Antimony-doped tin dioxide coated porous manganese dioxide composite electrode material and preparation

A tin dioxide and manganese dioxide technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of high temperature calcination, unstable structure, complicated process, etc., to improve cycle stability and active material utilization rate, improve utilization rate , the effect of increasing the specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

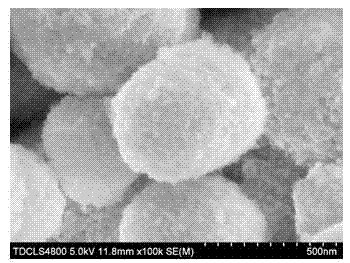

[0019] Prepare water-ethylene glycol (H 2 O:C 2 h 6 o 2 =9:1) Mix 100mL of the solution, heat up to 30°C, add 1g of PVP, stir well to dissolve. Add 1.69g of MnSO 4 .H2 O solid, stirred to dissolve. Continue magnetic stirring, add 12.5mL of 1mol / L Na 2 CO 3 The aqueous solution was slowly added dropwise to the MnSO 4 In the solution, the stirring reaction was continued at 30° C. for 2 h, and a milky white precipitate a was formed, which was allowed to stand at room temperature for 3 h. The white precipitate a was centrifuged (3500r / min, 5min), washed with ethanol and deionized water respectively until the supernatant was neutral. Dry a in air at 60°C for 2.5h to obtain MnCO 3 particle. SEM image ( figure 1 ) shows that the prepared MnCO 3 The particle size is 400-550nm, and the distribution is uniform.

[0020] Prepare a water-ethanol solution (C 2 h 6 O:H 2 O=7:1) 40mL, weigh 0.35g (1mmol) of SnCl 4 .5H 2 O and 0.009 g (0.04 mmol) of SbCl 3 Dissolve in the m...

Embodiment 2

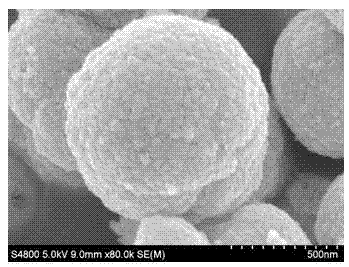

[0023] MnCO 3 Particle preparation is the same as Step 1 of Example 1. Prepare a water-ethanol solution (C 2 h 6 O:H 2 O=6:2) 20mL, weigh 0.175g (0.5mmol) of SnCl 4 .5H 2 O and 0.0069 g (0.03 mmol) of SbCl 3 Dissolve in the mixed solution and stir for 40 minutes at 27°C to make it into a sol. Weigh 0.575g (5mmol) MnCO 3 Add it into the sol, sonicate for 1 hour, and react with magnetic stirring at 35°C for 2.5 hours to make it gel. Cool to room temperature, stand at room temperature for 24h, centrifuge (3500r / min, 5min), dry in 55°C air atmosphere for 3h, put into tube resistance furnace, in air atmosphere, at a heating rate of 2.5°C / min The temperature was raised to 400° C., and then calcined at a constant temperature of 400° C. for 2.5 hours to obtain an antimony-doped tin dioxide-coated porous manganese dioxide composite electrode material. Characterize the prepared material, the SEM image shows that the particle size of the prepared material is 400nm-600nm, and the...

Embodiment 3

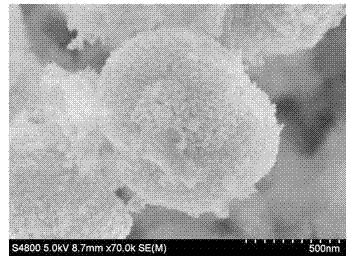

[0025] MnCO 3 Particle preparation is the same as Step 1 of Example 1. Prepare a water-ethanol solution (C 2 h 6 O:H 2 O=6.5:1.5) 40mL, weigh 0.525g (1.5mmol) of SnCl 4 .5H 2 O and 0.021 g (0.09 mmol) of SbCl 3 Dissolve in the mixed solution, stir at 35°C for 0.5h to make it into a sol. Weigh 1.15g (10mmol) MnCO 3 Add it into the sol, sonicate for 2 hours, and react with magnetic stirring at 40°C for 3.5 hours to make it gel. Cool to room temperature, stand at room temperature for 15h, centrifuge (3500r / min, 5min), dry in 65°C air atmosphere for 2h, put into tube resistance furnace, in air atmosphere, at a heating rate of 2.67°C / min The temperature was raised to 450° C., and then calcined at a constant temperature of 450° C. for 3 hours to obtain the antimony-doped tin dioxide-coated porous manganese dioxide composite electrode material. Characterize the prepared material, the SEM image shows that the particle size of the prepared material is 400nm-600nm, and the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com