Method for preparing Sb2O3/carbon felt flexible sodium ion battery anode material

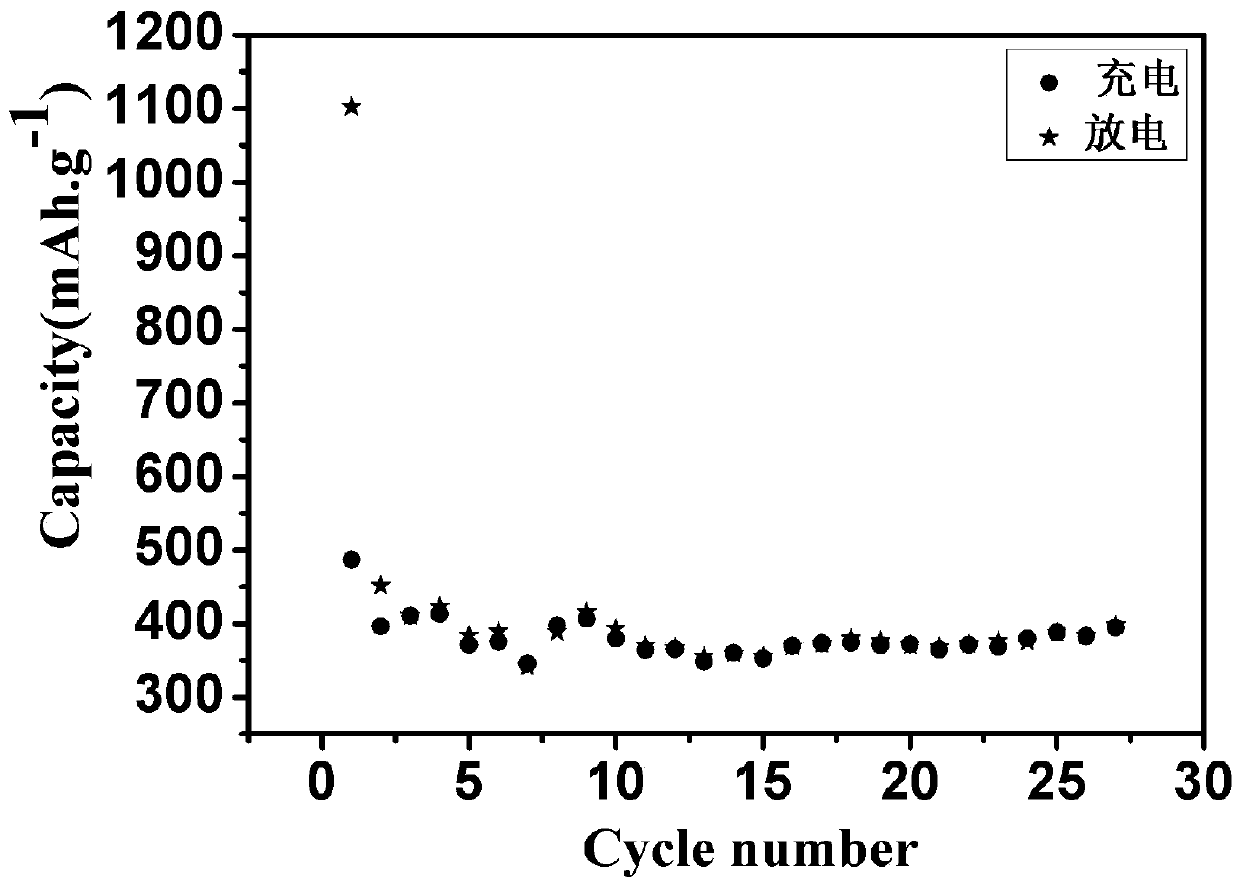

A sodium-ion battery and negative electrode material technology, applied in the direction of electrode manufacturing, battery electrode, chemical electrode manufacturing, etc., can solve the problems of complex process and high cost of raw materials, and achieve simple process, high repeatability, and stable electrochemical cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

