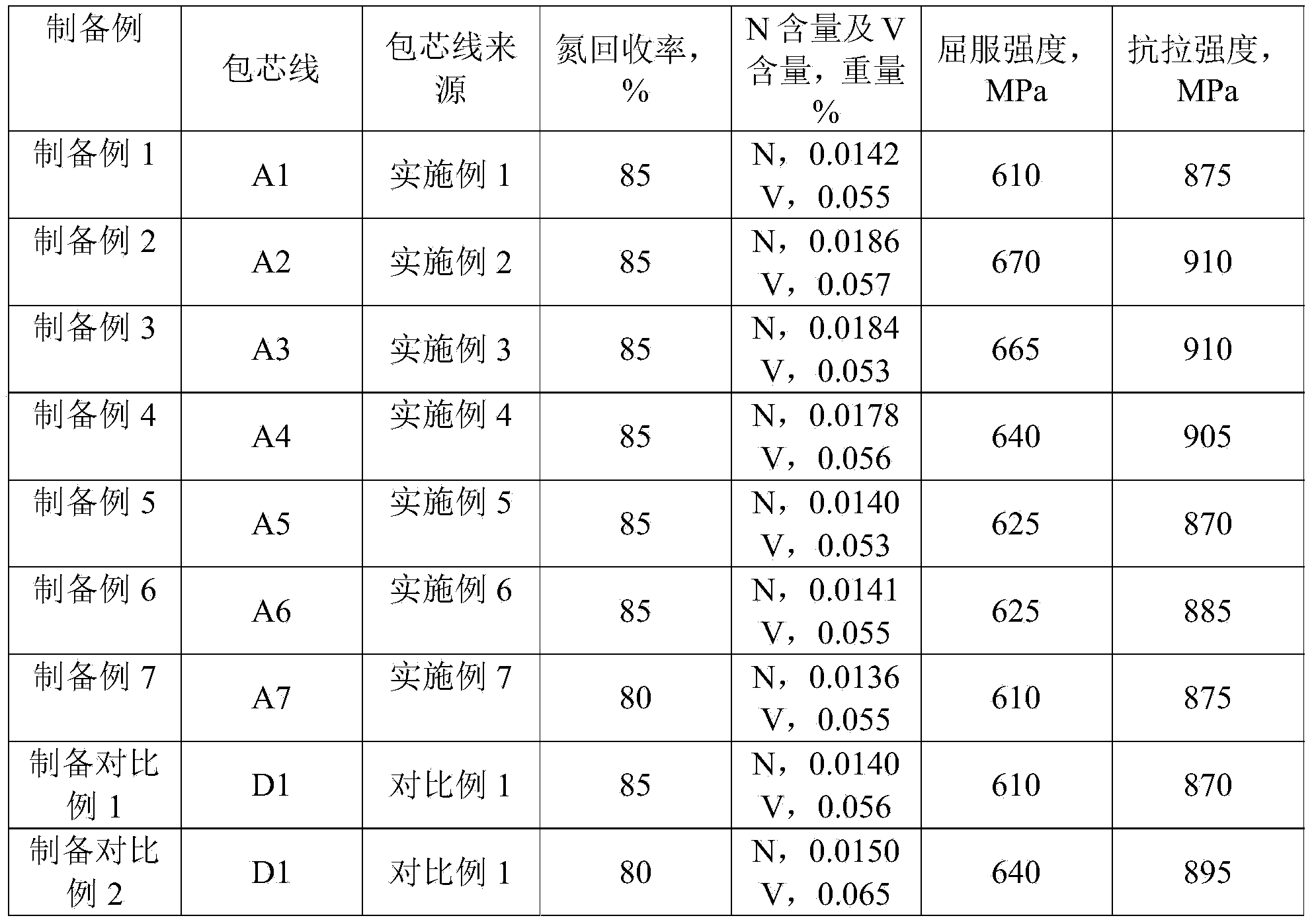

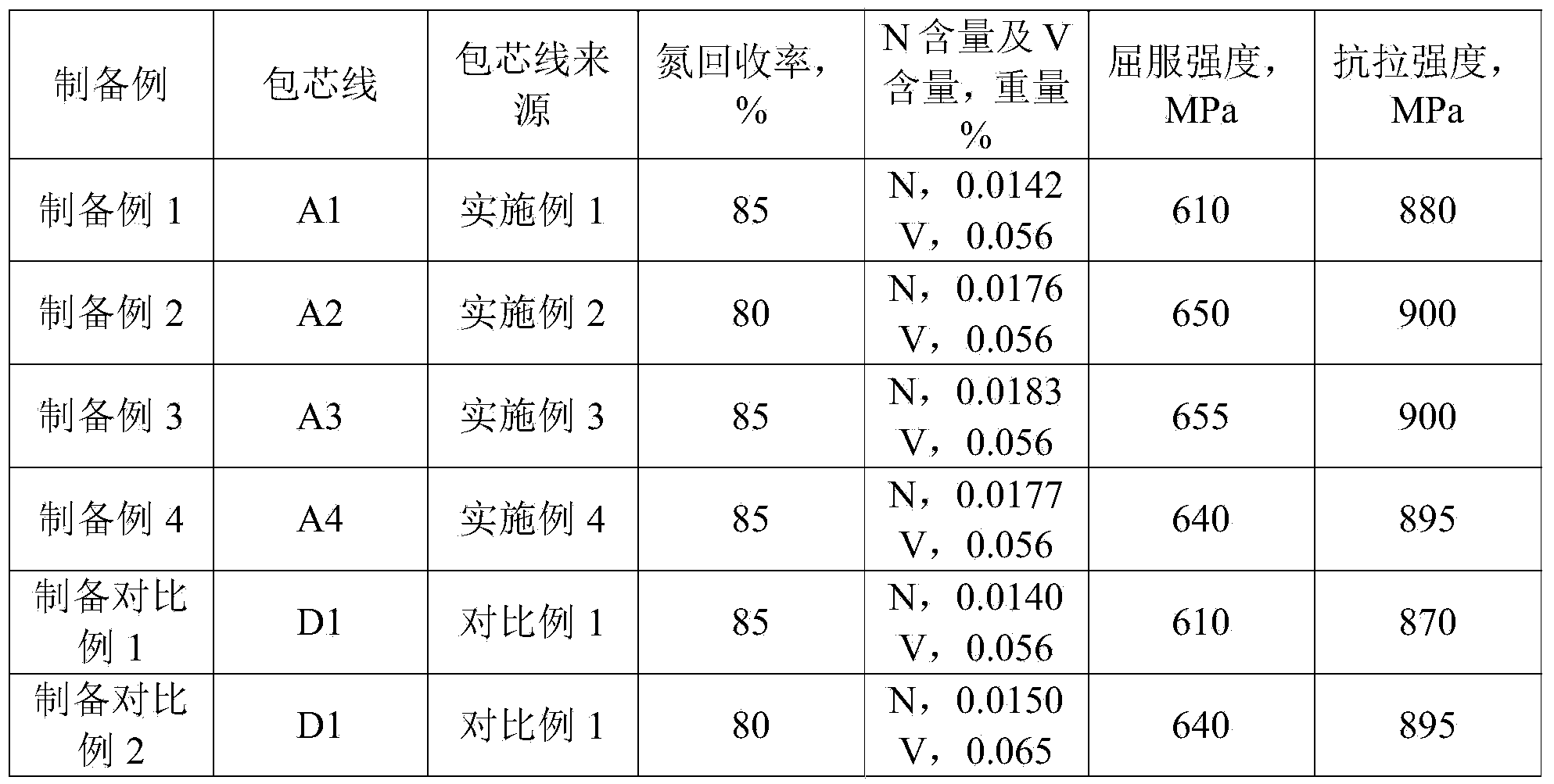

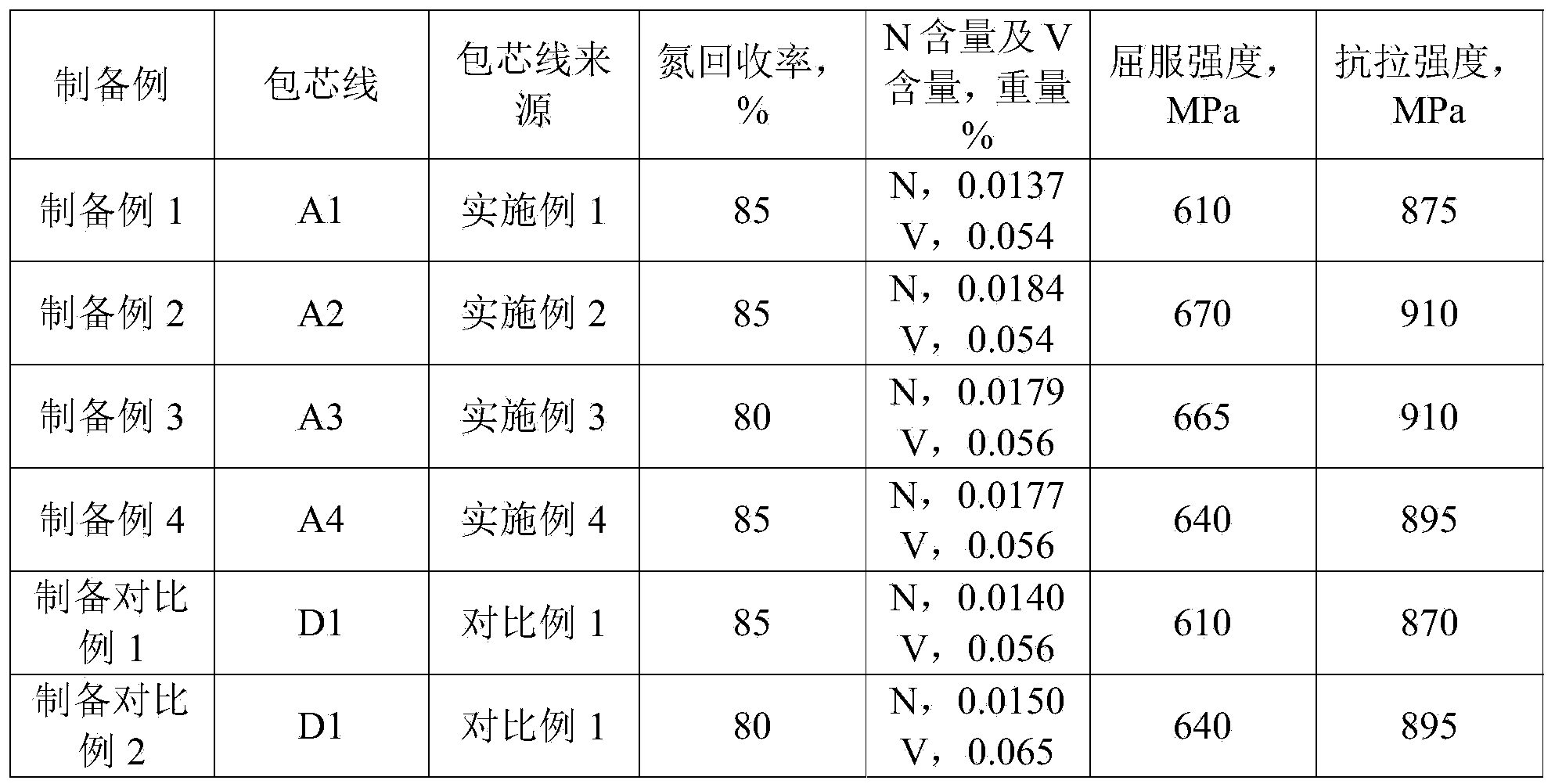

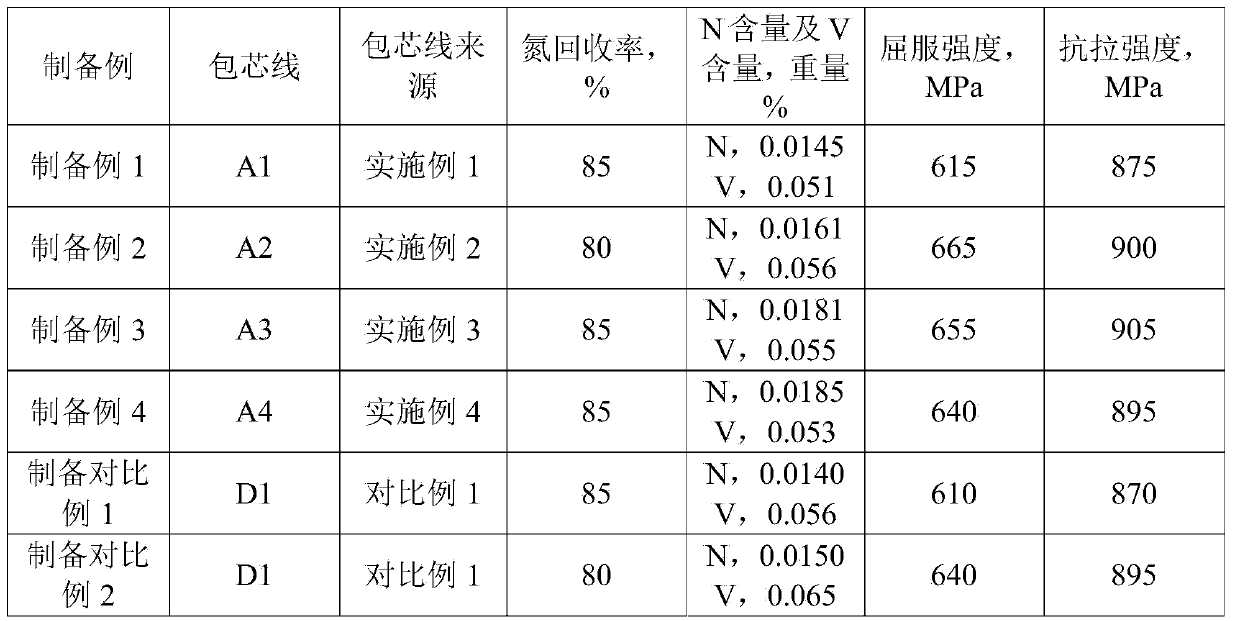

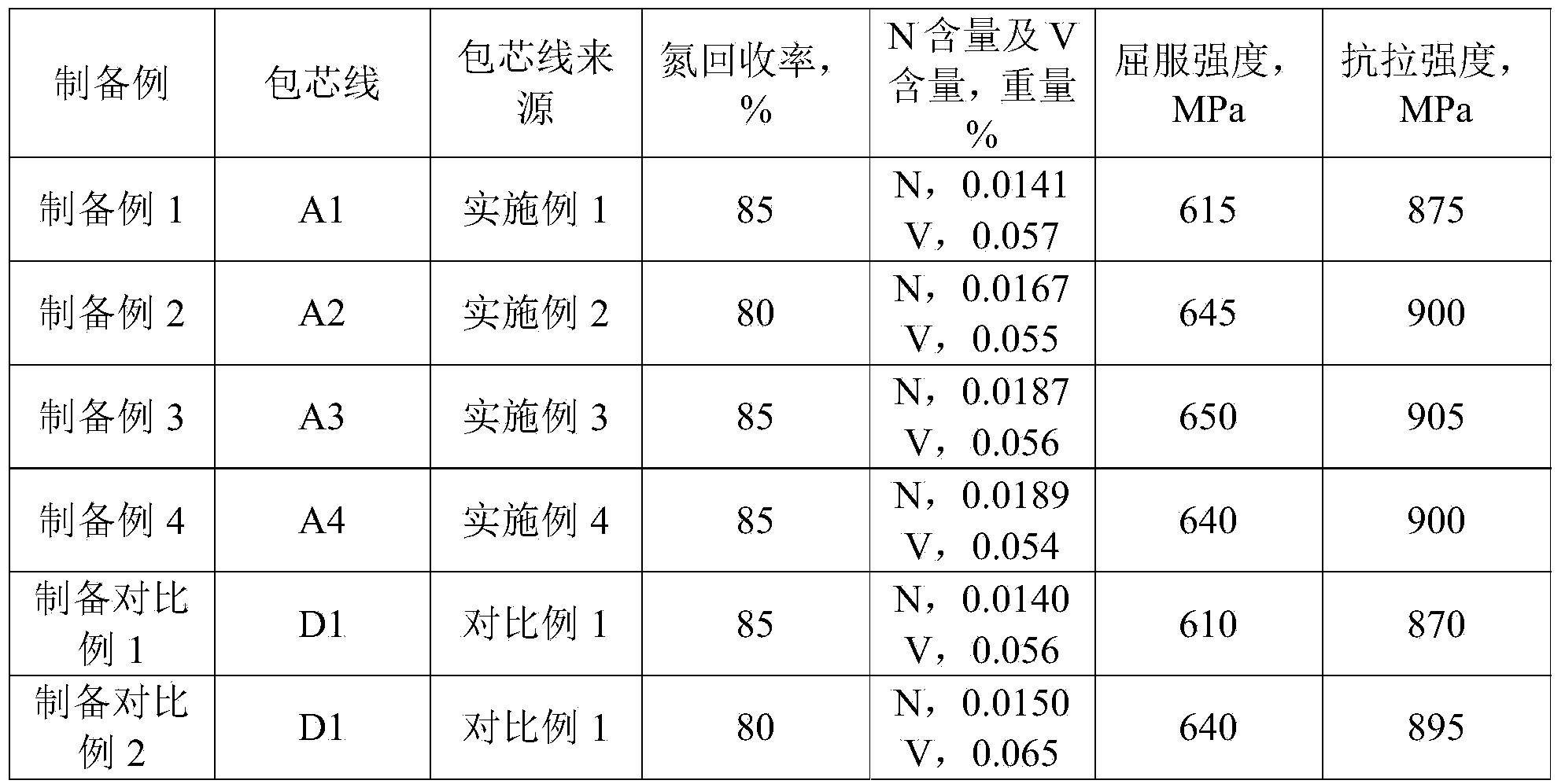

