Precursor solution for preparing semiconductor electro-thermal film, electro-thermal film and preparation method of electro-thermal film

A technology of precursor solution and electric heating film, which is applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of insufficient stability of film formation, insufficient ability to withstand thermal stress, easy cracking or falling off, etc., to promote heat resistance Capability of impact and thermal stress, great market promotion prospect, effect of shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

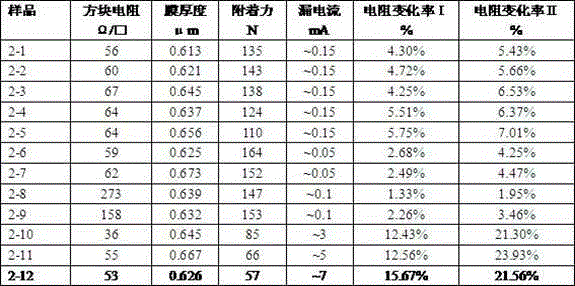

Examples

Embodiment 1-1

[0067] The configuration of the precursor solution of the prepared semiconductor electrothermal film includes by weight parts:

[0068] Tin tetrachloride 40

[0069] Nano tin dioxide 15

[0070] Antimony trichloride 3

[0071] Hydrofluoric acid 2.5

[0072] Boric acid 1.8

[0074] Triethanolamine 0.5

[0075] ethanol 50

[0076] Wherein, the nano tin dioxide is amorphous tin dioxide particles with an average particle diameter of 20nm.

Embodiment 1-2

[0078] The configuration of the precursor solution of the prepared semiconductor electrothermal film is the same as that of Example 1-1 in terms of parts by weight.

[0079] The difference is that the nano-tin dioxide is amorphous tin dioxide particles with an average particle diameter of 50nm.

Embodiment 1-3

[0081] The configuration of the precursor solution of the prepared semiconductor electrothermal film is the same as that of Example 1-1 in terms of parts by weight.

[0082] The difference is that the nano tin dioxide is amorphous tin dioxide particles with an average particle diameter of 100nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com