Cored wire, its application, vanadium and nitrogen alloyed molten steel, preparation method of vanadium and nitrogen alloyed molten steel, and vanadium and nitrogen micro-alloyed steel

A vanadium-nitrogen alloy and cored wire technology is applied in the fields of cored wire and its application, vanadium-nitrogen alloyed molten steel and its preparation, and vanadium-nitrogen microalloyed steel, and achieves stable and stable recovery rate, high recovery rate, and yield strength and high yield strength. The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

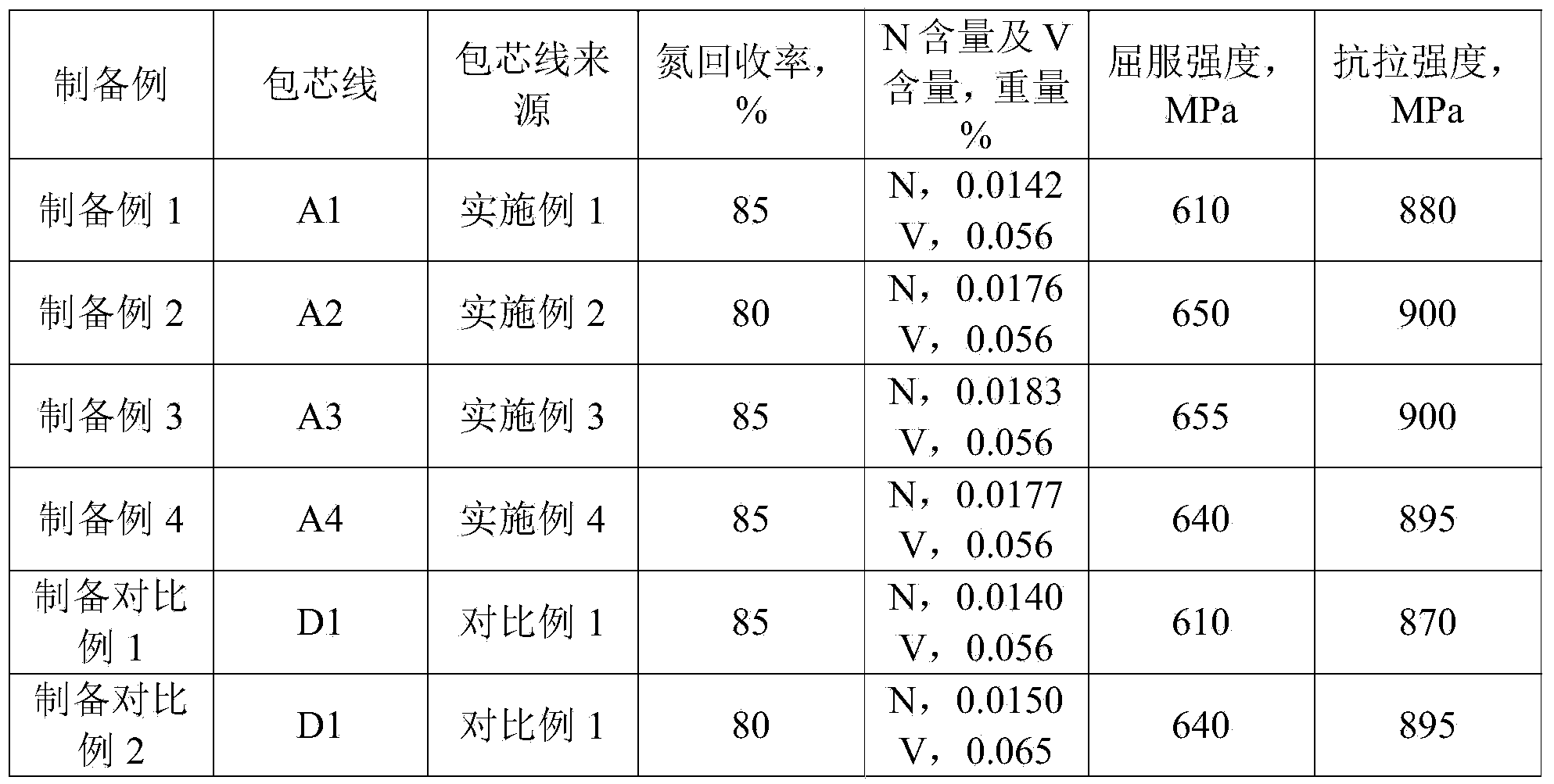

[0032] The invention provides a method for preparing vanadium-nitrogen alloyed molten steel. The method comprises: feeding the cored wire of the invention into molten steel to be vanadium-nitrogen alloyed for vanadium-nitrogen alloying.

[0033] According to the preparation method of vanadium-nitrogen alloyed molten steel of the present invention, in order to facilitate the rapid feeding of the cored wire into the molten steel, and at the same time in order to improve the yield strength and tensile strength of the vanadium-nitrogen micro-alloyed steel, it is preferable to carry out the vanadium-nitrogen alloying process , Carry out vanadium nitrogen alloying under dynamic conditions, dynamic conditions can be achieved by shaking or rotating the ladle, for example, the ladle can be shaken while the cored wire is fed into the molten steel in the ladle through the wire feeding device.

[0034] According to the preparation method of vanadium-nitrogen alloyed molten steel of the pre...