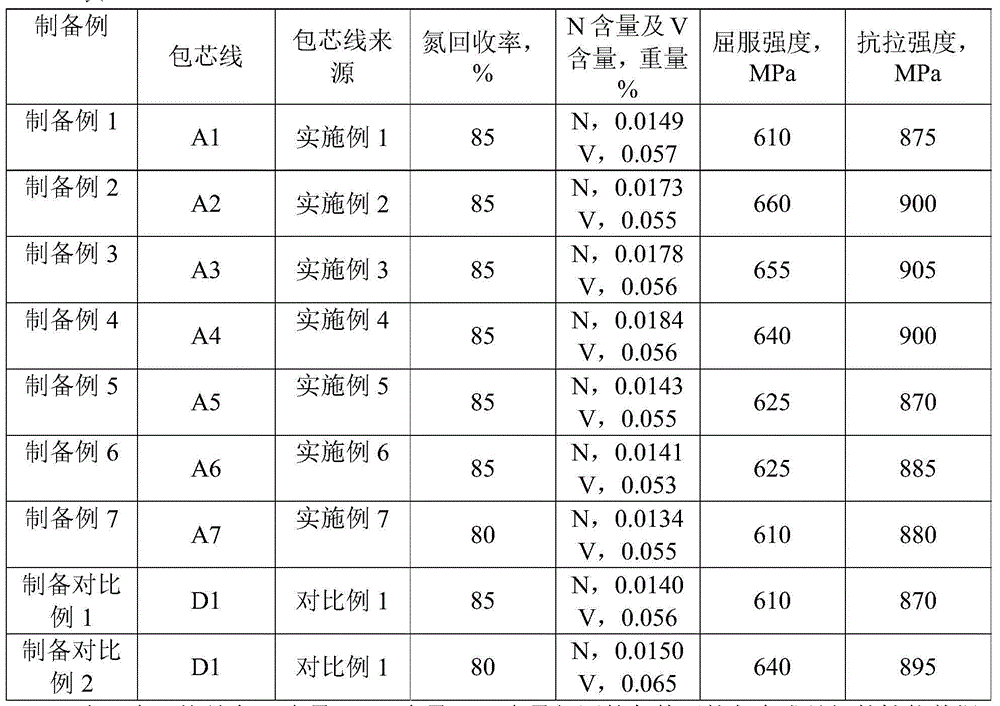

Cored wire, its application, vanadium and nitrogen alloyed molten steel, preparation method of vanadium and nitrogen alloyed molten steel, and vanadium and nitrogen micro-alloyed steel

