Antimony/nitrogen-doped carbon compound by taking 1-ethyl-3-methylimidazole dicyanamide as carbon source, and preparation method and application thereof

A technology of methyl imidazole dicyandiamide and nitrogen-doped carbon, which is applied in the field of electrode materials, can solve the problems of volume change of antimony, poor cycle stability, loss of electrical contact, etc., and achieves the effects of excellent electrochemical performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of antimony / nitrogen doped carbon composites

[0021] 400 mg of antimony trichloride was weighed and dissolved in 5 mL of methanol to form a clear solution, which was named solution A. Solution B was obtained by dissolving 500 mg of 1-ethyl-3-methylimidazolium dicyanamide ionic liquid in 5 mL of methanol. Pour solution B into solution A under vigorous stirring, and stop stirring after obtaining a uniform solution. After standing for 12 h, the white solid was collected by centrifugation, washed with methanol and centrifuged 5 times. Subsequently, the resulting product was placed in a porcelain boat and transferred to a tube furnace at H 2 / Ar (5:95 v / v) atmosphere, the temperature was raised to 600 °C at a rate of 5 °C / min, and then kept at 600 °C for 2 h to obtain a black antimony / nitrogen-doped carbon composite (Sb@NC).

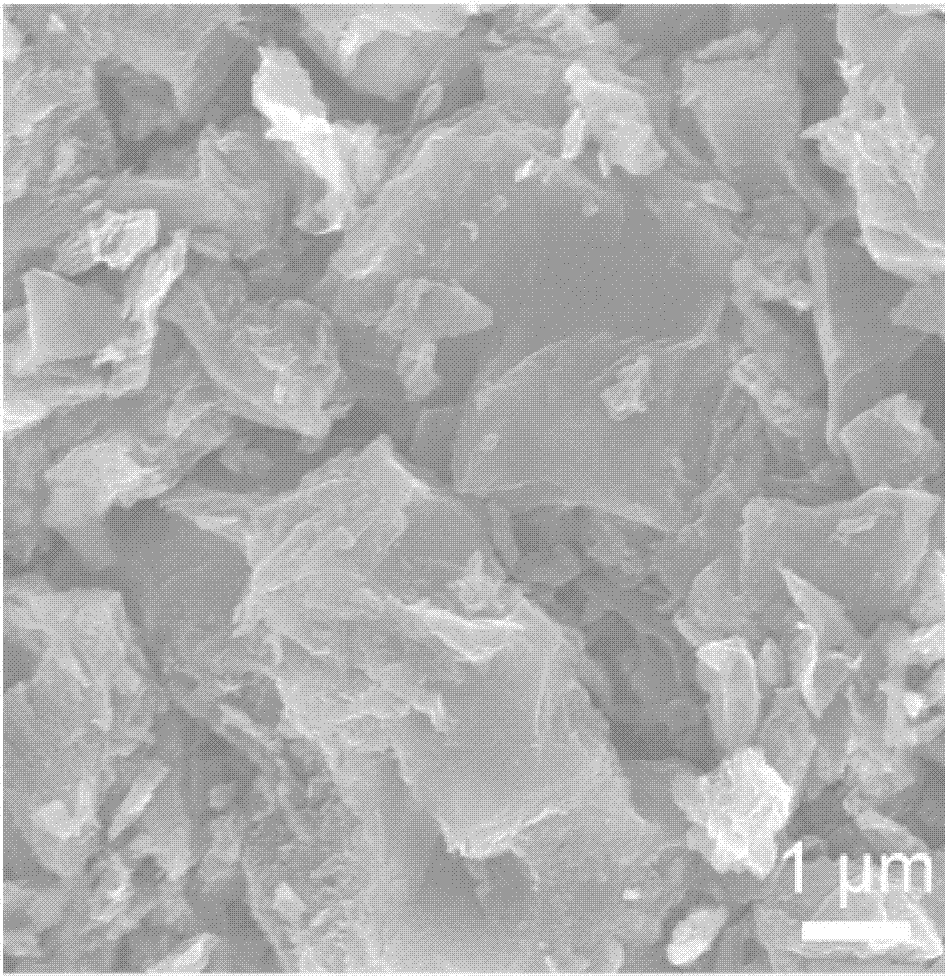

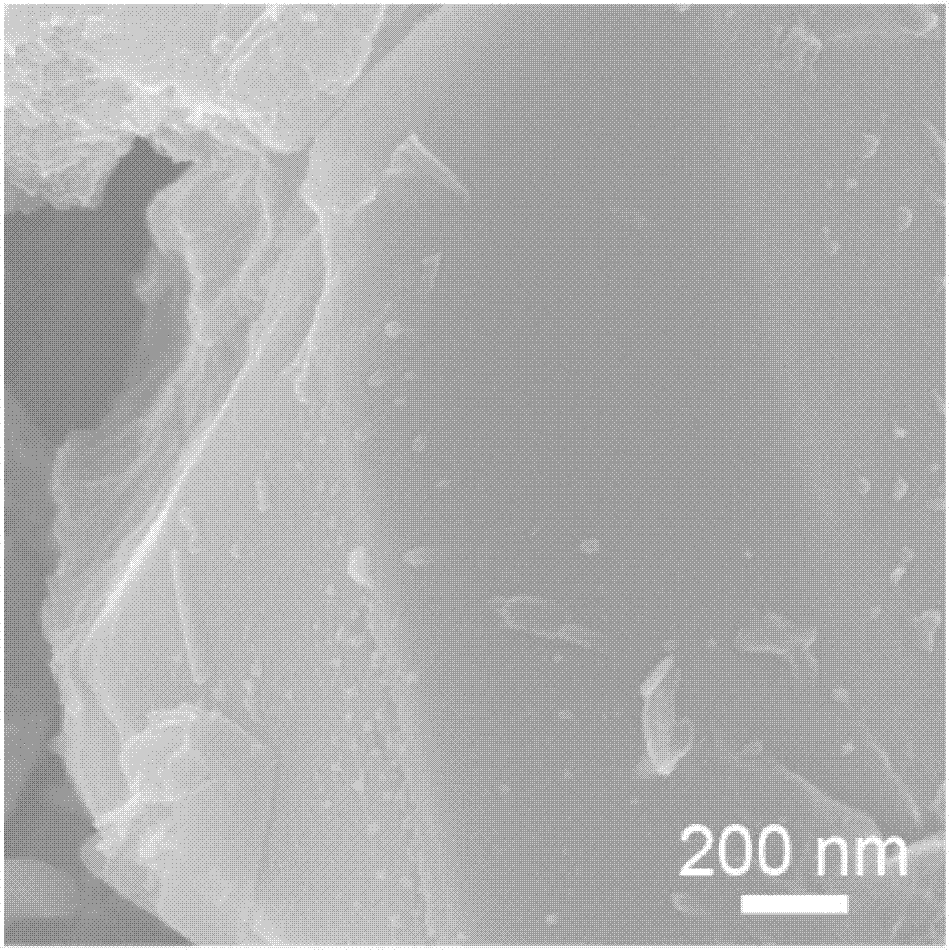

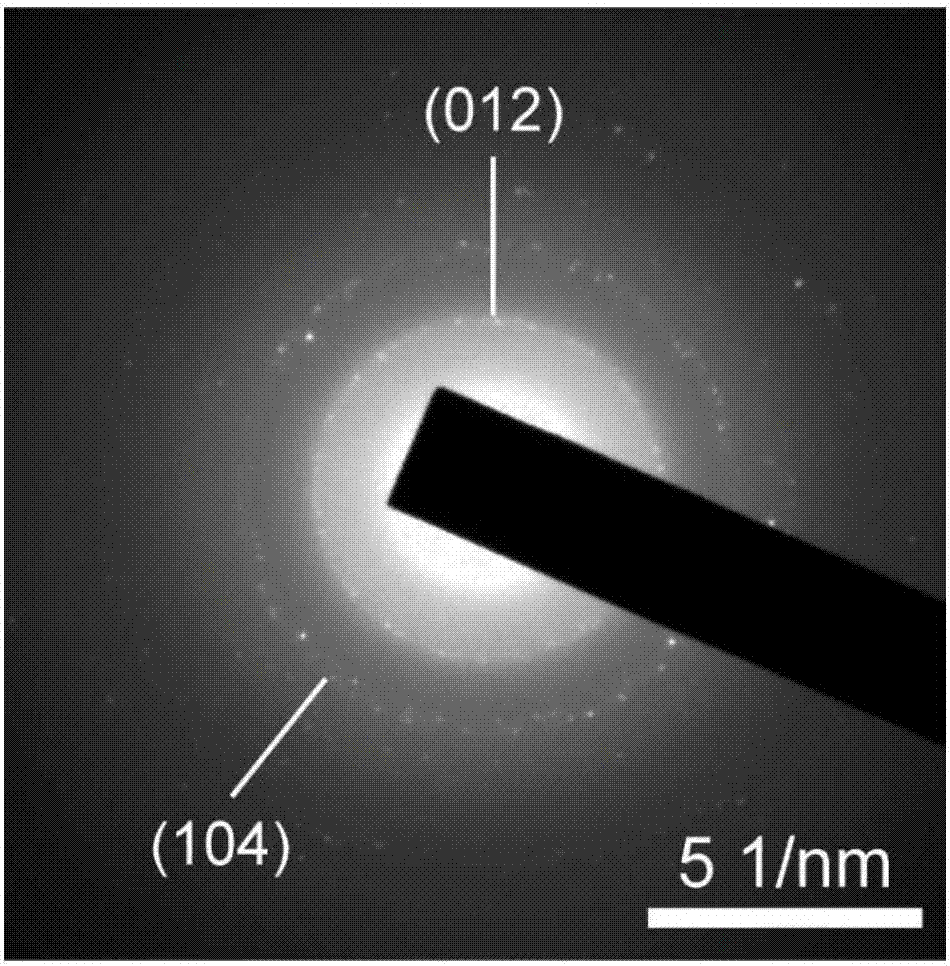

[0022] (2) Characterization of antimony / nitrogen-doped carbon composites

[0023] The size, morphology and microstructure of the ...

Embodiment 2

[0065] Weigh 400 mg of antimony trichloride and dissolve in 5 mL of methanol to form a clear solution, which is named solution A. 500 mg of 1-ethyl-3-methylimidazolium dicyanamide ionic liquid was dissolved in 5 mL of methanol to obtain solution B. Pour solution B into solution A under vigorous stirring, and stop stirring after obtaining a uniform dispersion. After standing for 12 h, the white solid was collected by centrifugation, washed with methanol and centrifuged 5 times. Subsequently, the resulting product was transferred into a porcelain boat and transferred to a tube furnace at H 2 / Ar (10:90v / v) atmosphere, the temperature was raised to 600°C at a rate of 5°C / min, and then kept at 600°C for 4h to obtain a black antimony / nitrogen-doped carbon composite.

[0066] The structural characterization and electrochemical performance test of the prepared antimony / nitrogen-doped carbon composite were carried out in the same manner as in Example 1, and the results were basicall...

Embodiment 3

[0068] Weigh 450 mg of antimony trichloride and dissolve in 5 mL of methanol to form a clear solution, which is named solution A. Solution B was obtained by dissolving 500 mg of 1-ethyl-3-methylimidazolium dicyanamide ionic liquid in 5 mL of methanol. Pour solution B into solution A under vigorous stirring, and stop stirring after obtaining a uniform dispersion. After standing for 15 h, the white solid was collected by centrifugation, washed with methanol and centrifuged 5 times. Subsequently, the resulting product was placed in a porcelain boat and transferred to a tube furnace at H 2 / Ar (5:95v / v) atmosphere, the temperature was raised to 600°C at a rate of 5°C / min, and then kept at 600°C for 2h to obtain a black antimony / nitrogen-doped carbon composite.

[0069] The structural characterization and electrochemical performance test of the prepared antimony / nitrogen-doped carbon composite were carried out in the same manner as in Example 1, and the results were basically the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com