Preparation method of C/Sb<2>S<3> composite thin-film counter electrode material

A composite thin film and electrode material technology, applied in circuits, capacitors, photovoltaic power generation, etc., can solve the problems of restricting large-scale production and application, complex preparation process, poor electrical conductivity and catalytic performance of the film, and achieve excellent electrocatalytic performance, Effect of high electrocatalytic performance and excellent counter electrode performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Carbon nanoparticles and sodium carboxymethylcellulose were dispersed in water to obtain a carbon nanoparticle sol, and the sol was spin-coated onto fluorine-doped SnO 2 transparent conductive glass surface, after 60~100 o C is dried in vacuum to obtain a carbon nanoparticle film;

[0022] Add 1mMSbCl in DMF step by step 3 and 2mMTu, uniform and continuous stirring for a period of time to obtain the Sb-Tu precursor solution, the solution was spin-coated to the surface of the C nanoparticle film, and then put it into the N 2 In the atmosphere furnace at a heating rate of 2~8 o C / min, 350~450 o Annealing treatment at C for 0.5 hours, waiting for natural cooling to obtain C / Sb 2 S 3 Composite film.

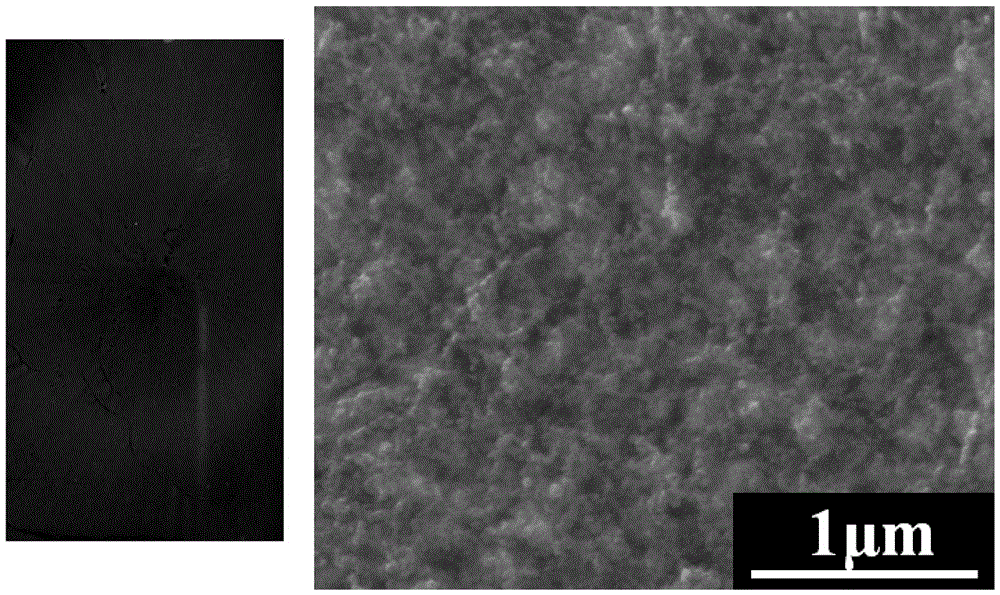

[0023] figure 1 It is the photo and SEM photo of the prepared C nanoparticle film. figure 2 It is a photo of the Sb-Tu precursor solution prepared in this example. It can be seen from the picture that the solution has good uniformity and transparency, and can be store...

Embodiment 2

[0024] Embodiment 2 Carbon nanoparticles and carboxymethyl cellulose sodium carboxylate are dispersed in water to obtain carbon nanoparticle sol, and the sol is spin-coated to the SnO2 doped with fluorine on the transparent conductive glass surface, after 60 to 100 o C is dried in vacuum to obtain a carbon nanoparticle film;

[0025] Add 1-2mMSbCl gradually in DMF 3 and 2-3mMTu, evenly and continuously stirred for a period of time to obtain the Sb-Tu precursor solution, the solution was spin-coated to the surface of the C nanoparticle film, and then put it into the N 2 In an atmosphere furnace at a heating rate of 5 o C / min, 400 o Annealing treatment at C for 0.5 hours, waiting for natural cooling to obtain C / Sb 2 S 3 Composite film.