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

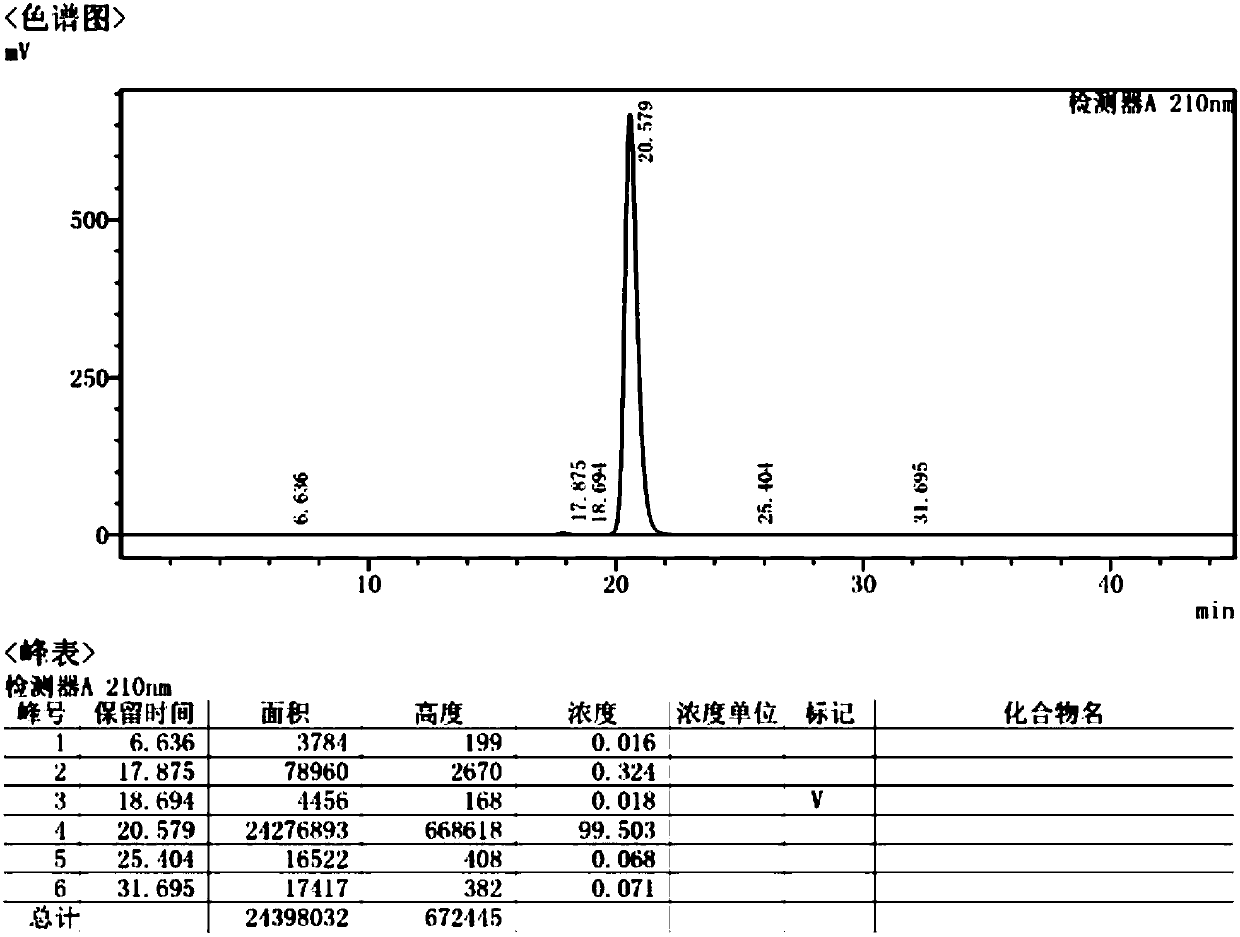

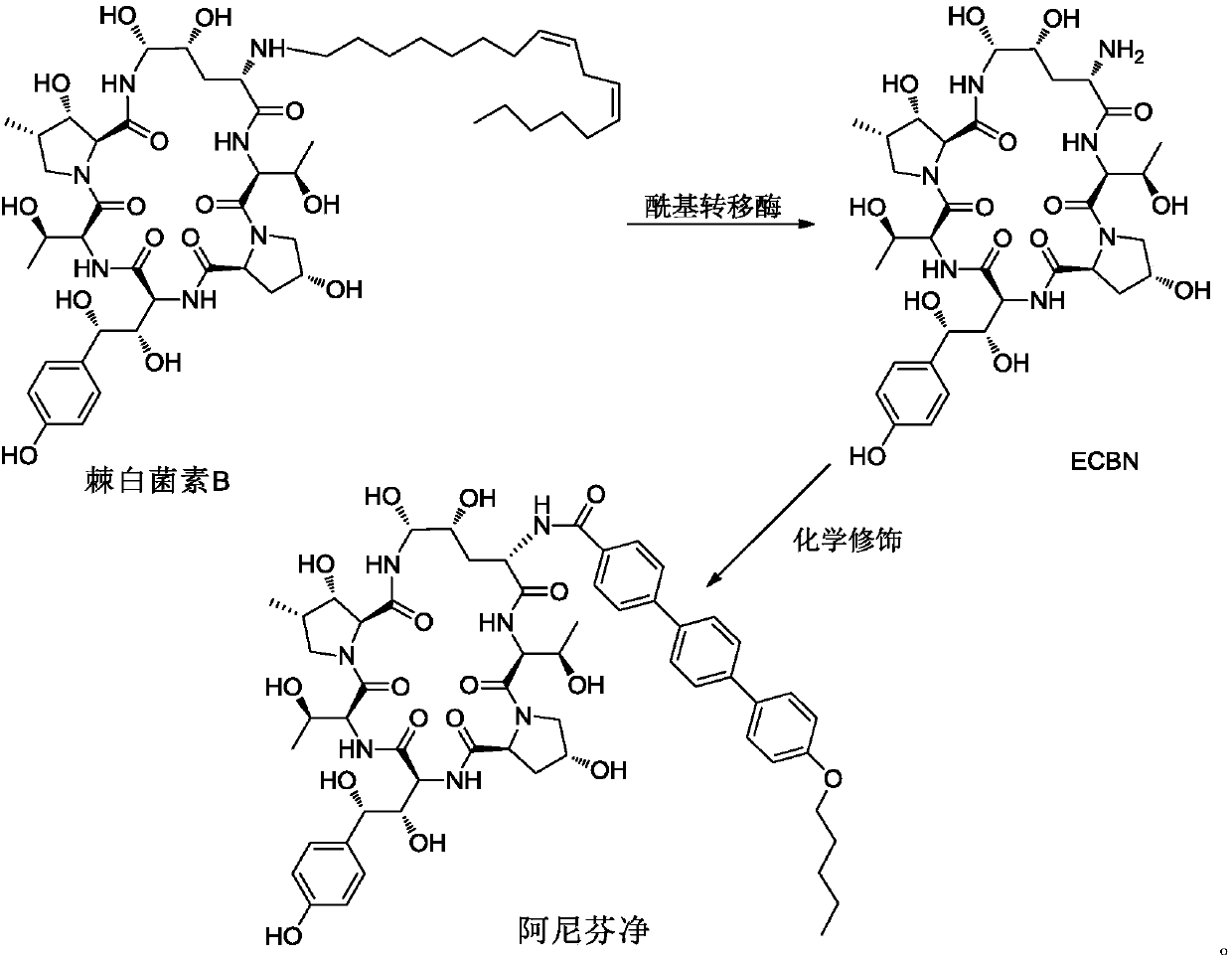

Purifying method for high-purity echinocandin B mother nucleus or salt thereof

InactiveCN107759668AHigh column efficiencyGood separation effectPeptide preparation methodsProduct recoveryChromatography column

The invention provides a purifying method for a high-purity echinocandin B mother nucleus or a salt thereof. The purifying method comprises the following steps: dissolving a crude product of an echinocandin B mother nucleus or a salt thereof to prepare a sample and loading the sample into a preparative high-performance liquid chromatographic column; carrying out elution with mixed liquor of an aqueous solution and an organic solvent as a mobile phase; and fractionally collecting eluates. The purifying method is simple to operate, high in purifying efficiency and easy in process flow; the recovery rate of the high-purity echinocandin B mother nucleus or the salt thereof is more than 85%; a small amount of organic solvents are used, so the method is friendly to environment; the method has good process reproducibility, can realize mass product, is high and stable in recovery rate and saves cost; product purity reaches 99% or above; the process of separation and purification is simple; andthe concentration of an organic phase is low, so elution time is short, and cost is saved.

