Method for preparing antimony doped stannic oxide nanometer electricity-conductive powder

A tin dioxide and nano-conducting technology is applied in the field of preparing antimony-doped tin dioxide nano-conducting powder by gas-phase combustion method, which can solve the problem that it is difficult to obtain small-sized, distributed nano-crystals, difficult to remove chloride ions, and difficult to doping amount. control and other problems, to achieve the effect of small size, simple equipment and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

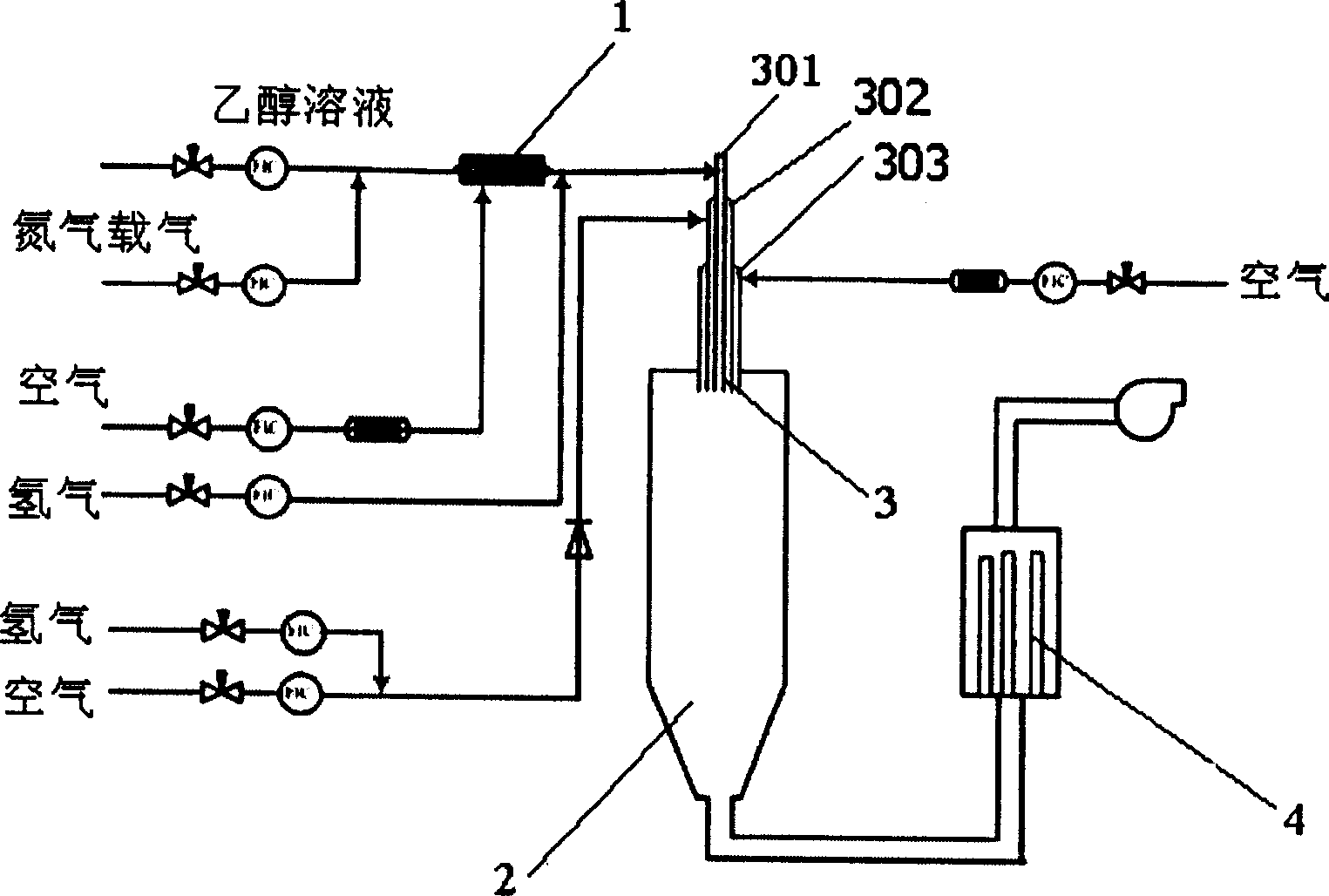

Method used

Image

Examples

Embodiment 1

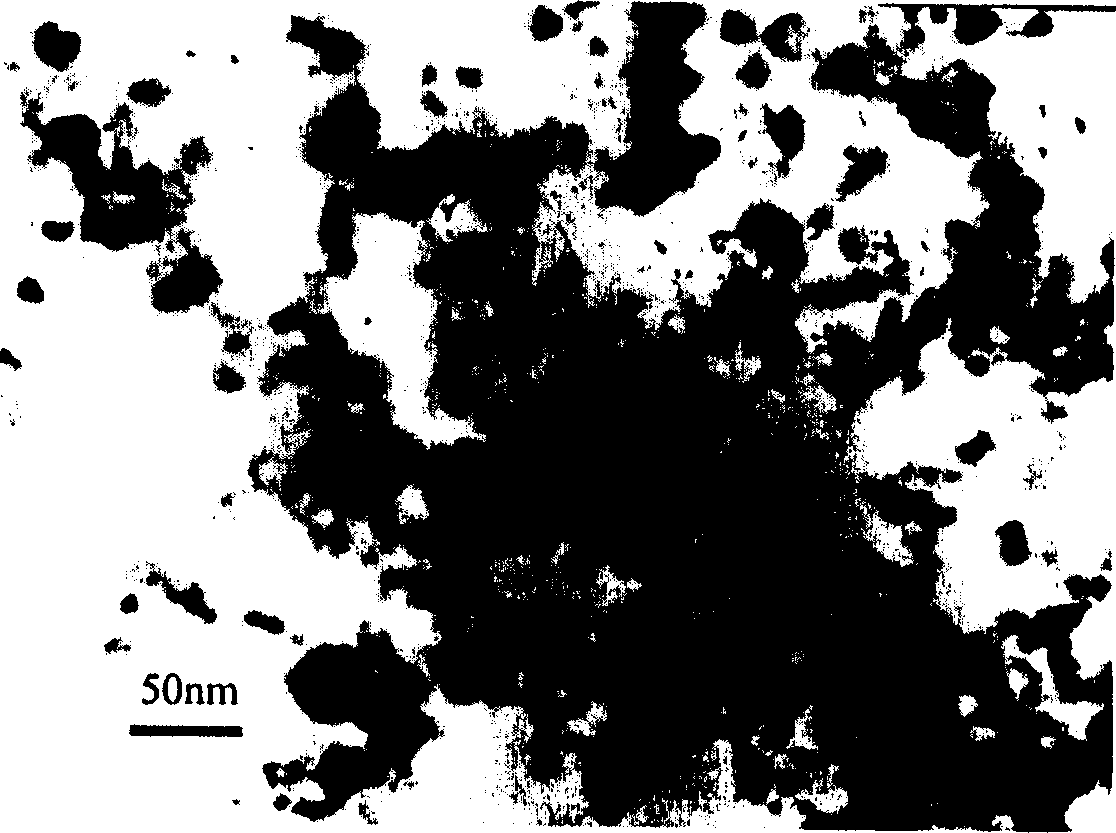

[0026] The mixed solution of tin tetrachloride, antimony trichloride and absolute ethanol (mass ratio is 10:0.5-1.5:100, flow rate 30ml / min) is N 2 (1m 3 / h) loaded into the evaporator, the temperature of the evaporator is controlled at 150°C, the vaporized and preheated air (200°C, 3m 3 / h), central tube hydrogen (0.2m 3 / h) After uniform mixing, it enters the combustion reactor from the center tube of the burner. Bicyclic hydrogen (1m 3 / h) and the second ring air (0.5m 3 The mixed gas of / h) is added from the second ring inlet to form an annular auxiliary flame, which is used to maintain the stability of the central jet flame and adjust the temperature of the reaction zone. There is another three-ring air (10m 3 / h) Added via three rings, the hydrolysis reaction of the precursor is carried out in the combustion chamber. The prepared ATO nano conductive powder has an average diameter of 8.5nm and good dispersion. See figure 2 .

Embodiment 2

[0028] The mixed solution of tin tetrachloride, antimony trichloride and absolute ethanol (mass ratio is 10:0.5-1.5:100, flow rate 10ml / min) is mixed with N 2 (1.5m 3 / h) loaded into the evaporator, the temperature of the evaporator is controlled at 250°C, the vaporized and preheated air (250°C, 3m 3 / h), central tube hydrogen (0.8m 3 / h) After uniform mixing, it enters the combustion reactor from the center tube of the burner. Bicyclic hydrogen (3m 3 / h) and the second ring air (1m 3 The mixed gas of / h) is added from the second ring inlet to form an annular auxiliary flame, which is used to maintain the stability of the central jet flame and adjust the temperature of the reaction zone. There is another three-ring air (3m 3 / h) Added via three rings, the hydrolysis reaction of the precursor is carried out in the combustion chamber. The prepared ATO nano conductive powder has an average diameter of 22nm and good dispersion. See image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com