Preparation method of zinc oxide/antimony tin oxide composite nano-material

A technology of composite nanomaterials and tin antimony oxide, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of easy recombination and loss of catalysis problems such as activity, to achieve the effect of easy operation control, low preparation cost and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

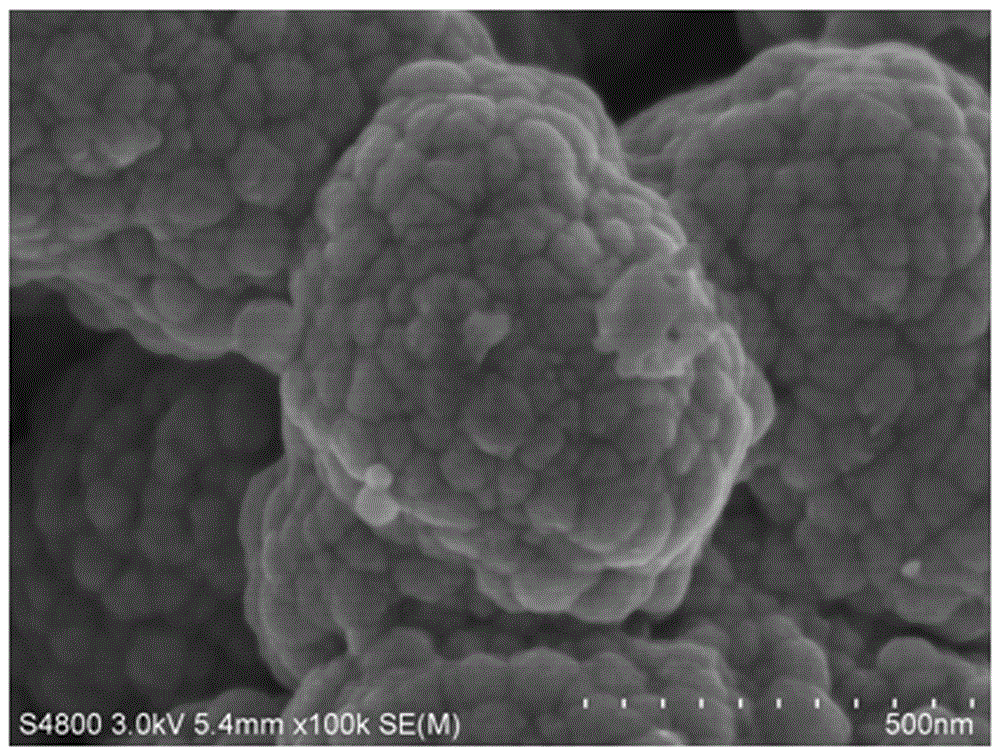

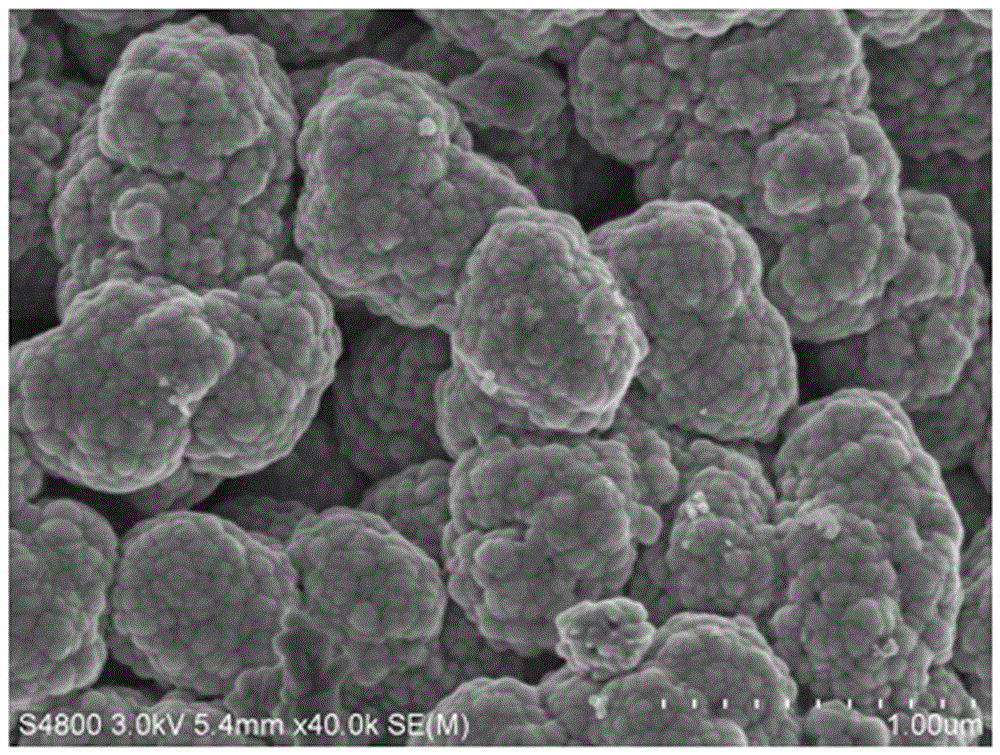

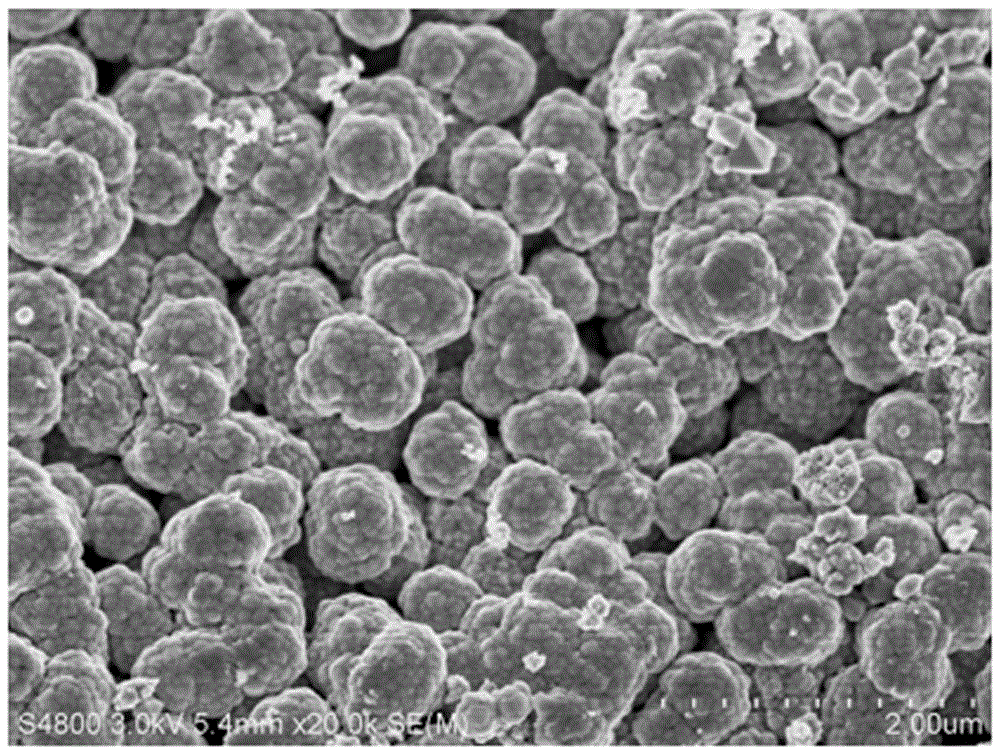

Embodiment 1

[0034] Slowly add the isopropanol solution with a concentration of 0.1 mol / L zinc acetylacetonate into the DMF solution with a concentration of 0.1 mol / L tin tetrachloride and antimony trichloride, and mix well. Wherein the molar ratio of zinc acetylacetonate and tin tetrachloride is 9:0.9. The obtained mixed solution was subjected to a cross-linking reaction, the reaction temperature was 150° C., and the reaction time was 8 hours. Wherein, the molar concentration of the DMF mixed solution of tin tetrachloride and antimony trichloride is 0.1 mol / L, and the molar ratio of tin tetrachloride and antimony trichloride is 9:2. After the cross-linking reaction, the high-temperature reaction was carried out in the muffle furnace. The high-temperature reaction temperature was 800 °C and the reaction time was 6 h. After natural cooling, the target product is obtained.

[0035] The band gap of the product is 2.5 eV. The yield of its product is 99.5%. The purity of the product is not ...

Embodiment 2