Owner:JIANGSU SENRAN CHEM +1

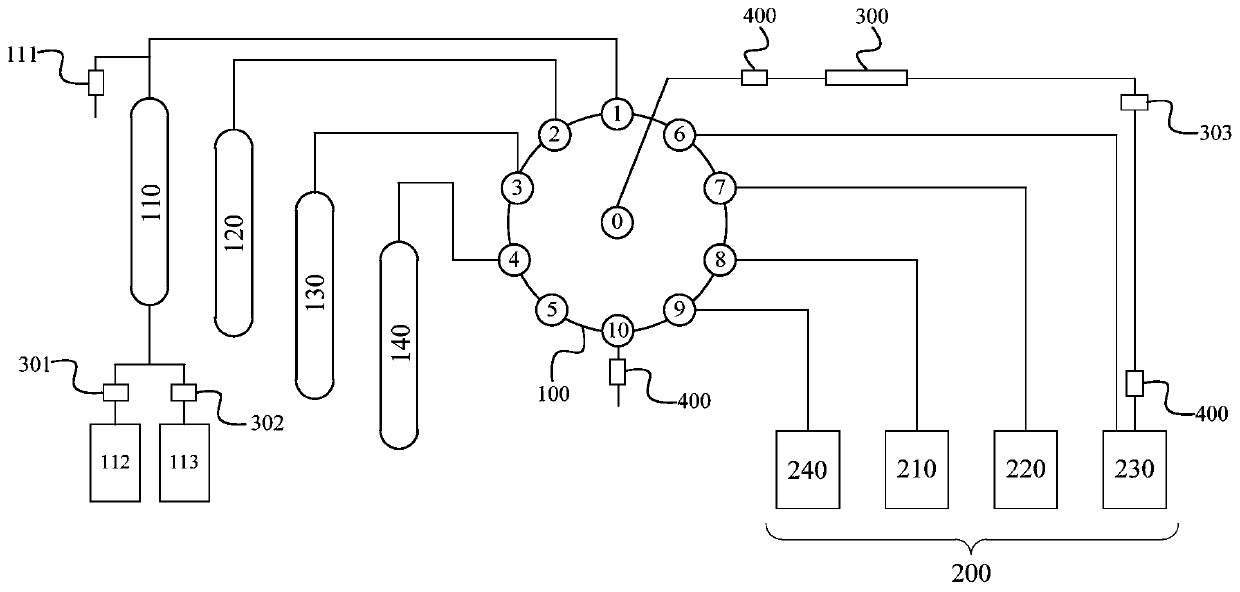

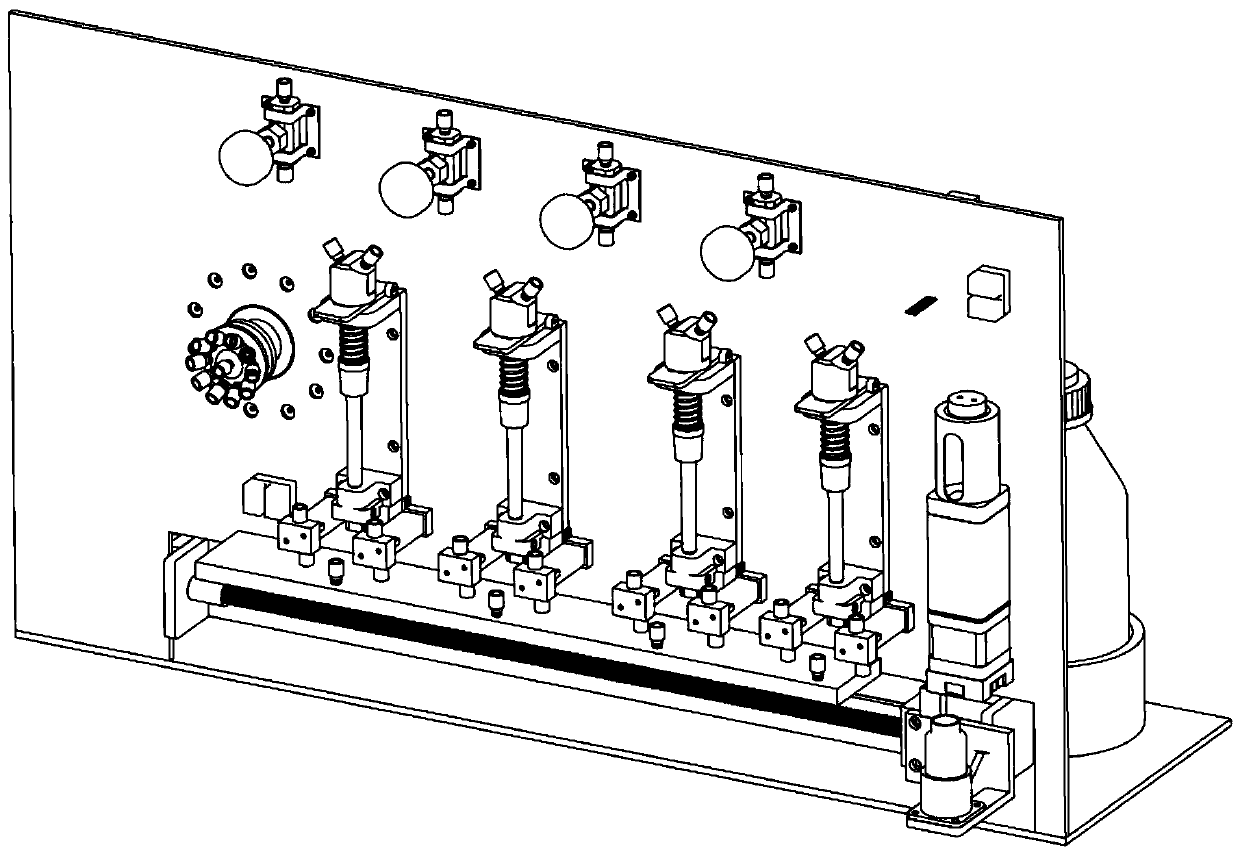

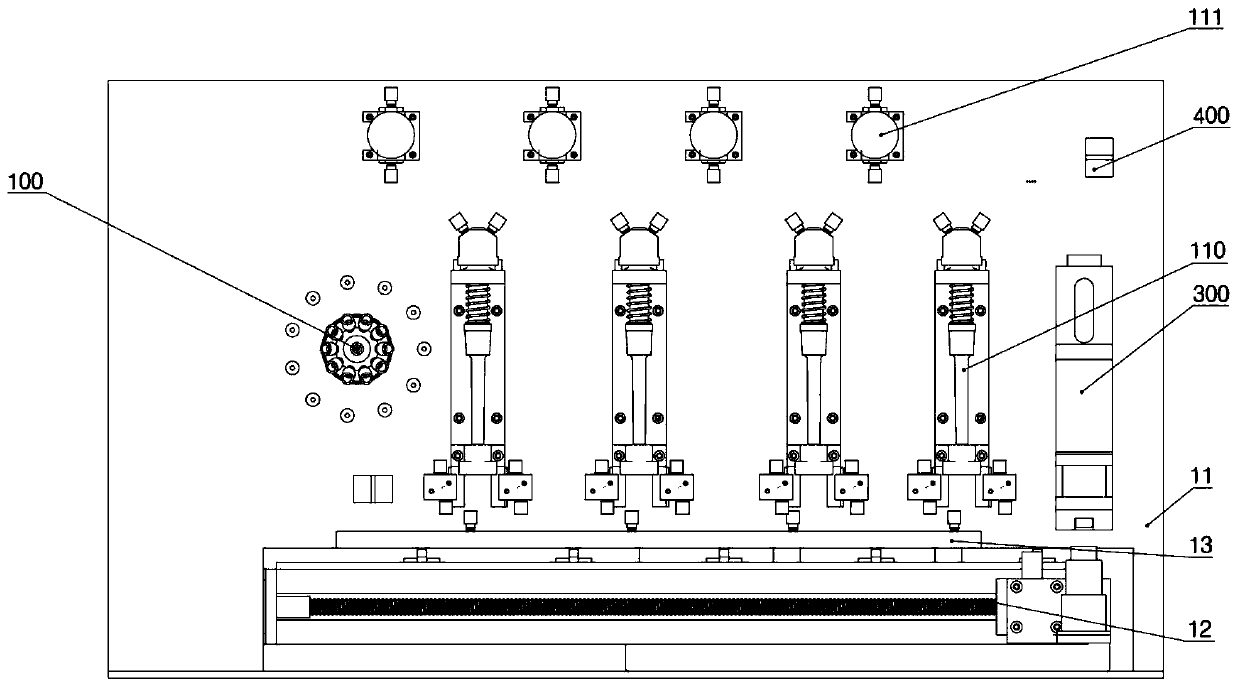

Automatic radiochemical separation device for strontium-90

ActiveCN110917658ARealization of automatic radiochemical separationHigh and stable recoveryPreparing sample for investigationSolid sorbent liquid separationPhysical chemistryEngineering

The invention discloses an automatic radiochemical separation device for strontium-90. The device comprises a plurality of crown ether extraction chromatographic columns, a plurality of liquid storagebottles, a multichannel switching valve and a reciprocating metering pump. The liquid storage bottles comprise at least one equilibrium liquid storage bottle, at least one leacheate storage bottle, at least one eluent storage bottle and at least one waste liquid storage bottle. The multichannel switching valve is provided with a main port, a sample injection branch port, a plurality of chromatographic column branch ports and a plurality of liquid storage bottle branch ports, each chromatographic column branch port is connected with one crown ether extraction chromatographic column, and each liquid storage bottle branch port is connected with one liquid storage bottle. One end of the reciprocating metering pump is connected with the main port. The device can realize automatic radiochemicalseparation of strontium-90, remarkably shortens the radiochemical separation time of a sample, and is high and stable in recovery rate of strontium-90.

