Preparation method for antimony-doped tin oxide powder

A tin dioxide and antimony doping technology, which is applied in the field of nanomaterials, can solve the problems of poor powder performance and large difference in hydrolysis rate, and achieve the effect of good dispersion and fine and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

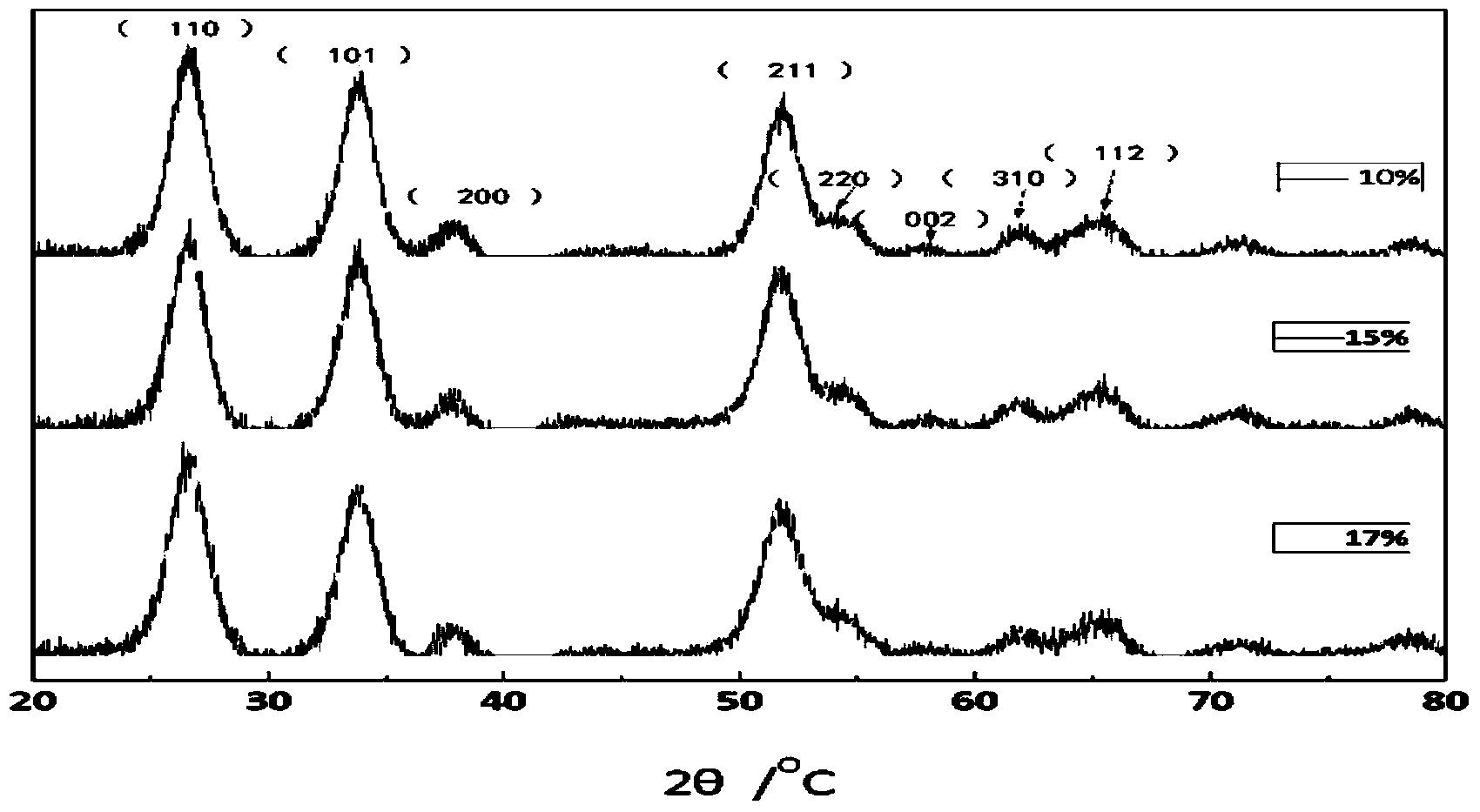

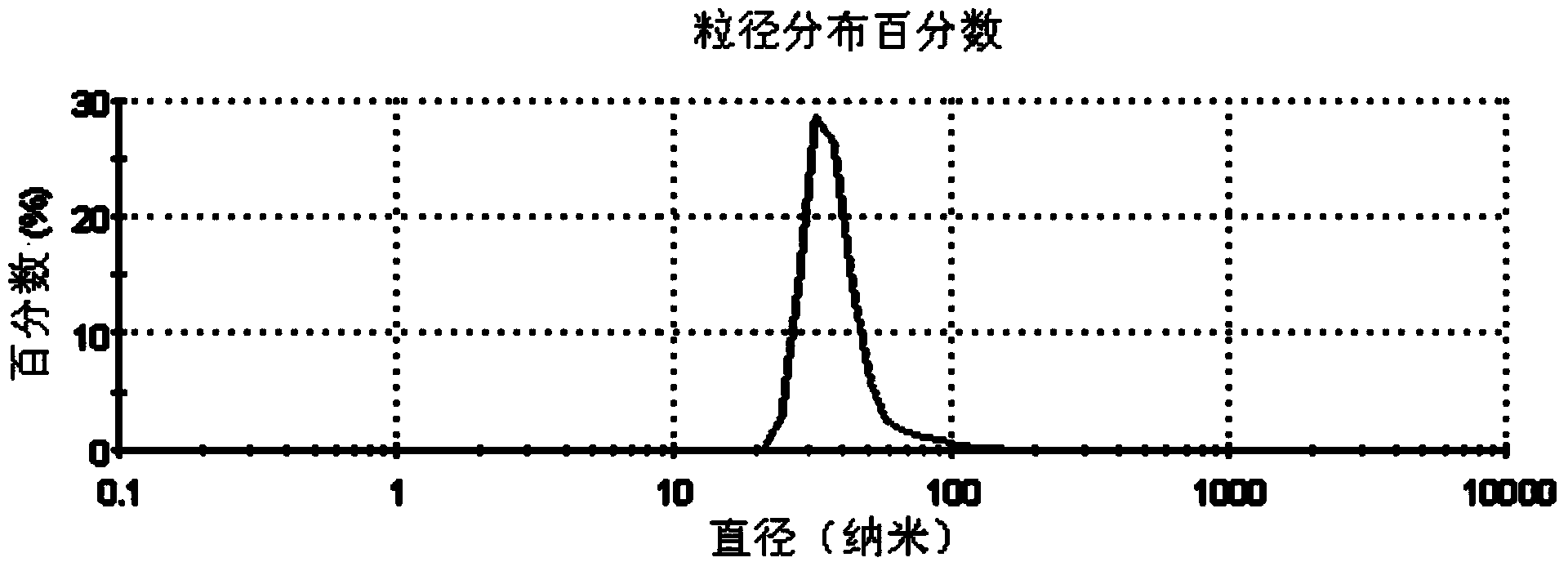

Embodiment 1

[0034] (1) Dissolve 8.76g of tin tetrachloride pentahydrate, 0.57g of antimony trichloride (10% doped with antimony) and 0.32g of tartaric acid in 40mL of 2mol / L hydrochloric acid solution to obtain a transparent solution A. Dilute concentrated ammonia water with a mass fraction of 25% to 1mol / L to obtain solution B. The bottom solution is a mixture of 150mL deionized water and 150mL ethanol, and 3g polyethylene glycol-2000 is added as a dispersant, which is solution C.

[0035] (2) Add solution A and solution B dropwise to solution C in the way of double titration, the dropping time is 53min, the stirring speed is 350rpm, and the reaction temperature is controlled at 55°C.

[0036] (3) After the titration reaction is completed, control the pH of the reaction end point at 5-6, and ripen for 2 hours; obtain a light yellow precursor suspension;

[0037] (4) Suction filter the cured precursor suspension, wash with deionized water, detect chloride ions in the filtrate with silver...

Embodiment 2

[0046] (1) Dissolve 8.76g of tin tetrachloride pentahydrate, 0.86g of antimony trichloride (15% of the amount of antimony doped) and 0.40g of citric acid in 40mL of 2mol / L hydrochloric acid solution to obtain a transparent solution A. Dilute concentrated ammonia water with a mass fraction of 25% to 1mol / L to obtain solution B. The bottom solution is a mixture of 200mL deionized water and 100mL ethanol, and 1.5g polyvinyl alcohol is added as a dispersant, which is solution C.

