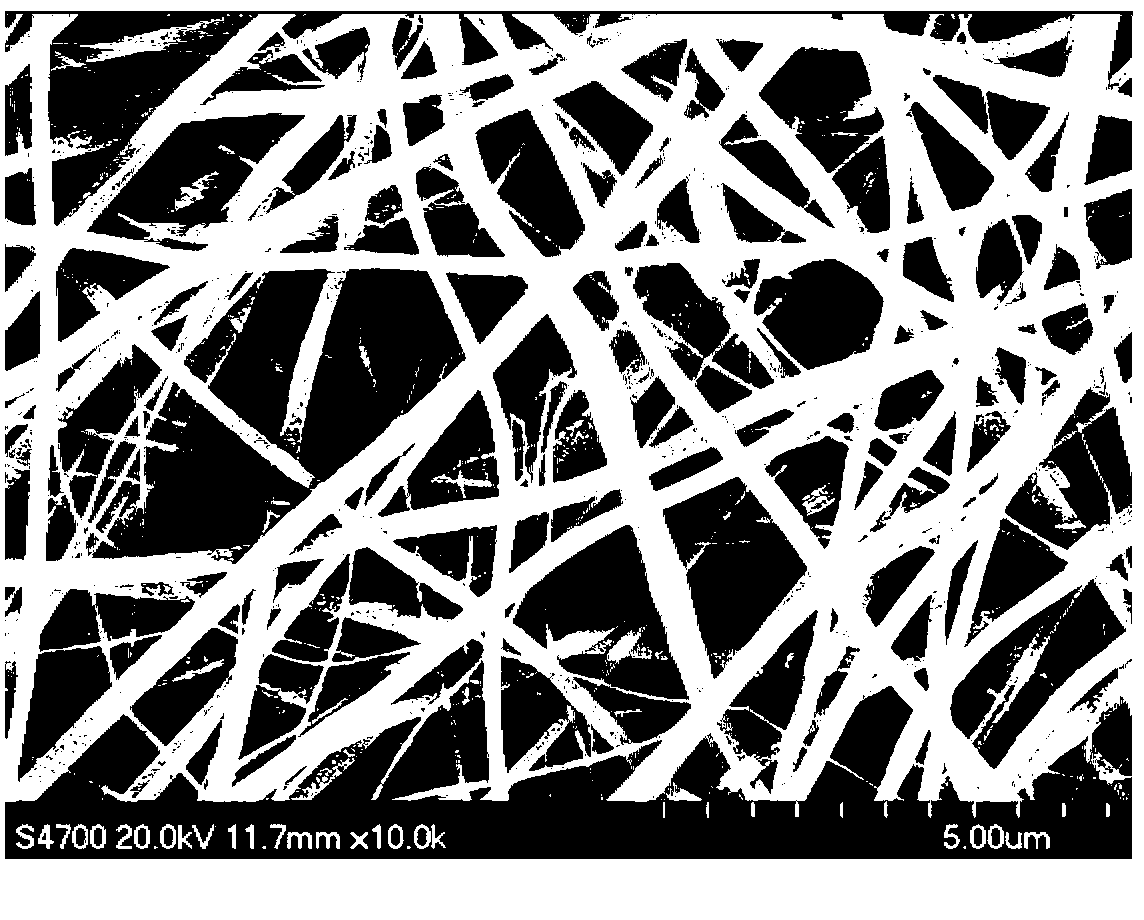

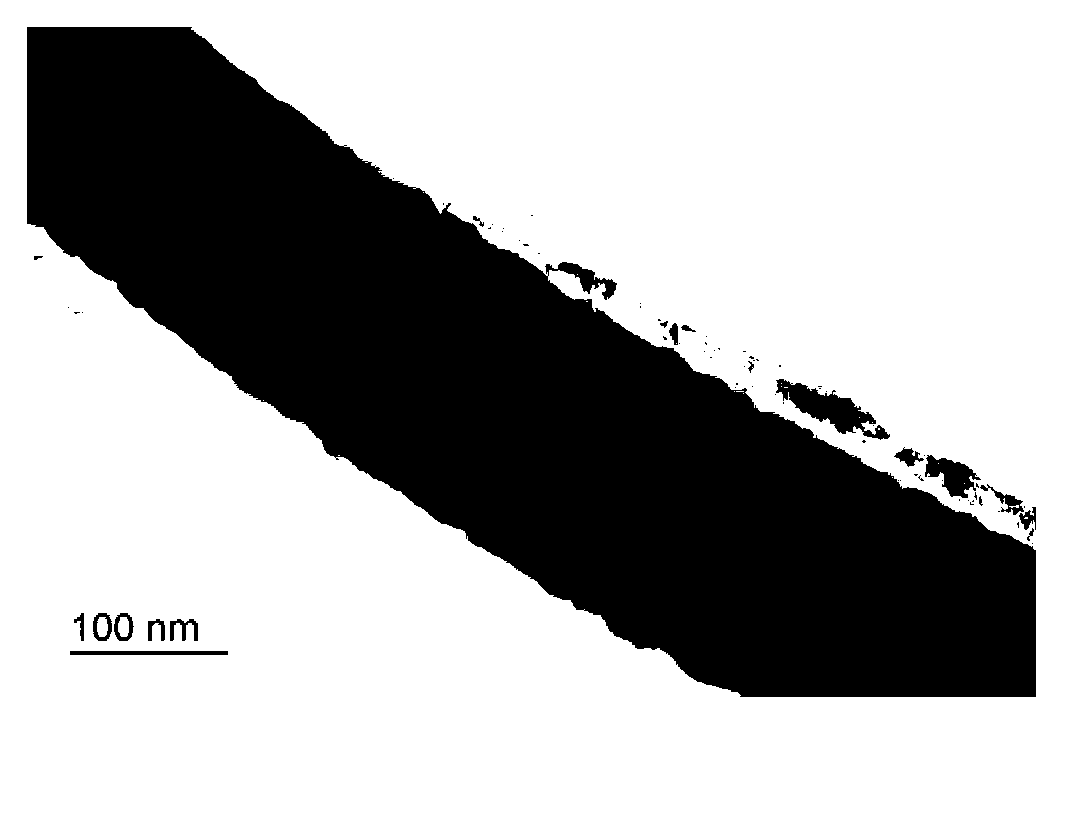

Core-shell structure TiO2/ATO nano-fiber and preparation method thereof

A core-shell structure and nanofiber technology, applied in fiber processing, fiber chemical characteristics, filament/wire forming, etc., to achieve good application prospects, high efficiency, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A: Measure 20ml of ethanol, 2ml of tetrabutyl titanate, and 2g of polyvinylpyrrolidone in a conical flask, mix and stir to obtain a uniform core layer spinning solution;

[0027] B: Weigh 100mg of tin tetrachloride pentahydrate, 40mg of antimony trichloride, and 2g of polyvinylpyrrolidone and dissolve them in 20ml of ethanol to obtain a uniform shell spinning solution;

[0028] C: Place the spinning solution prepared in step A and step B in the electrospinning equipment, spin coaxially, the spinning voltage is 15kV, the spinning distance is 15cm, the core layer spinning solution advances at a speed of 1mL / h, and the shell layer Spinning solution propulsion speed 3.3mL / h, obtain non-woven fiber mat;

[0029] D: Place the fiber mat obtained in step C in a temperature-programmed muffle furnace, increase the temperature at a rate of 4°C / min, raise the temperature to 700°C, and calcinate for 2 hours to obtain TiO 2 / ATO nanofibers.

Embodiment 2

[0031] A: (1) Measure 40mL N,N-dimethylformamide and 6g polyvinylpyrrolidone in a conical flask for mixing and stirring; (2) Measure 10mL tetrabutyl titanate and 50mL ethanol in a conical flask Mix and stir; (3) Take 2.5mL of the solution in (2) and add it to (1) to mix and stir to obtain a uniform core layer spinning solution;