Owner:TSINGHUA UNIV

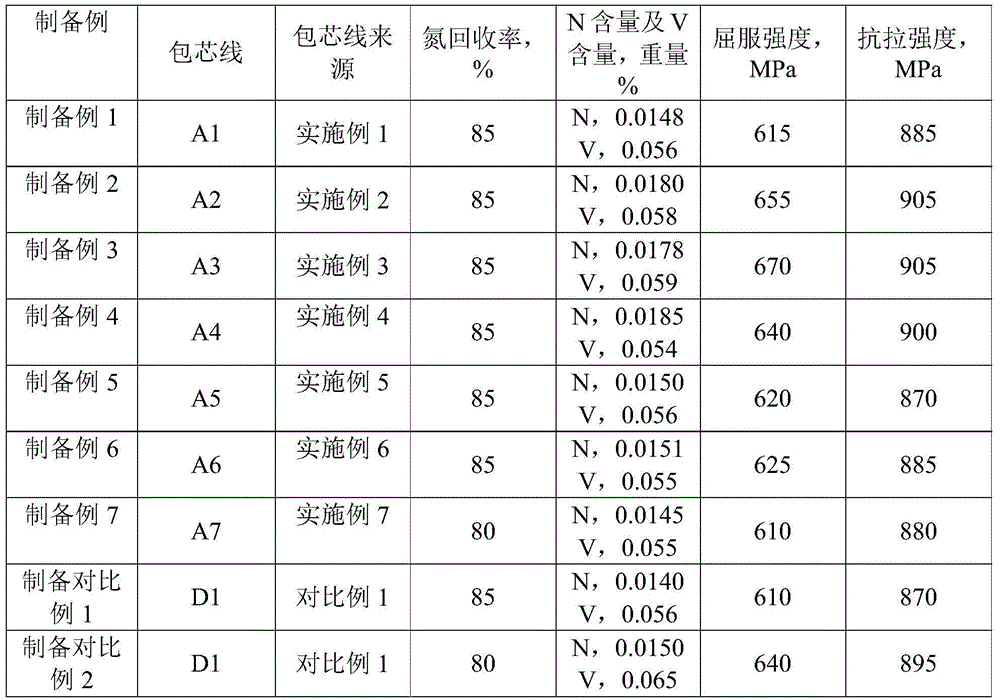

Core spun yarn and application thereof, vanadium nitrogen alloyed molten steel and preparation method thereof, and vanadium nitrogen microalloyed steel

The invention provides a core spun yarn and application thereof. The core spun yarn comprises a core layer and an outer layer wrapping the core layer, the core layer is a mixture comprising vanadium nitrogen alloy, ferro-silicon nitride, iron alloy and aluminum pills, and the iron alloy is titanium iron alloy and / or niobium iron alloy. The invention provides vanadium nitrogen alloyed molten steel and a preparation method thereof, and the method includes feeding of the core spun yarn into to-be-vanadium and nitrogen alloyed molten steel for vanadium nitrogen alloying. The invention provides vanadium nitrogen microalloyed steel, and the vanadium nitrogen microalloyed steel is casted by the vanadium nitrogen alloyed molten steel. The core spun yarn is used for realizing molten steel vanadium and nitrogen alloying, nitrogen content can be effectively increased without affecting on the vanadium content according to the need, vanadium containing steel with higher nitrogen content can be produced in the need of the molten steel, and the recovery rate of nitrogen is high and stable.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

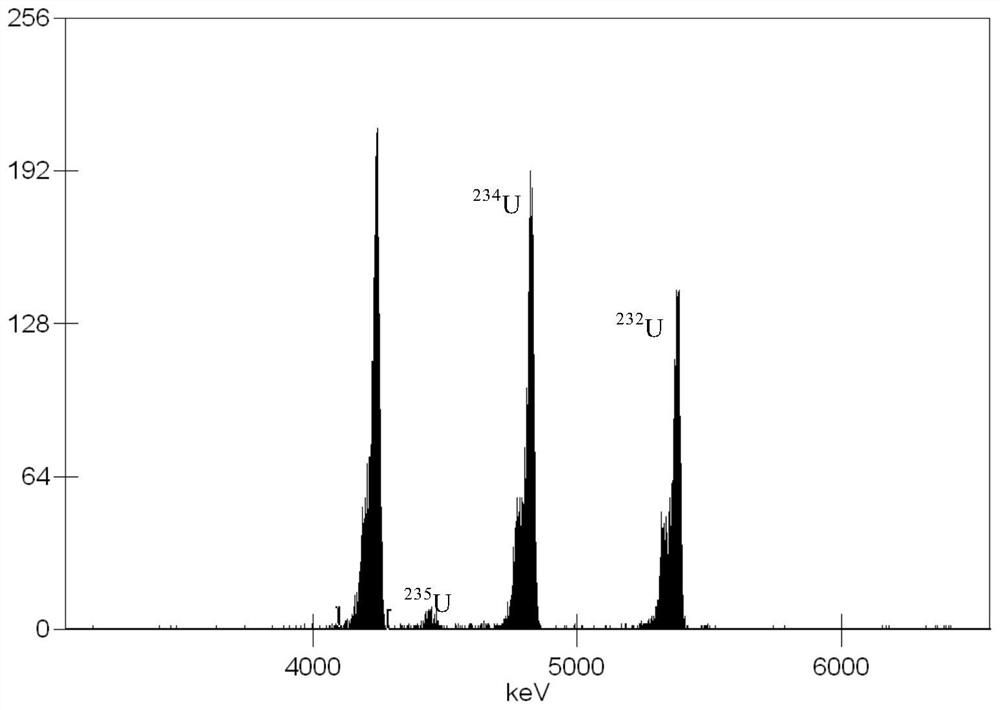

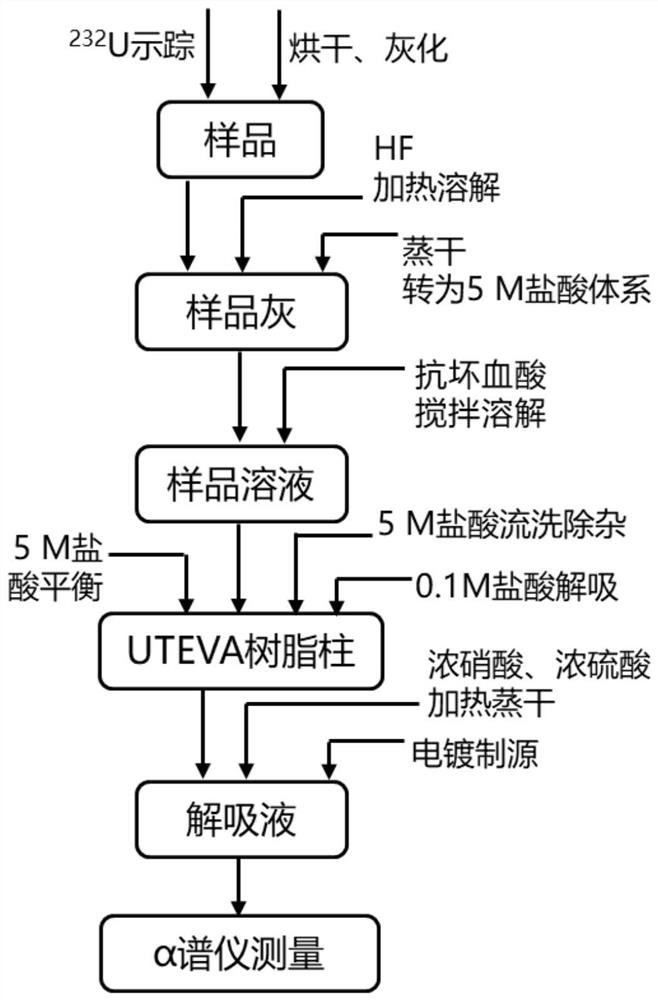

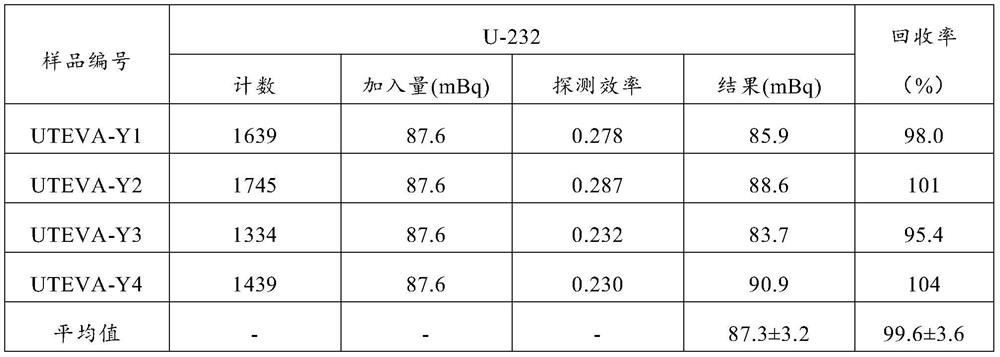

Method for analyzing uranium isotope content in aerosol by using UTEVA resin

ActiveCN113311468AGood application effectImprove accuracyNuclear energy generationX/gamma/cosmic radiation measurmentDistillationAshing

The invention belongs to the technical field of radiation environment monitoring, and relates to a method for analyzing uranium isotope content in aerosol by using UTEVA resin. The method comprises the following steps: (1) ashing; (2) transferring a system; (3) carrying out resin separation; (4) drying by distillation; and (5) measuring. According to the method for analyzing the uranium isotope content in the aerosol by using the UTEVA resin, the hydrochloric acid solution can be used as a separation and purification system, the analysis process is simplified, the applicability of the UTEVA resin is improved, and the accuracy and reliability of uranium isotope analysis results are improved.