[0037] The methanol solution with a concentration of 0.1 mol / L zinc acetylacetonate was slowly added dropwise to the DMF solution with a concentration of 0.1 mol / L tin tetrachloride and antimony trichloride, and mixed well. Wherein the molar ratio of zinc acetylacetonate and tin tetrachloride is 9:1.8. The obtained mixed solution was subjected to cross-linking reaction, the reaction temperature was 400° C., and the reaction time was 2 hours. Wherein, the molar concentration of the DMF mixed solution of tin tetrachloride and antimony trichloride is 0.1 mol / L, and the molar ratio of tin tetrachloride and antimony trichloride is 9:2. After the cross-linking reaction, the high-temperature reaction was carried out in the muffle furnace. The high-temperature reaction temperature was 500 °C and the reaction time was 24 h. After natural cooling, the target product is obtained.

[0038] The band gap of the product is 2.6 eV. The yield of its product is 99.3%. The product purity is ...

Embodiment 3

[0040] Slowly add the ethylene glycol solution with a concentration of 0.05 mol / L zinc acetylacetonate into the DMF solution with a concentration of 0.05 mol / L tin tetrachloride and antimony trichloride, and mix well. Wherein the molar ratio of zinc acetylacetonate and tin tetrachloride is 9:3.6. The obtained mixed solution was subjected to cross-linking reaction, the reaction temperature was 400° C., and the reaction time was 6 hours. Wherein, the molar concentration of the DMF mixed solution of tin tetrachloride and antimony trichloride is 0.05 mol / L, and the molar ratio of tin tetrachloride and antimony trichloride is 9:2. After the cross-linking reaction, the high-temperature reaction was carried out in the muffle furnace. The high-temperature reaction temperature was 600 °C and the reaction time was 12 h. After natural cooling, the target product is obtained.

[0041] The band gap of the product is 2.7 eV. The yield of its product is 98.0%. The product purity is not l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com