[0032] B: Weigh 200mg of tin tetrachloride pentahydrate, 60mg of antimony trichloride, and 6g of polyvinylpyrrolidone and dissolve them in 40mL of N,N-dimethylformamide to obtain a uniform shell spinning solution;

[0033] C: Place the spinning solution prepared in steps A and B in an electrospinning device, spin coaxially, with a spinning voltage of 15kV, a spinning distance of 15cm, and a core layer spinning solution advancing speed of 0.2mL / h. The propulsion speed of the layer spinning solution is 0.1mL / h to obtain a non-woven fiber mat;

[0034] D: Place the fiber mat obtained in step C in a temperature-programmed muffle furnace, increase the tem...

Embodiment 3

[0036] A: Measure 16mL of ethanol, 4mL of acetic acid, 2mL of tetrabutyl titanate, and 2g of polyvinylpyrrolidone in a conical flask for mixing and stirring to obtain a uniform core layer spinning solution;

[0037] B: Weighing 100mg of tin tetrachloride pentahydrate, 30mg of antimony trichloride, and 2g of polyvinylpyrrolidone were dissolved in 16mL of ethanol and 4mL of acetic acid to obtain a uniform shell spinning solution;

[0038] C: Place the spinning solution prepared in step A and step B in the electrospinning equipment, spin coaxially, the spinning voltage is 15kV, the spinning distance is 15cm, the core layer spinning solution advances at a speed of 1mL / h, and the shell layer The propulsion speed of the spinning solution is 2.2mL / h to obtain a non-woven fiber mat;

[0039] D: Place the fiber mat obtained in step C in a temperature-programmed muffle furnace, increase the temperature at a rate of 4°C / min, raise the temperature to 600°C, and calcinate for 8 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com