Heat-insulating coating and preparation method thereof

A heat-insulating coating and heat-insulating material technology, applied in coatings, chemical instruments and methods, reflective/signal coatings, etc., to achieve the effects of reducing heat transfer, good weather resistance, and excellent heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

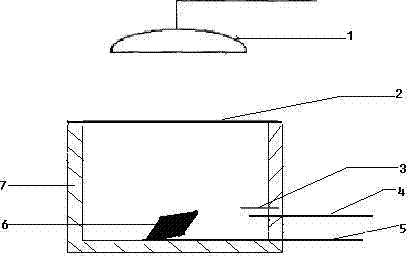

Image

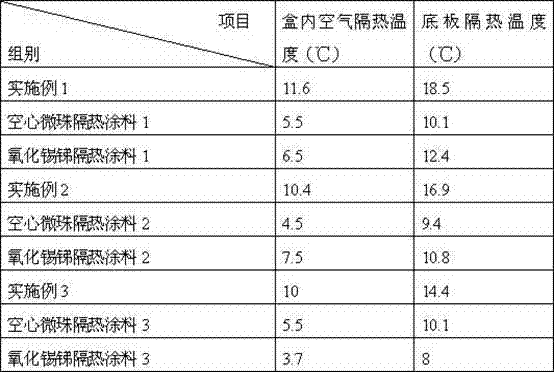

Examples

Embodiment 1

[0033] (1) 1.766g (0.005mol) SnC1 4 ·5H 2 O is dissolved in 100ml distilled water, the concentration of the prepared tin tetrachloride solution is 0.05mol / L, the prepared tin tetrachloride solution and 3g 1800 mesh hollow microspheres are added in the 250ml four-necked flask, the hollow microspheres use Soak in distilled water and ultrasonically disperse for 20min, place the flask in a constant temperature water bath at 60°C, stir continuously with an electric stirrer at 300rpm / min, add 1:1 ammonia water dropwise at an average speed of 6ml / min until the pH value is 3, then stop stirring , continue to keep warm for 3h to obtain seed crystals;

[0034] (2) 0.575g (0.0025mol) SbCl 3 and 8.83 g (0.025 mol) of SnC1 4 ·5H 2 O was dissolved in 100ml of absolute ethanol, and 1.5ml of 37% concentrated hydrochloric acid was first added to the ethanol to inhibit the hydrolysis of ions, and Sb 3+ / Sn 4+ The ratio of the amount of substances is 1:10 to obtain a mixed solution of ...

Embodiment 2

[0039] (1) 1.766g (0.005mol) SnC1 4 ·5H 2 O is dissolved in 200ml distilled water, the concentration of the prepared tin tetrachloride solution is 0.025mol / L, the prepared tin tetrachloride solution and 0.5g 1800 mesh hollow microspheres are added in the 250ml four-necked flask, the hollow microspheres Soak in distilled water before use, and ultrasonically disperse for 20min, place the flask in a constant temperature water bath at 60°C, stir continuously with an electric stirrer at 300rpm / min, slowly add 1:1 ammonia water dropwise at a speed of 6ml / min until the pH value is 3, then Stop stirring, continue to insulate for 3h, obtain crystal seed;

[0040] (2) 0.8615g (0.00378mol) SbCl 3 and 8.83 g (0.025 mol) of SnC1 4 ·5H 2 O was dissolved in 100ml of absolute ethanol, and 2ml of 37% concentrated hydrochloric acid was added to the ethanol to inhibit the hydrolysis of ions, and Sb 3+ / Sn 4+ The ratio of the amount of substances is 1:6.67, and the mixed solution of antimon...

Embodiment 3

[0045] (1) 1.766g (0.005mol) SnC1 4 ·5H 2 O is dissolved in 50ml distilled water, the concentration of the prepared tin tetrachloride solution is 0.1mol / L, the prepared tin tetrachloride solution and 5g 1800 mesh hollow microspheres are added in the 250ml four-necked flask, the hollow microspheres use Soak in distilled water and ultrasonically disperse for 20 minutes, place the flask in a constant temperature water bath at 60°C, stir continuously with an electric stirrer at 300rpm / min, slowly add 1:1 ammonia water dropwise at a rate of 6ml / min until the pH value is 3, then stop Stir and continue to insulate for 3h to obtain seed crystals;

[0046] (2) 0.2875g (0.00125mol) SbCl 3 and 8.83 g (0.025 mol) of SnC1 4 ·5H 2 O was dissolved in 100ml of absolute ethanol, and 1ml of 37% concentrated hydrochloric acid was added to the ethanol to inhibit the hydrolysis of ions, and Sb 3+ / Sn 4+ The ratio of the amount of substances is 1:20, to obtain a mixed solution of antimony tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com