[0047] (2) Add A and B solutions dropwise to the bottom solution C in a double titration manner, the dropping time is 65min, the stirring speed is 600rpm, and the reaction temperature is controlled at 55°C.

[0048] (3) After the titration reaction, control the pH of the reaction end point at 5-6, and ripen for 4 hours.

[0049] (4) Suction filter the cured precursor suspension, wash with deionized water, detect chloride ions in the filtrate with silver nitrate, stop washing with water until no chloride...

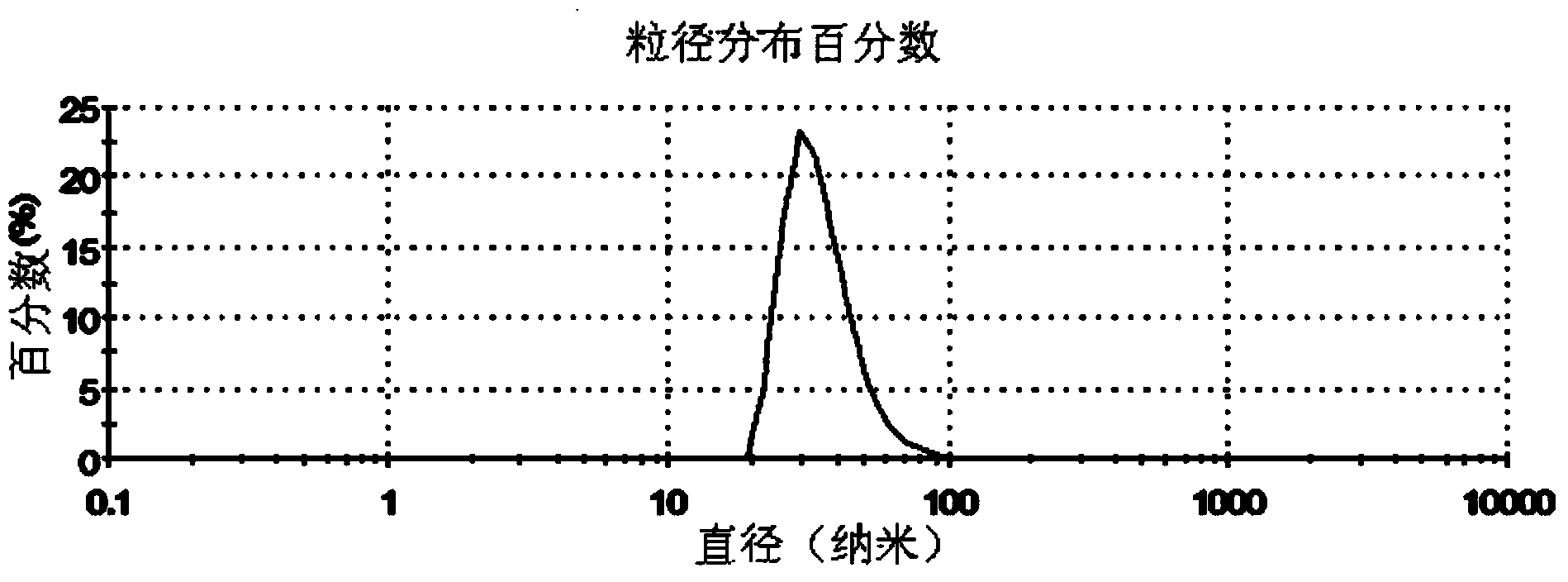

Embodiment 3

[0058] (1) Dissolve 10.51g of tin tetrachloride pentahydrate, 1.18g of antimony trichloride (17% doped with antimony) and 0.41g of tartaric acid in 40mL of 2mol / L hydrochloric acid solution to obtain a transparent solution A. Dilute concentrated ammonia water with a mass fraction of 25% to 1mol / L, which is solution B, and the bottom solution is a mixture of 150mL deionized water and 150mL ethanol with 0.8g CTAB added as a dispersant, which is solution C.

[0059] (2) Add solution A and solution B dropwise to bottom solution C in a double titration manner, the dropping time is 80min, the stirring speed is 800rpm, and the reaction temperature is controlled at 55°C.

[0060] (3) After the titration reaction, control the pH of the reaction end point at 5-6, and ripen for 2 hours.

[0061] (4) Suction filter the cured precursor suspension, wash with deionized water, detect chloride ions in the filtrate with silver nitrate, stop washing with water until no chloride ions are detected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com