Embodiment 3

[0026] Example 3 Carbon nanoparticles and sodium carboxymethyl cellulose are dispersed in water to obtain a carbon nanoparticle sol, and the sol is spin-coated to the SnO doped with fluorine on the transparent conductive glass surface, after 60 to 100 o C is dried in vacuum to obtain a carbon nanoparticle film;

[0027] Add 1mMSbCl in DMF step by step 3 and 2mMTu, evenly and continuously stirred for a period of time to obtain the Sb-Tu precursor solution, its solvent was evaporated to dryness in the air, and then placed in an atmosphere furnace at 400 o Annealing treatment at C for 0.5~1 hour to obtain Sb 2 S 3 Powder. Put 100mg powder in a corundum boat, cover the corundum boat with a C nanoparticle film (conductive side facing down), and heat up at a rate of 8 under the protection of the atmosphere. o C / min, 350~550 o Evaporate at constant temperature at C for 30 minutes, wait for natural cooling, and you can get C / Sb 2 S 3 Composite film.

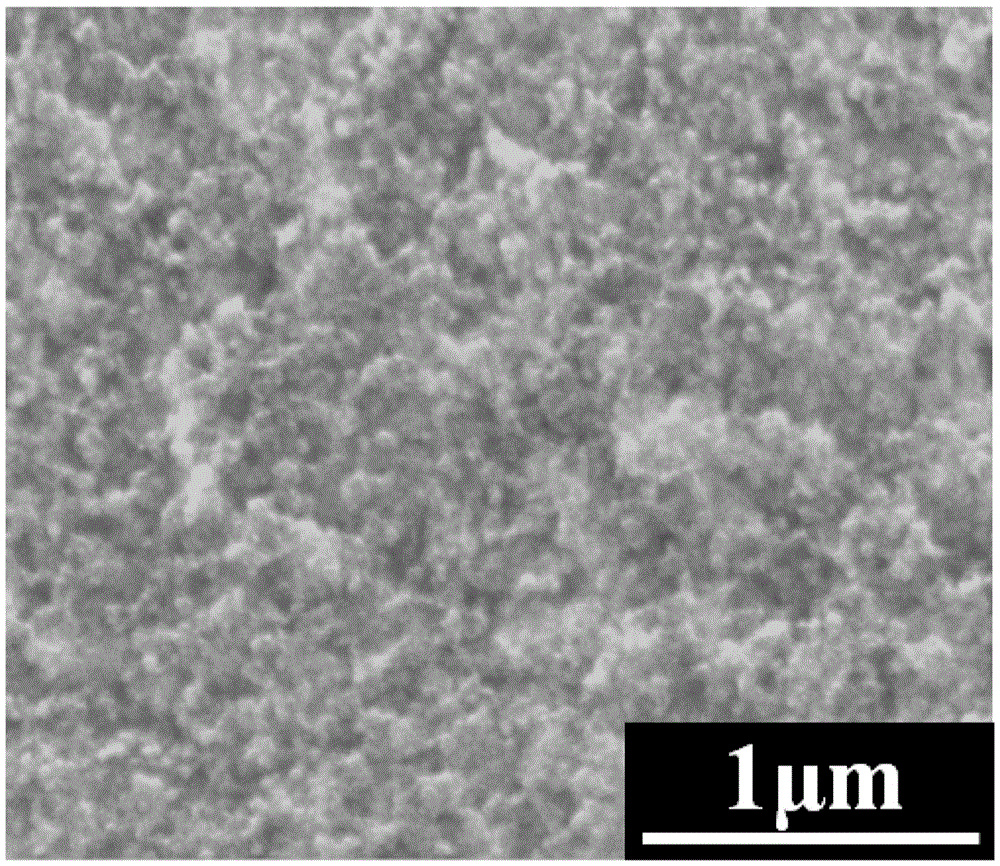

[0028] Figure 5 and 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com