Owner:CHINA INST FOR RADIATION PROTECTION

Titanium-calcium-silicon core-spun yarn and application thereof, titanium alloying molten steel and preparation method thereof, and titanium-containing alloy steel

The invention provides a titanium-calcium-silicon core-spun yarn which comprises a core layer and an outer layer wrapped outside the core layer, wherein the core layer contains titanium-iron powder and calcium-silicon powder. The invention provides application of the titanium-calcium-silicon core-spun yarn in preparing titanium alloying molten steel. The invention provides a preparation method of the titanium alloying molten steel, which comprises the following steps: feeding the titanium-calcium-silicon core-spun yarn into molten steel to be subjected to titanium alloying, and carrying out titanium alloying. The invention provides a titanium alloying molten steel prepared by the method. The invention provides a titanium-containing alloy steel which is prepared by casting the titanium alloying molten steel. In the preferable embodiment, the core-spun yarn is used for implementing titanium alloying of molten steel, and the titanium recovery rate is high and stable (80-85%), thereby effectively enhancing the quality of the molten steel.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Core spun yarn and application thereof, vanadium nitrogen alloyed molten steel and preparation method thereof, and vanadium nitrogen microalloyed steel

The invention provides a core spun yarn and application thereof. The core spun yarn comprises a core layer and an outer layer wrapping the core layer, and the core layer is a mixture comprising vanadium nitrogen alloy, ferro-silicon nitride, niobium iron alloy and aluminum pills. The invention provides vanadium nitrogen alloy molten steel and a preparation method thereof, and the method includes feeding of the core spun yarn into the to-be-vanadium and nitrogen alloyed molten steel for vanadium nitrogen alloying. The invention provides vanadium nitrogen microalloyed steel, and the vanadium nitrogen microalloyed steel is casted by the vanadium and nitrogen alloyed molten steel. The core spun yarn is used for realizing molten steel vanadium and nitrogen alloying, nitrogen content can be effectively increased without affecting the vanadium content according to the need, vanadium containing steel with higher nitrogen content can be produced in the need of the molten steel, and the recovery rate of nitrogen is high and stable. The vanadium nitrogen microalloyed steel casted by the vanadium and nitrogen alloyed molten steel produced by use of the core spun yarn for the molten steel vanadium and nitrogen alloying is high in yield strength and tensile strength.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Cored wire, its application, vanadium and nitrogen alloyed molten steel, preparation method of vanadium and nitrogen alloyed molten steel, and vanadium and nitrogen micro-alloyed steel

The invention provides a cored wire and its application. The cored wire comprises a core layer and an external layer wrapping the core layer, wherein the core layer is a mixture containing a vanadium-nitrogen alloy, manganese silicon nitride, a niobium-iron alloy and aluminum shots. The invention also provides a vanadium and nitrogen alloyed molten steel, and a preparation method thereof. The method comprises the steps of feeding the cored wire into molten steel to be vanadium and nitrogen alloyed, and carrying out vanadium and nitrogen alloying. The invention further provides a vanadium and nitrogen micro-alloyed steel. The vanadium and nitrogen micro-alloyed steel is obtained by casting the vanadium and nitrogen alloyed molten steel. The cored wire can be used for realizing the alloying of vanadium and nitrogen in molten steel, can effectively increase the oxygen content as needed without influencing the vanadium content, enables vanadium-containing steel with a higher content of nitrogen to be produced as needed, and can realize high and stable nitrogen recovery rate. The vanadium and nitrogen micro-alloyed steel obtained after casting the vanadium and nitrogen alloyed molten steel produced by carrying out molten steel vanadium and nitrogen alloying on the cored wire has high yield strength and tensile strength.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Titanium-calcium core-spun yarn and application thereof, titanium alloying molten steel and preparation method thereof, and titanium-containing alloy steel

The invention provides a titanium-magnesium core-spun yarn which comprises an inner sheath, an outer sheath, magnesium powder and titanium-iron powder, wherein the inner sheath is wrapped outside the titanium-iron powder, and the magnesium powder is filled between the inner sheath and the outer sheath. The invention provides application of the titanium-calcium core-spun yarn in preparing titanium alloying molten steel. The invention provides a preparation method of the titanium alloying molten steel, which comprises the following steps: feeding the titanium-magnesium core-spun yarn into molten steel to be subjected to titanium alloying, and carrying out titanium alloying. The invention provides a titanium alloying molten steel prepared by the method. The invention provides a titanium-containing alloy steel which is prepared by casting the titanium alloying molten steel. In the preferable embodiment, the core-spun yarn is used for implementing titanium alloying of molten steel, and the titanium recovery rate is high and stable (80-85%), thereby effectively enhancing the quality of the molten steel.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Cored wire, its application, vanadium and nitrogen alloyed molten steel, preparation method of vanadium and nitrogen alloyed molten steel, and vanadium and nitrogen micro-alloyed steel

The invention provides a cored wire and its application. The cored wire comprises a core layer and an external layer wrapping the core layer, wherein the core layer is powder containing a vanadium-nitrogen alloy and iron silicon nitride. The invention also provides a vanadium and nitrogen alloyed molten steel, and a preparation method thereof. The method comprises the steps of feeding the cored wire into molten steel to be vanadium and nitrogen alloyed, and carrying out vanadium and nitrogen alloying. The invention further provides a vanadium and nitrogen micro-alloyed steel. The vanadium and nitrogen micro-alloyed steel is obtained by casting the vanadium and nitrogen alloyed molten steel. The cored wire can be used for realizing the alloying of molten steel vanadium and nitrogen, can effectively increase the oxygen content as needed without influencing the vanadium content, enables vanadium-containing steel with a higher content of nitrogen to be produced as needed, and can realize high and stable nitrogen recovery rate. The vanadium and nitrogen micro-alloyed steel obtained after casting the vanadium and nitrogen alloyed molten steel produced by carrying out molten steel vanadium and nitrogen alloying on the cored wire has high yield strength and tensile strength.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Cored wire, its application, vanadium and nitrogen alloyed molten steel, preparation method of vanadium and nitrogen alloyed molten steel, and vanadium and nitrogen micro-alloyed steel

The invention provides a cored wire and its application. The cored wire comprises a core layer and an external layer wrapping the core layer, wherein the core layer is a mixture containing a vanadium-nitrogen alloy, manganese silicon nitride, an iron alloy and an iron-calcium alloy, and the iron alloy is a niobium-iron alloy and / or a titanium-iron alloy. The invention also provides a vanadium and nitrogen alloyed molten steel, and a preparation method thereof. The method comprises the steps of feeding the cored wire into molten steel to be vanadium and nitrogen alloyed, and carrying out vanadium and nitrogen alloying. The invention further provides a vanadium and nitrogen micro-alloyed steel. The vanadium and nitrogen micro-alloyed steel is obtained by casting the vanadium and nitrogen alloyed molten steel. The cored wire can be used for realizing the alloying of molten steel vanadium and nitrogen, can effectively increase the oxygen content as needed without influencing the vanadium content, enables vanadium-containing steel with a higher content of nitrogen to be produced as needed, and can realize high and stable nitrogen recovery rate.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Cored wire, its application, vanadium and nitrogen alloyed molten steel, preparation method of vanadium and nitrogen alloyed molten steel, and vanadium and nitrogen micro-alloyed steel

The invention provides a cored wire and its application. The cored wire comprises a core layer and an external layer wrapping the core layer, wherein the core layer is a mixture containing a vanadium-nitrogen alloy, manganese silicon nitride, a titanium-iron alloy and an iron-calcium alloy. The invention also provides a vanadium and nitrogen alloyed molten steel, and a preparation method thereof. The method comprises the steps of feeding the cored wire into molten steel to be vanadium and nitrogen alloyed, and carrying out vanadium and nitrogen alloying. The invention further provides a vanadium and nitrogen micro-alloyed steel. The vanadium and nitrogen micro-alloyed steel is obtained by casting the vanadium and nitrogen alloyed molten steel. The cored wire can be used for realizing the alloying of molten steel vanadium and nitrogen, can effectively increase the oxygen content as needed without influencing the vanadium content, enables vanadium-containing steel with a higher content of nitrogen to be produced as needed, and can realize high and stable nitrogen recovery rate.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Titanium-calcium-silicon cored wire and its application, titanium alloyed molten steel and its preparation method, and a titanium-containing alloy steel

The invention provides a titanium-calcium-silicon core-spun yarn which comprises a core layer and an outer layer wrapped outside the core layer, wherein the core layer contains titanium-iron powder and calcium-silicon powder. The invention provides application of the titanium-calcium-silicon core-spun yarn in preparing titanium alloying molten steel. The invention provides a preparation method of the titanium alloying molten steel, which comprises the following steps: feeding the titanium-calcium-silicon core-spun yarn into molten steel to be subjected to titanium alloying, and carrying out titanium alloying. The invention provides a titanium alloying molten steel prepared by the method. The invention provides a titanium-containing alloy steel which is prepared by casting the titanium alloying molten steel. In the preferable embodiment, the core-spun yarn is used for implementing titanium alloying of molten steel, and the titanium recovery rate is high and stable (80-85%), thereby effectively enhancing the quality of the molten steel.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Cored wire, its application, vanadium and nitrogen alloyed molten steel, preparation method of vanadium and nitrogen alloyed molten steel, and vanadium and nitrogen micro-alloyed steel

The invention provides a cored wire and its application. The cored wire comprises a core layer and an external layer wrapping the core layer, wherein the core layer is a mixture containing a vanadium-nitrogen alloy, manganese silicon nitride, an niobium-iron alloy and an aluminum-iron alloy. The invention also provides a vanadium and nitrogen alloyed molten steel, and a preparation method thereof. The method comprises the steps of feeding the cored wire into molten steel to be vanadium and nitrogen alloyed, and carrying out vanadium and nitrogen alloying. The invention further provides a vanadium and nitrogen micro-alloyed steel. The vanadium and nitrogen micro-alloyed steel is obtained by casting the vanadium and nitrogen alloyed molten steel. The cored wire can be used for realizing the alloying of vanadium and nitrogen in molten steel, can effectively increase the oxygen content as needed without influencing the vanadium content, enables vanadium-containing steel with a higher content of nitrogen to be produced as needed, and can realize high and stable nitrogen recovery rate.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Cored wire, its application, vanadium and nitrogen alloyed molten steel, preparation method of vanadium and nitrogen alloyed molten steel, and vanadium and nitrogen micro-alloyed steel

