Solid phase extraction method of N-nitrosodimethylamine in water

A nitrosodimethylamine, solid-phase extraction column technology, applied in separation methods, chemical instruments and methods, extraction water/sewage treatment, etc., can solve the problem of expensive materials, low recovery efficiency, and large environmental pollution. problems, to achieve the effect of simple and easy operation, avoiding easy emulsification of the interface, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

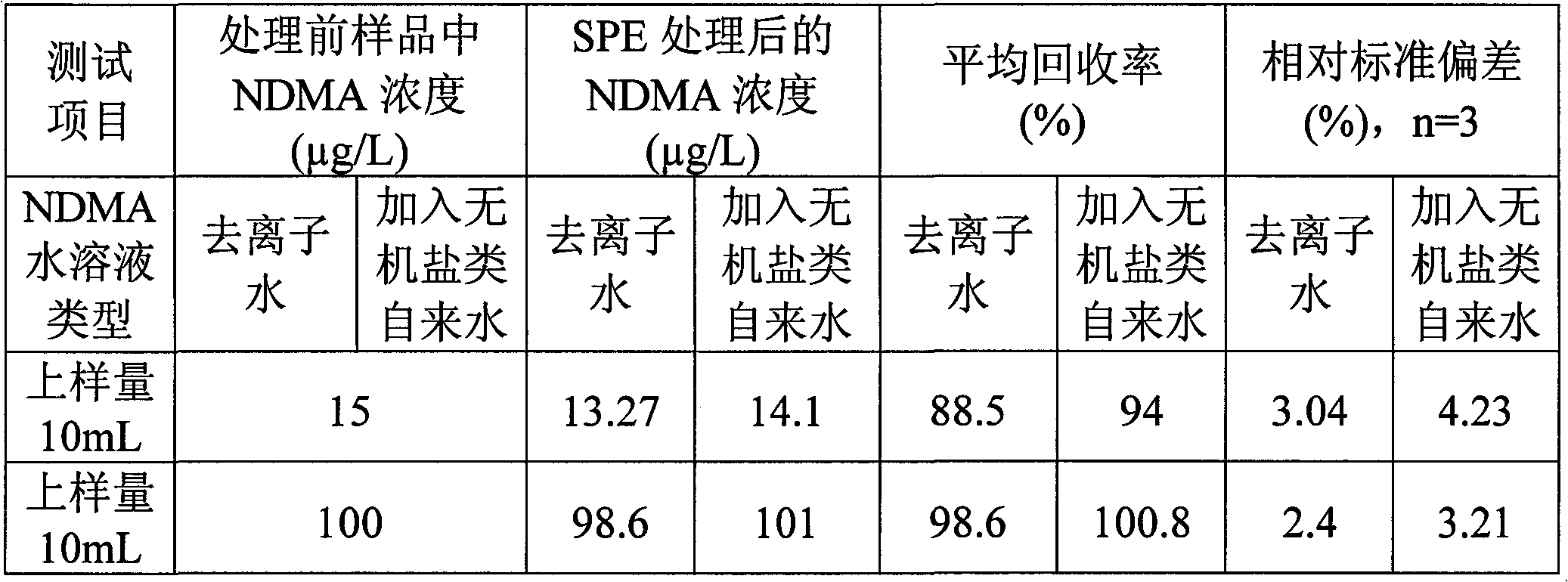

Examples

Embodiment 1

[0024] (1) Select a tube with a size of 5mL, and place a polypropylene sieve plate (purchased from Tianjin Bona Aijieer Technology Co., Ltd.) on the bottom, select 400mg of a particle size of 20 mesh, and a specific surface area of 1000m 2 / g of activated carbon (purchased from Supelco company, its English name is activated coconut charcoal), the activated carbon is washed and stirred into a paste, then suction filtered until it is nearly dry and in the form of agglomerates, and then transferred to the tube for filling. Soak and wash with methanol and deionized water in sequence, drain, and then compress the upper layer with a layer of sieve plate, and package it for later use.

[0025] (2) Activate the above-prepared solid-phase extraction column with methanol and deionized water of one column volume in turn, drain it under negative pressure, measure 5 mL of the aqueous solution of the NDMA standard with a concentration of 1 ng / μL, and use 2-5 mL Pass the sample through the...

Embodiment 2

[0027] The particle size of activated carbon is 40 mesh, and other steps are the same as implementation 1.

Embodiment 3

[0029] The specific surface area of activated carbon is 1500m 2 / g, other steps are the same as implementation 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com