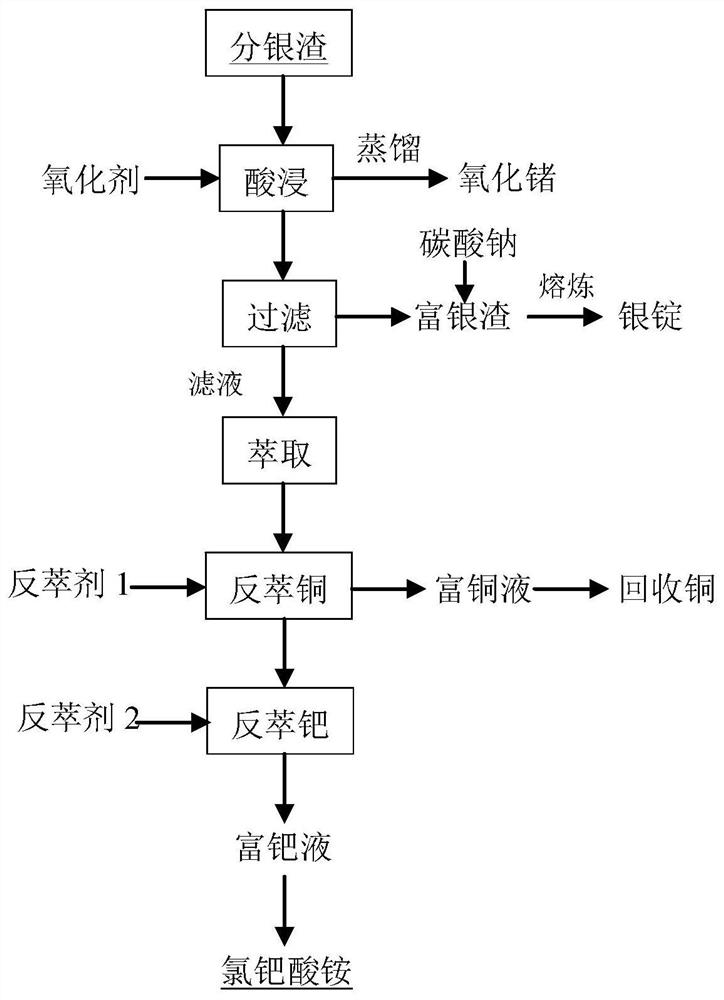

Method for separating and extracting silver, palladium, copper and germanium in silver separation residues

A technology for separating silver slag and silver, which is applied in the field of separation and extraction of silver, palladium, copper and germanium in silver slag, can solve the problems of complex impurity components, low germanium grade, and long process flow, and achieve simple operation, low equipment investment, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

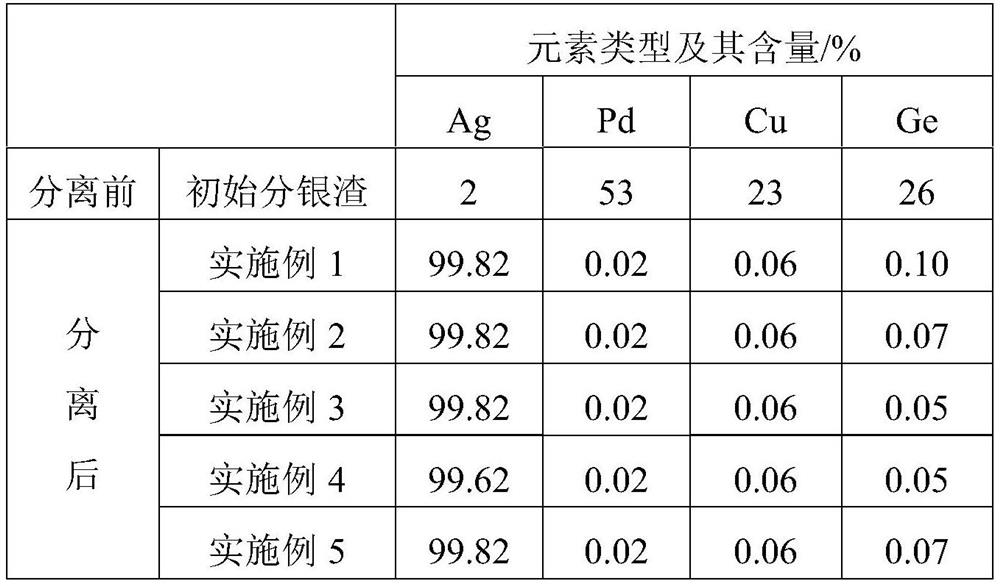

Embodiment 1

[0040] (1) Add 100 g of silver-separating slag to slurry, stir evenly, add 5mol / L hydrochloric acid and distill and purify at 90°C to obtain germanium chloride liquid, wherein, feed chlorine gas while heating (the feed amount of chlorine gas is a theoretical amount 1.5 times of 1.5 times); germanium chloride is hydrolyzed and post-treated to obtain germanium oxide; (2) the silver-separating slag that is reacted through step (1) is filtered to obtain leaching slag and filtrate, and the leaching slag and sodium carbonate are mixed uniformly at 1100 Smelting under ℃, obtain silver ingot, after measuring, the recovery rate of silver is 98.3%; (3) in the filtrate that step (2) obtains, add organic extract (wherein organic extract comprises 10% extraction agent LIX63 and 2 % modified preparation MIBK) to simultaneously extract palladium and copper elements, the volume ratio of the formed organic phase to the aqueous phase is 1:1, and the extraction time is 3min; Obtain copper-rich s...

Embodiment 2

[0042] (1) Add 100 g of silver-separating slag to water slurry, stir evenly, add 5mol / L hydrochloric acid and distill and purify at 100° C. to obtain germanium chloride liquid, wherein, feed chlorine gas while heating (the feed amount of chlorine gas is a theoretical amount 1.2 times of 1.2 times); germanium chloride is hydrolyzed and post-treated to obtain germanium oxide; (2) the silver-separating slag through step (1) reaction is filtered to obtain leaching slag and filtrate, and the leaching slag and sodium carbonate are mixed uniformly at 1100 Smelting under ℃, obtain silver ingot, after measuring, the rate of recovery of silver is 98.3%; (3) add organic extract (wherein organic extract comprises 20% extraction agent N235 and 5% in the filtrate that step (2) obtains) % modified preparation TBP) to extract the palladium element, the volume ratio of the formed organic phase to the aqueous phase is 1:1, and the extraction time is 3min; (4) the raffinate obtained in step (3) i...

Embodiment 3

[0044] (1) 100g of silver slag is added with water to adjust the slurry, stir evenly, add 7mol / L hydrochloric acid and distill and purify at 95°C to obtain germanium chloride liquid, wherein, feed chlorine gas while heating (the feed amount of chlorine gas is a theoretical amount 1.2 times of 1.2 times); germanium chloride is hydrolyzed and post-treated to obtain germanium oxide; (2) the silver-separating slag through step (1) reaction is filtered to obtain leaching slag and filtrate, and the leaching slag and sodium carbonate are mixed uniformly at 1100 Smelting under ℃, obtain silver ingot, after measuring, the recovery rate of silver is 98.3%; (3) add organic extraction liquid (wherein the extraction agent LIX63 that comprises 30% in the organic extraction liquid) in the filtrate that step (2) obtains, Extract palladium and copper elements at the same time, the volume ratio of the formed organic phase to the aqueous phase is 1:1, and the extraction time is 3 minutes; (4) fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com