The invention provides a cored wire and its application. The cored wire comprises a core layer and an external layer wrapping the core layer, wherein the core layer is a mixture containing a vanadium-nitrogen alloy, iron silicon nitride, a titanium-iron alloy and aluminum shots. The invention also provides a vanadium and nitrogen alloyed molten steel, and a preparation method thereof. The method comprises the steps of feeding the cored wire into molten steel to be vanadium and nitrogen alloyed, and carrying out vanadium and nitrogen alloying. The invention further provides a vanadium and nitrogen micro-alloyed steel. The vanadium and nitrogen micro-alloyed steel is obtained by casting the vanadium and nitrogen alloyed molten steel. The cored wire can be used for realizing the alloying of molten steel vanadium and nitrogen, can effectively increase the oxygen content as needed without influencing the vanadium content, enables vanadium-containing steel with a higher content of nitrogen to be produced as needed, and can realize high and stable nitrogen recovery rate. The vanadium and nitrogen micro-alloyed steel obtained after casting the vanadium and nitrogen alloyed molten steel produced by carrying out molten steel vanadium and nitrogen alloying on the cored wire has high yield strength and tensile strength.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

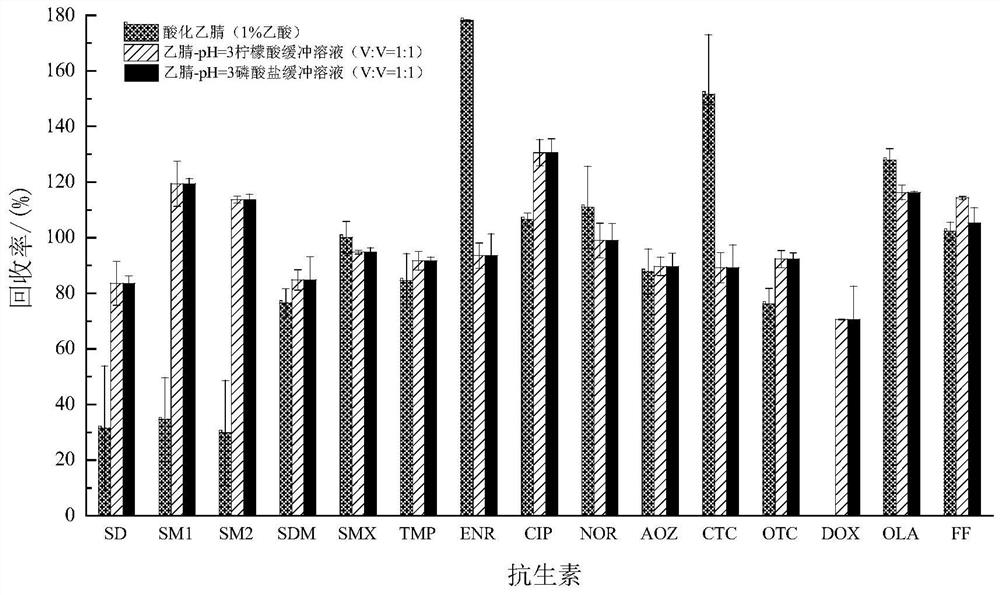

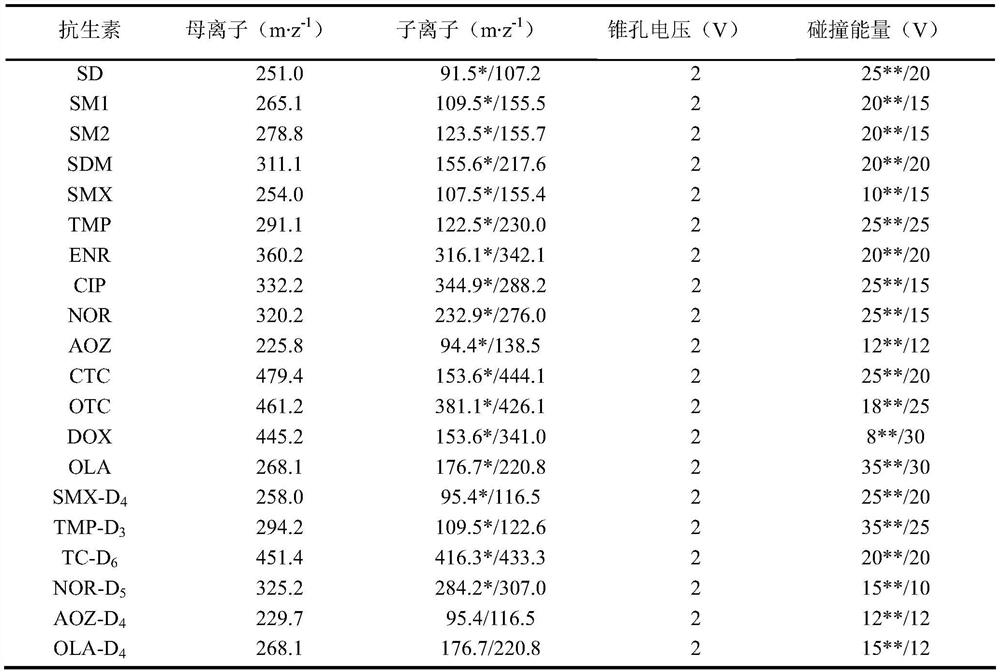

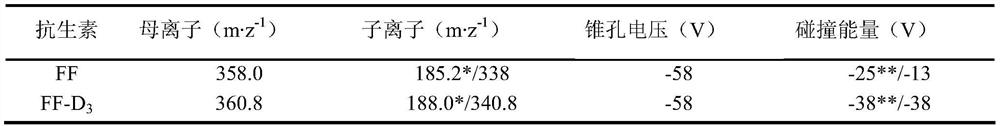

Method for detecting 15 antibiotics in fish body

PendingCN114720571AReduce dosageImprove extraction efficiencyComponent separationClimate change adaptationBiotechnologyFluid phase

The invention provides a method for detecting 15 antibiotics in a fish body, which comprises the following steps: sequentially adding an internal standard substance and an extraction solution into a fish meat sample, carrying out ultrasonic extraction, adding the obtained extraction solution into a solid-phase extraction column, enriching, eluting, degreasing, and determining the obtained sample solution by adopting ultra-high performance liquid chromatography-tandem mass spectrometry, 15 antibiotics in the sample solution are determined according to the retention time, an internal standard curve method is adopted for quantification, and the content of the 15 antibiotics in the sample solution is determined. According to the method for detecting the 15 antibiotics in the fish body, provided by the invention, 7 types of 15 antibiotics in fish meat can be rapidly, efficiently, sensitively and accurately detected at the same time, the detection efficiency is greatly improved, and the method has the advantages of high recovery rate, high sensitivity, high stability, low detection limit, more real and reliable detection result and the like.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

Method for recovering germanium from zinc dross

ActiveCN101760653BNo pollution in the processSolve the technical problems of recyclingProcess efficiency improvementIndiumEvaporation

Then invention relates to a method for recovering germanium from zinc dross, belonging to the technical field of non-ferrous metallurgy. After the secondary extracted zinc is leached by adopting the wet method, and the leached dross can be pre-treated, the germanium can be converted into the germanic from the low-valence in metal or germanium monoxide. Namely, hydrogen peroxide is used for oxidizing germanium, lead, indium, arsenic and other elements in the hydrochloric acid medium, so that the elements can be oxidized from low valence to high valence; the lead, indium, arsenic, gallium and the like react into solution, the low-valence germanium wrapped by the elements can be exposed and oxidized to be the germanic by the hydrogen peroxide under the acid condition into hydrochloric acid solution, and the germanic can escape in a form of germanium tetrachloride by evaporation, so as to realize the separation with other purities; and then, the separated germanium tetrachloride is purified and hydrolyzed, so as to prepare germanium dioxide. In the zinc dross with the germanic being more than 2.0%, the recovery rate of the germanic can reach more than 98%; in the zinc dross with the germanic being more than 1.0-2.0%, the recovery rate of the germanic can reach more than 95%; and in the zinc dross with the germanic being 0.1-1.0%, the recovery rate of the germanic can reach more than 90%.

Owner:YUNNAN WUXIN IND

Solid phase extraction method of N-nitrosodimethylamine in water

InactiveCN101829437BEasy to manufactureLow costIon-exchange process apparatusOther chemical processesActivated carbonSolid phase extraction

The invention relates to a solid phase extraction method of N-nitrosodimethylamine in water. The method comprises preparing a solid phase extraction column and a using method of the solid phase extraction column. The prepared solid phase extraction (SPE) column is prepared by using 400 to 600 milligrams of active carbon with a particle size of 20 to 40 meshes and a specific surface area of 1,000 to 1,500m<2> / g, processing the active carbon, filling the active carbon, compressing the active carbon and sealing the active carbon for later use; and the using method comprises the processes of activation by methanol and deionized water, loading, leaching with normal hexane, and eluting with dichloromethane or methanol. The method of the invention has the advantages that: the SPE column can be manufactured simply and conveniently at low cost; and in use, the SPE column is high in yield, stable and environmentally-friendly and prevents interface emulsification effectively; and the adaptability of the SPE column is improved.