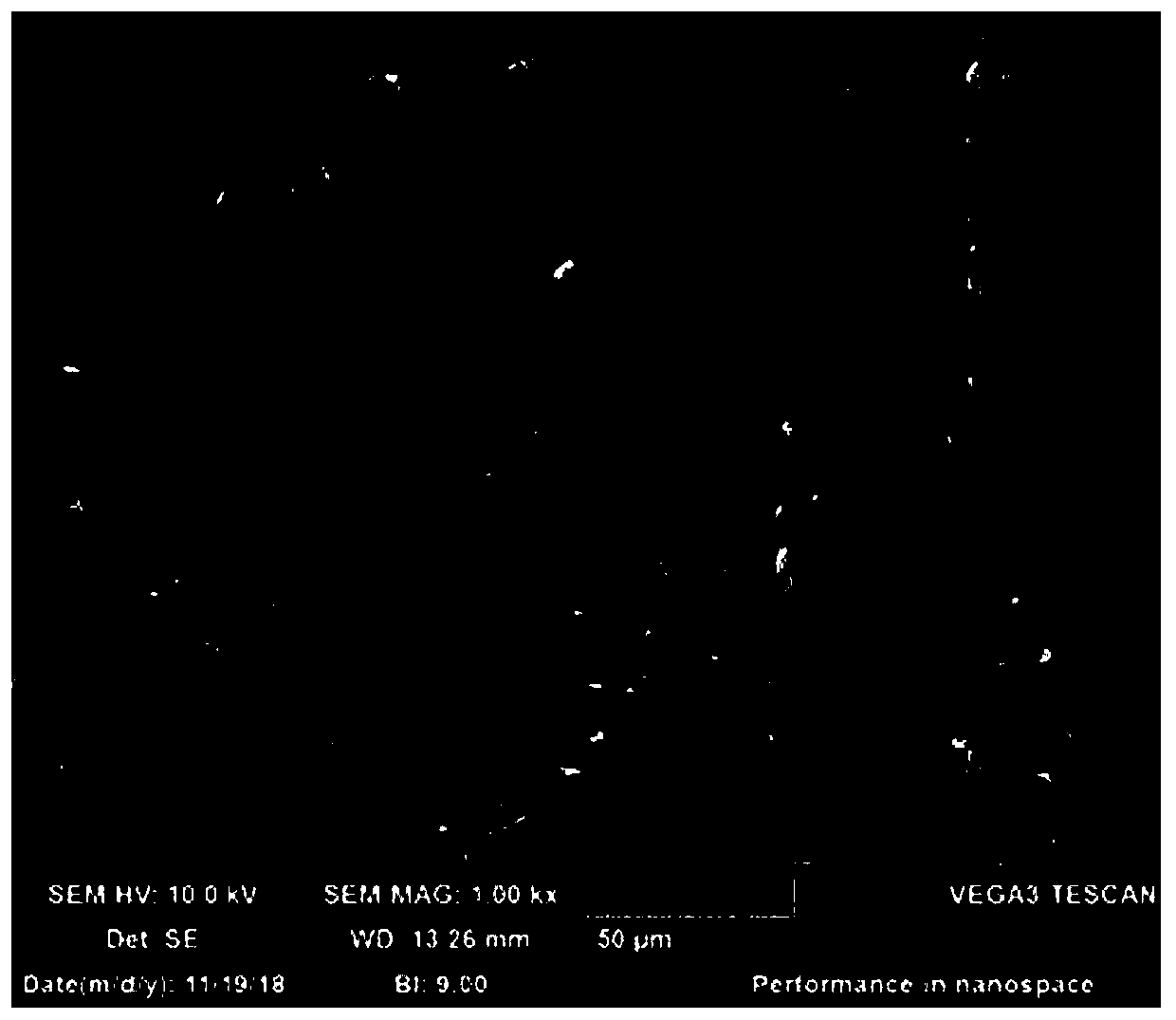

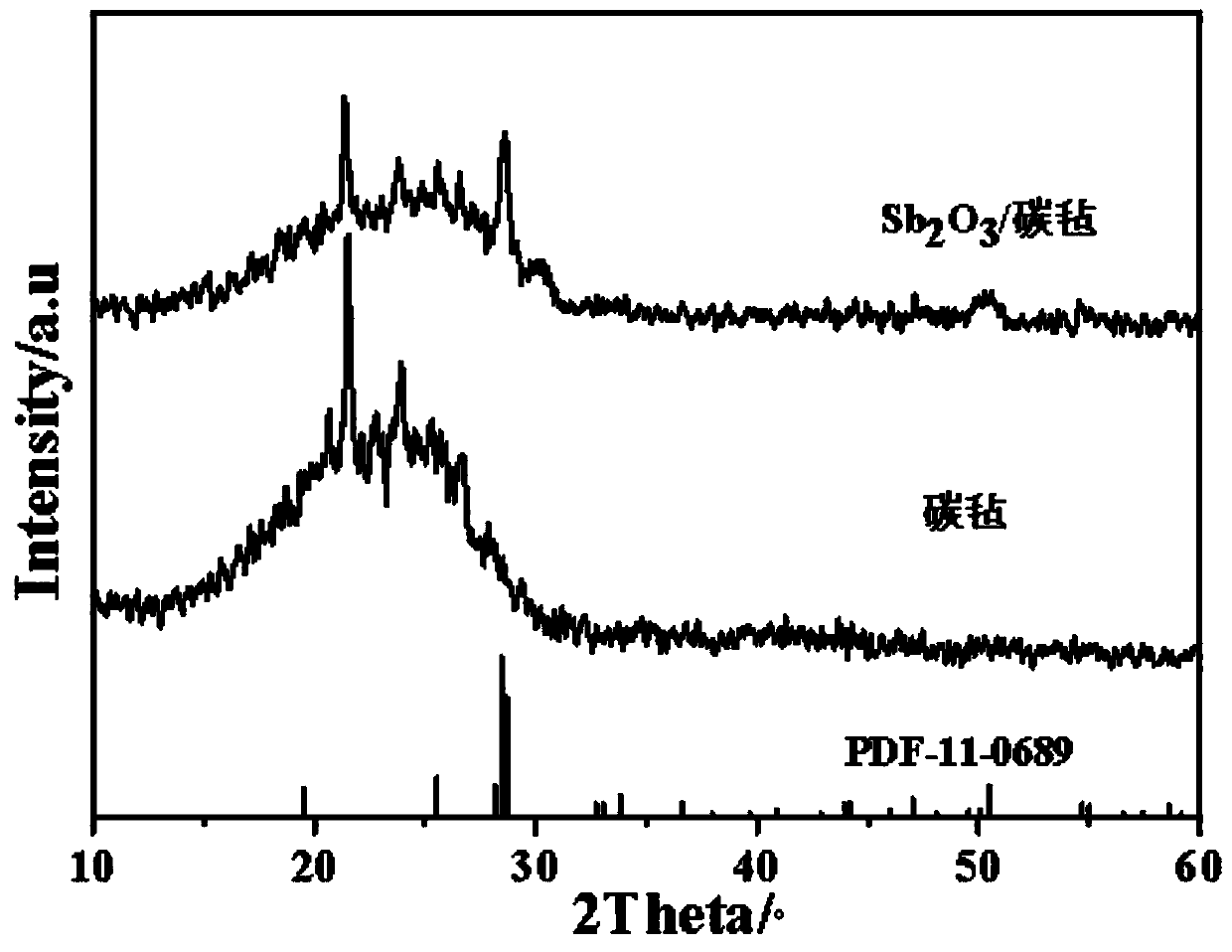

[0027] a Sb 2 o 3 The preparation method of carbon felt flexible sodium ion battery negative electrode material, comprises the following steps:

[0028] Step 1: Put the HM-20 carbon felt with a length of 4 cm and a width of 2 cm into 50 mL of acetone and soak for 24 hours to remove surface impurities, then clean it with deionized water and absolute ethanol, and place the cleaned carbon felt in an oven for 60 Dry at ℃; use the dried carbon felt as the anode, the graphite plate as the cathode, and 20g / L ammonium dihydrogen phosphate aqueous solution as the electrolyte to anodize the carbon felt. The electrolysis voltage is 5V for 3 minutes; then the carbon felt Wash them with deionized water and absolute ethanol respectively, and dry them in an oven at 60°C for later use;

[0029] Step 2: Add 0.34 g of antimony trichloride to 20 ml of absolute ethanol and magnetically stir to obtain an antimony trichloride solution, add 0.3 g of sodium hydroxide to 5 ml of deionized water and ...

Embodiment 2

[0034] a Sb 2 o 3 The preparation method of carbon felt flexible sodium ion battery negative electrode material, comprises the following steps:

[0035]Step 1: Put the HM-20 carbon felt with a length of 4 cm and a width of 2 cm into 50 mL of acetone and soak for 72 hours to remove surface impurities, then clean it with deionized water and absolute ethanol respectively, and place the cleaned carbon felt in an oven Dry at 60°C. The dried carbon felt was used as the anode, the