Antimony-carbon nano-tube-carbon composite material, as well as preparation method and application thereof

A technology of carbon composite materials and carbon nanotubes, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process, expensive raw materials, fast capacity decay, etc., to achieve repeatable Good performance, abundant sources, and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

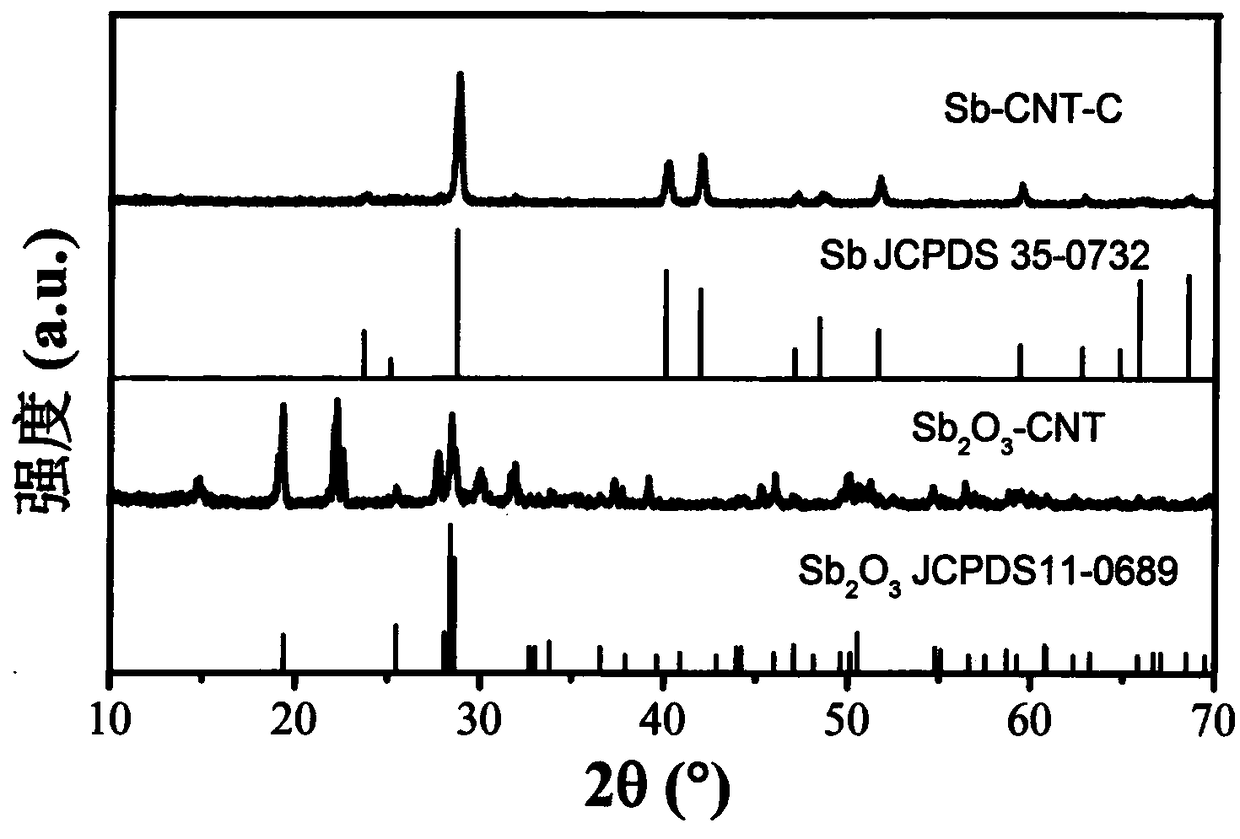

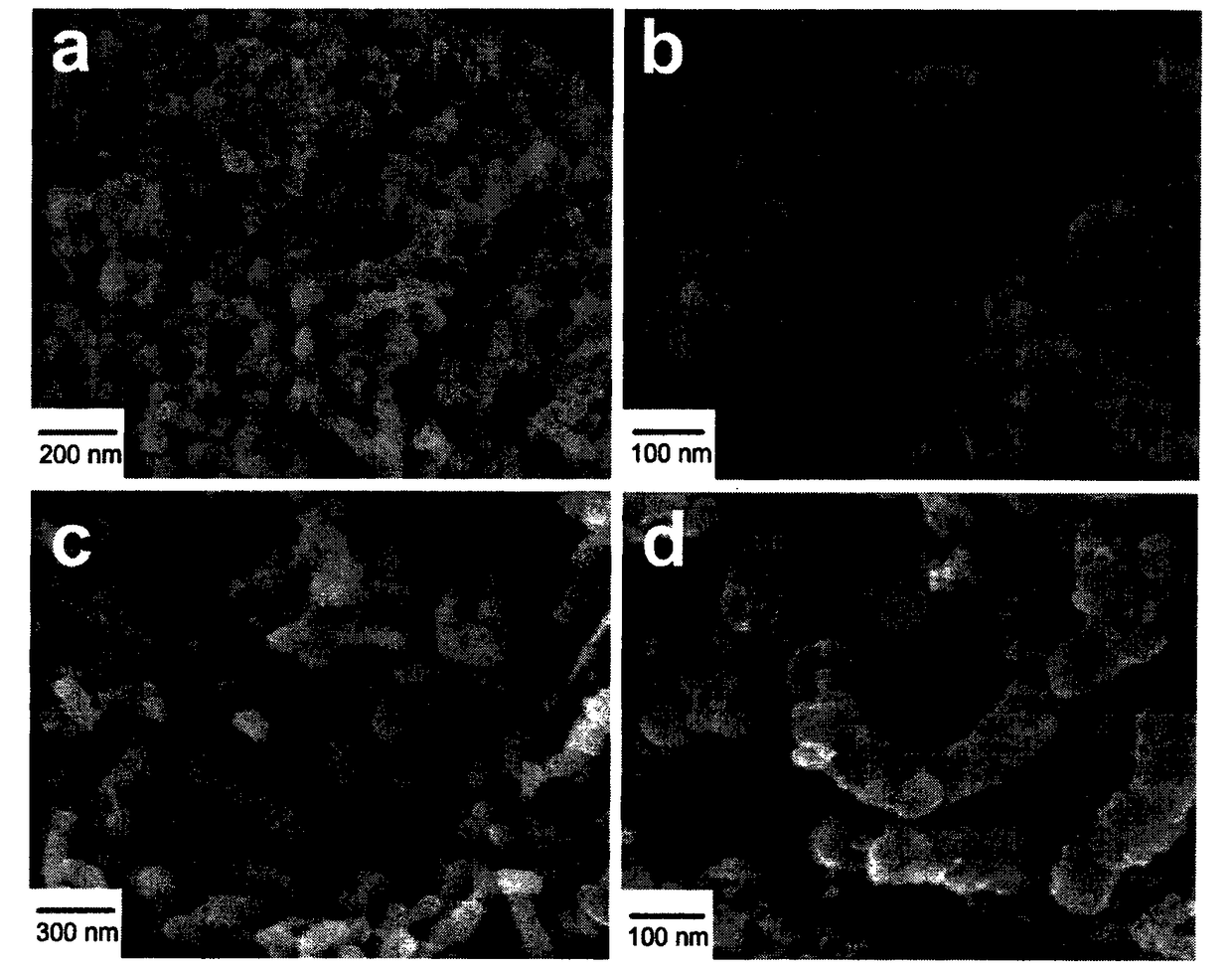

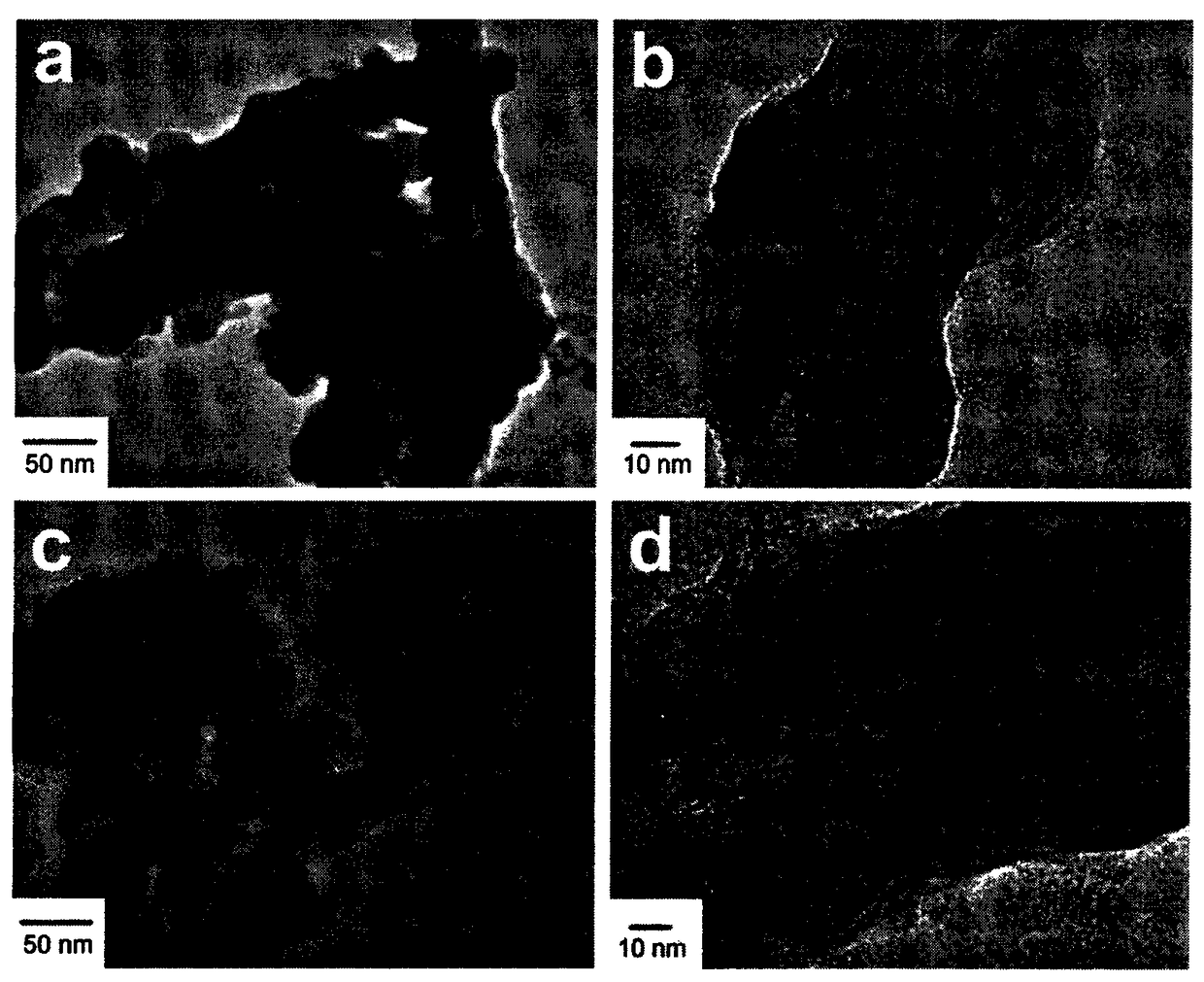

[0030] One, a kind of preparation method of antimony / carbon nanotube / carbon composite material:

[0031] (1) Treat the original carbon nanotubes with a mixed solution of sulfuric acid and nitric acid with a volume ratio of 1:1 at 70° C. for 1 hour, then dilute, suction filter, wash, dry at 80° C. overnight, and collect the product for later use;

[0032] (2) Dissolve the acidified carbon nanotubes, polyethylene glycol (200) and sodium lauryl sulfate in 40 mL of absolute ethanol at a mass ratio of 0.05:1:1, and sonicate for 2 hours until the carbon tubes are dispersed Uniformly, then 4mmol of antimony trichloride (SbCl 3 ) was dissolved in the above mixed solution, and stirred for 1h under magnetic force;

