Low-dosage cement chromium-removing grinding aid and preparation method thereof

A technology of grinding aids and cement, which is applied in the field of low-volume cement chromium removal grinding aids and its preparation, can solve the problems of inability to compound grinding aids, high use costs, and inconvenient promotion, and achieve low production costs, Improved physical properties and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

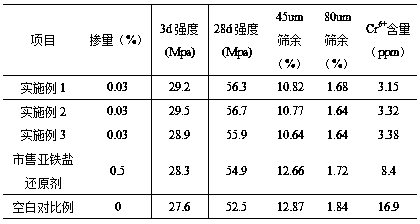

Examples

Embodiment 1

[0024] A low-volume cement chromium removal grinding aid is specifically prepared from the following raw materials in parts by weight: 20 parts of triethanolamine, 20 parts of ethylene glycol, 25 parts of antimony trichloride, and 5 parts of ethanol.

[0025] Described triethanolamine is the industrial product of content 85%;

[0026] Described ethylene glycol is the industrial product of content 95%.

[0027] The antimony trichloride is 99.5% of industrial product.

[0028] The ethanol is industrial ethanol with a content of 95%.

[0029] A preparation method of a low-volume cement chromium removal grinding aid:

[0030] (1) Dissolving certain parts by weight of antimony trichloride in ethylene glycol to form a solution;

[0031] (2) Add triethanolamine to the above solution, and pass cooling water into the reaction kettle. After the dropwise addition is complete and the temperature of the system is stable after the reaction is complete, the temperature is raised to 60° C...

Embodiment 2

[0034] A low-volume cement chromium removal grinding aid is specifically prepared from the following raw materials in parts by weight: 30 parts of diethanol monoisopropanolamine, 30 parts of ethylene glycol, 35 parts of antimony trichloride, and 10 parts of ethanol.

[0035] Described diethanol monoisopropanolamine is a content 85% industrial product:

[0036] Described ethylene glycol is the industrial product of content 95%.

[0037] The antimony trichloride is 99.5% of industrial product.

[0038] The ethanol is industrial ethanol with a content of 95%.

[0039] A preparation method of a low-volume cement chromium removal grinding aid:

[0040] (1) Dissolving certain parts by weight of antimony trichloride in ethylene glycol to form a solution;

[0041] (2) Add diethanol monoisopropanolamine to the above solution, and pass cooling water into the reaction kettle. After the dropwise addition is complete and the temperature of the system is stable after the reaction is com...

Embodiment 3

[0044] A low-volume cement chromium removal grinding aid is specifically prepared from the following raw materials in parts by weight: 40 parts of diethanol monoisopropanolamine, 20 parts of ethylene glycol, 40 parts of antimony trichloride, and 15 parts of ethanol.

[0045] Described diethanol monoisopropanolamine is a content 85% industrial product:

[0046] Described ethylene glycol is the industrial product of content 95%.

[0047] The antimony trichloride is 99.5% of industrial product.

[0048] The ethanol is industrial ethanol with a content of 95%.

[0049] A preparation method of a low-volume cement chromium removal grinding aid:

[0050] (1) Dissolving certain parts by weight of antimony trichloride in ethylene glycol to form a solution;

[0051] (2) Add alcohol amine substances to the above solution, and pass cooling water into the reaction kettle. After the dropwise addition is complete and the temperature of the system is stable after the reaction is complete,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com