graphite plate was used as the cathode, and 20g / L ammonium dihydrogen phosphate aqueous solution was used as the electrolyte to anodize the carbon felt, and the electrolysis voltage was 5V for 5 minutes; Clean with absolute ethanol, put the carbon felt in an oven at 60°C and then dry it for later use;

[0036] Step 2: Add 0.46 g of antimony trichloride to 30 ml of absolute ethanol and magnetically stir to obtain an antimony trichloride solution, add 0.6 g of sodium hydroxide to 10 ml of deionized water a...

Embodiment 3

[0041] a Sb 2 o 3 The preparation method of carbon felt flexible sodium ion battery negative electrode material, comprises the following steps:

[0042] Step 1: Put the HM-20 carbon felt with a length of 4 cm and a width of 2 cm into 50 mL of acetone and soak for 72 hours to remove surface impurities, then clean it with deionized water and absolute ethanol respectively, and then place the carbon felt in an oven for 60 Dry at ℃. The dried carbon felt was used as the anode, the graphite plate was used as the cathode, and the carbon felt was anodized with 20g / L ammonium dihydrogen phosphate aqueous solution as the electrolyte, and the electrolysis voltage was 5V for 10 minutes; then the carbon felt was deionized with deionized Clean the water and absolute ethanol, place them in an oven at 60°C and dry them for later use;

[0043] Step 2: Add 0.57 g of antimony trichloride to 20 ml of absolute ethanol and magnetically stir to obtain an antimony trichloride solution, add 0.6 g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com