Embodiment 1

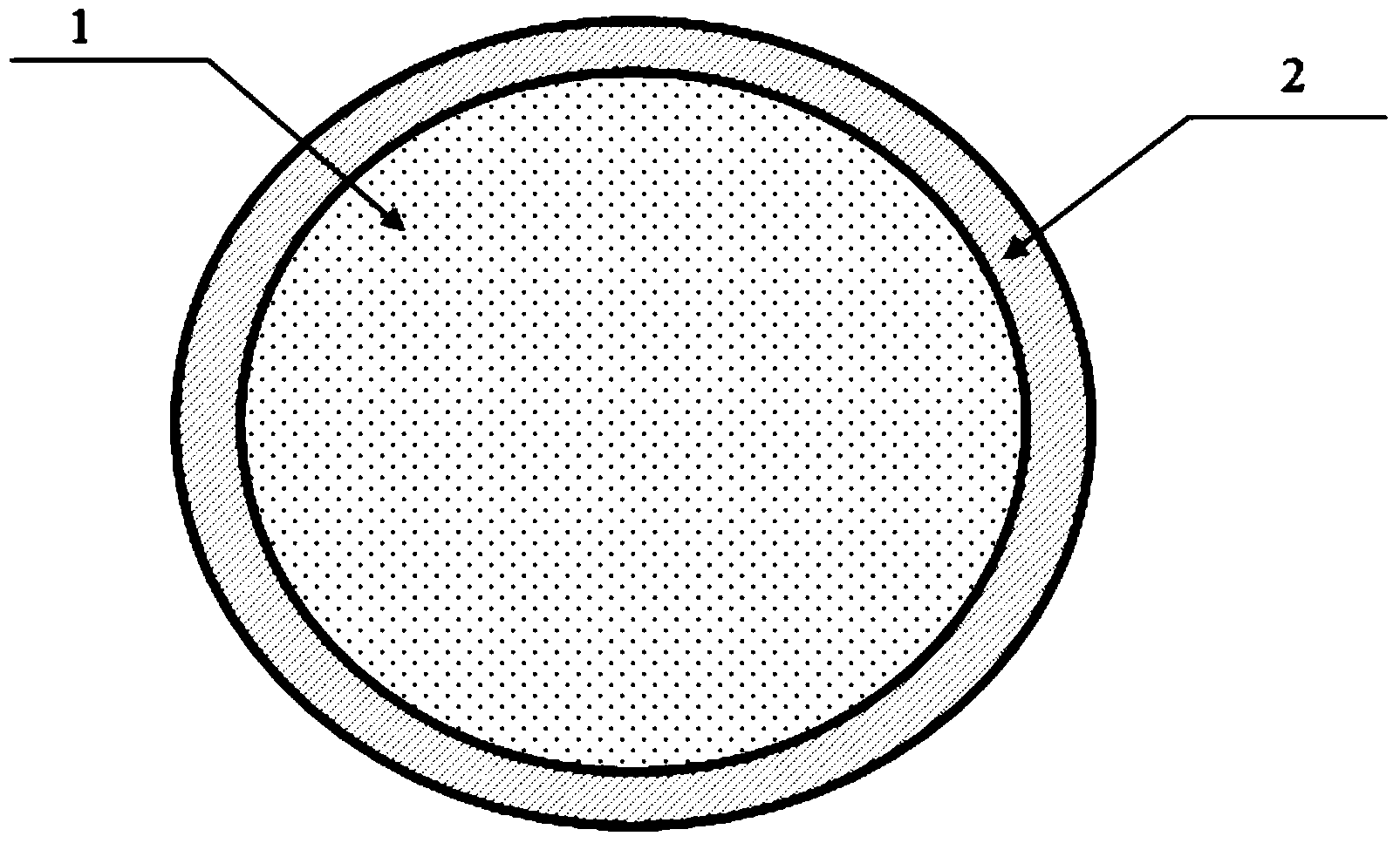

[0049] A cored wire A1 (with an outer diameter of 12mm), including a core layer and an outer layer wrapping the core layer. The core layer is made of vanadium nitrogen alloy, silicon manganese nitride, titanium iron alloy and iron calcium alloy The outer layer is made of cold-rolled strip steel (brand St12), wherein, the powder contains vanadium-nitrogen alloy (VN16, vanadium content 78% by weight, N content 16% by weight): 97 % by weight, silicon manganese nitride (N content is 28% by weight, Si content is 40% by weight, Mn content is 10% by weight, the rest is a small amount of Fe and other unavoidable impurity elements): 1% by weight, ferro-titanium alloy: 1% by weight, iron-calcium alloy (Ca content is 30% by weight, the rest is Fe and unavoidable other impurity elements): 1% by weight, titanium-iron alloy is FeTi40 (Ti content is 40% by weight, the rest is Fe and unavoidable other impurity elements) other impurity elements).

Embodiment 2

[0051] A cored wire A2 (with an outer diameter of 12mm), including a core layer and an outer layer wrapping the core layer, the core layer is made of powder (particles) of vanadium nitrogen alloy, silicon manganese nitride, titanium iron alloy and iron calcium alloy The diameter is less than 3mm), and the outer layer is a skin made of cold-rolled strip steel (brand St12), wherein, the powder contains vanadium-nitrogen alloy (VN16, vanadium content 78% by weight, N content 16% by weight): 47 % by weight, silicon manganese nitride (N content is 28% by weight, Si content is 40% by weight, Mn content is 10% by weight, the rest is a small amount of Fe and other unavoidable impurity elements): 13% by weight, ferro-titanium alloy: 25% by weight, iron-calcium alloy (Ca content is 30% by weight, the rest is Fe and unavoidable other impurity elements): 15% by weight, titanium-iron alloy is FeTi40 (Ti content is 40% by weight, the rest is Fe and unavoidable other impurity elements) other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com