Owner:BEIJING UNIV OF TECH

Titanium-aluminum cored wire and its application, titanium alloyed molten steel and its preparation method, and a titanium-containing alloy steel

Owner:SICHUAN PAN YAN TECH

Titanium-magnesium composite core-spun yarn and application thereof, titanium alloying molten steel and preparation method thereof, and titanium-containing alloy steel

The invention provides a titanium-magnesium composite core-spun yarn which comprises a core layer and an outer layer wrapped outside the core layer, wherein the core layer contains titanium-iron powder and magnesium powder. The invention provides application of the titanium-magnesium composite core-spun yarn in preparing titanium alloying molten steel. The invention provides a preparation method of the titanium alloying molten steel, which comprises the following steps: feeding the titanium-magnesium composite core-spun yarn into molten steel to be subjected to titanium alloying, and carrying out titanium alloying. The invention provides a titanium alloying molten steel prepared by the method. The invention provides a titanium-containing alloy steel which is prepared by casting the titanium alloying molten steel. In the preferable embodiment, the core-spun yarn is used for implementing titanium alloying of molten steel, and the titanium recovery rate is high and stable (80-85%), thereby effectively enhancing the quality of the molten steel.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

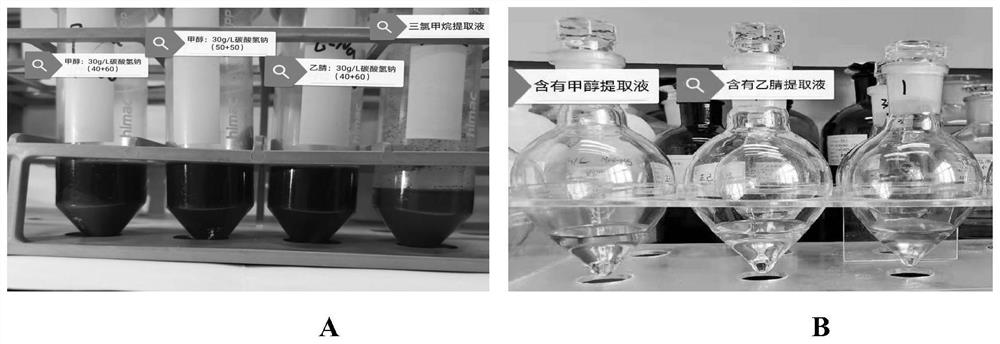

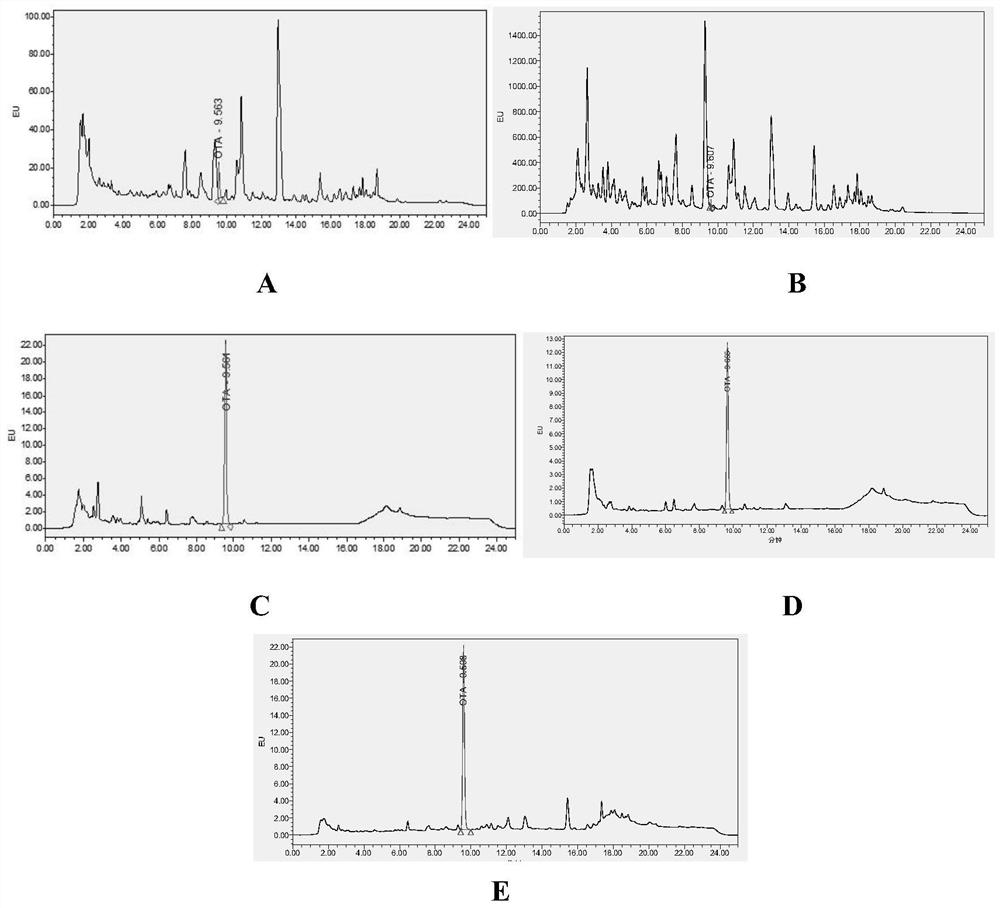

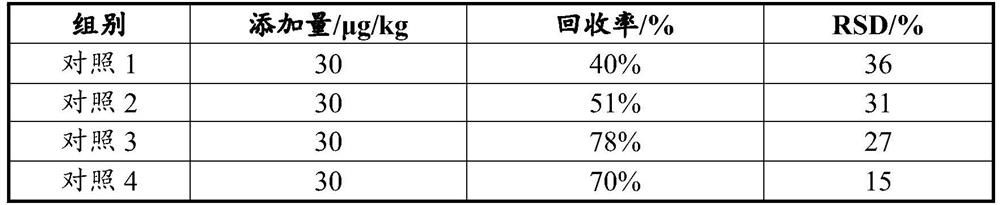

Rapid determination method suitable for ochratoxin A in licorice paste

PendingCN113804803AImprove solubilityEfficient extractionComponent separationPreparing sample for investigationSolventOchratoxins

The invention discloses a rapid and accurate detection method suitable for ochratoxin A in liquorice paste. The rapid and accurate detection method suitable for the ochratoxin A in the licorice paste is finally obtained through key control steps of selecting an extraction solvent, optimizing liquid-liquid extraction and back extraction purification, improving a leaching solution of immunoaffinity column purification and the like. When an extracting solution is prepared from a NaHCO3 solution with the concentration of 30 g / L and acetonitrile according to a volume ratio of 60:40, the liquorice paste is completely dissolved, the pH value is adjusted to be 2-3, trichloromethane is used for extraction, then an extracting solution back-extraction technology is used for purification, an immunoaffinity column is used for re-purification, then determination is conducted, and the method is simple and rapid, good in purification effect, capable of effectively removing impurity interference and high and stable in recovery rate. The detection method provided by the invention is used for detecting the ochratoxin A in the licorice paste, the recovery rate 9 is as high as 0%, the problem that the ochratoxin A in the licorice paste is difficult to rapidly and accurately determine by the existing method is effectively solved, and the low-cost, rapid and accurate determination method for content of the ochratoxin A in the licorice paste is established.

Owner:乌鲁木齐海关技术中心

Cored wire, its application, vanadium and nitrogen alloyed molten steel, preparation method of vanadium and nitrogen alloyed molten steel, and vanadium and nitrogen micro-alloyed steel

The invention provides a cored wire and its application. The cored wire comprises a core layer and an external layer wrapping the core layer, wherein the core layer is a mixture containing a vanadium-nitrogen alloy, iron silicon nitride, a titanium-iron alloy and an iron-calcium alloy. The invention also provides a vanadium and nitrogen alloyed molten steel, and a preparation method thereof. The method comprises the steps of feeding the cored wire into molten steel to be vanadium and nitrogen alloyed, and carrying out vanadium and nitrogen alloying. The invention further provides a vanadium and nitrogen micro-alloyed steel. The vanadium and nitrogen micro-alloyed steel is obtained by casting the vanadium and nitrogen alloyed molten steel. The cored wire can be used for realizing the alloying of molten steel vanadium and nitrogen, can effectively increase the oxygen content as needed without influencing the vanadium content, enables vanadium-containing steel with a higher content of nitrogen to be produced as needed, and can realize high and stable nitrogen recovery rate.

Owner:SICHUAN PAN YAN TECH

Titanium-containing cored wire and its application, titanium alloyed molten steel and its preparation method, and a titanium-containing alloy steel

The invention provides a titanium-containing core-spun yarn which comprises an inner sheath, an outer sheath, aluminum powder and titanium-iron powder, wherein the inner sheath is wrapped outside the titanium-iron powder, and the aluminum powder is filled between the inner sheath and the outer sheath. The invention provides application of the titanium-containing core-spun yarn in preparing titanium alloying molten steel. The invention provides a preparation method of the titanium alloying molten steel, which comprises the following steps: feeding the titanium-containing core-spun yarn into molten steel to be subjected to titanium alloying, and carrying out titanium alloying. The invention provides a titanium alloying molten steel prepared by the method. The invention provides a titanium-containing alloy steel which is prepared by casting the titanium alloying molten steel. In the preferable embodiment, the core-spun yarn is used for implementing titanium alloying of molten steel, and the titanium recovery rate is high and stable (80-85%), thereby effectively enhancing the quality of the molten steel.

Owner:SICHUAN PAN YAN TECH

Core spun yarn and application thereof, vanadium nitrogen alloyed molten steel and preparation method thereof, and vanadium nitrogen microalloyed steel

The invention provides a core spun yarn and application thereof. The core spun yarn comprises a core layer and an outer layer wrapping the core layer, and the core layer is a mixture comprising vanadium nitrogen alloy, ferro-silicon nitride, iron alloy and fluorspar. The invention provides vanadium nitrogen alloy molten steel and a preparation method thereof, and the method includes feeding of the core spun yarn into the to-be-vanadium and nitrogen alloyed molten steel for vanadium nitrogen alloying. The invention provides vanadium nitrogen microalloyed steel, and the vanadium nitrogen microalloyed steel is casted by the vanadium and nitrogen alloyed molten steel. The core spun yarn is used for realizing molten steel vanadium and nitrogen alloying, nitrogen content can be effectively increased without affecting the vanadium content according to the need, vanadium containing steel with higher nitrogen content can be produced in the need of the molten steel, and the recovery rate of nitrogen is high and stable. The vanadium nitrogen microalloyed steel casted by the vanadium and nitrogen alloyed molten steel produced by use of the core spun yarn for the molten steel vanadium and nitrogen alloying is high in yield strength and tensile strength.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com