[0033] (3) Measure 27mL of 1M sodium hydroxide solution with a constant pressure separating funnel, add it dropwise to the above mixed solution, and continue magnetic stirring for 1.5h;

[0034] (4) Transfer the mixed solution to a 100 mL polytetrafluoroethylene-lined auto...

Embodiment 2

[0042] A preparation method of antimony / carbon nanotube / carbon composite material:

[0043] (1) Treat the original carbon nanotubes with a mixed solution of sulfuric acid and nitric acid with a volume ratio of 1:1 at 70° C. for 1 hour, then dilute, suction filter, wash, dry at 80° C. overnight, and collect the product for later use;

[0044] (2) Dissolve the acidified carbon nanotubes, polyethylene glycol (200) and sodium lauryl sulfate in 40 mL of absolute ethanol at a mass ratio of 0.05:1:1, and sonicate for 2 hours until the carbon tubes are dispersed Uniformly, then 4mmol of antimony trichloride (SbCl 3 ) was dissolved in the above mixed solution, and stirred for 1 h under magnetic force. ;

[0045] (3) Measure 27mL of 1M sodium hydroxide solution with a constant pressure separating funnel, add it dropwise to the above mixed solution, and continue magnetic stirring for 1h;

[0046] (4) Transfer the mixed solution to a 100 mL polytetrafluoroethylene-lined autoclave, and ...

Embodiment 3

[0049] A preparation method of antimony / carbon nanotube / carbon composite material:

[0050] (1) Treat the original carbon nanotubes with a mixed solution of sulfuric acid and nitric acid with a volume ratio of 1:1 at 70° C. for 1 hour, then dilute, suction filter, wash, dry at 80° C. overnight, and collect the product for later use;

[0051] (2) Dissolve the acidified carbon nanotubes, polyethylene glycol (200) and sodium lauryl sulfate in 40 mL of absolute ethanol at a mass ratio of 0.05:1:1, and sonicate for 2 hours until the carbon tubes are dispersed Uniformly, then 4mmol of antimony trichloride (SbCl3) was dissolved in the above mixed solution, and magnetically stirred for 1h;

[0052] (3) Measure 27mL of 1M sodium hydroxide solution with a constant pressure separating funnel, add it dropwise to the above mixed solution, and continue magnetic stirring for 2h;

[0053] (4) Transfer the mixed solution to a 100 mL polytetrafluoroethylene-lined autoclave, and heat to 150° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com