Preparation method of low-temperature sulfur-resistant and water-resistant denitration catalyst

A denitrification catalyst and catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of low-temperature industrial boiler flue gas treatment, complex equipment, poor low-temperature activity, etc. problems, to achieve the effect of abundant raw materials, low cost, and lower activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

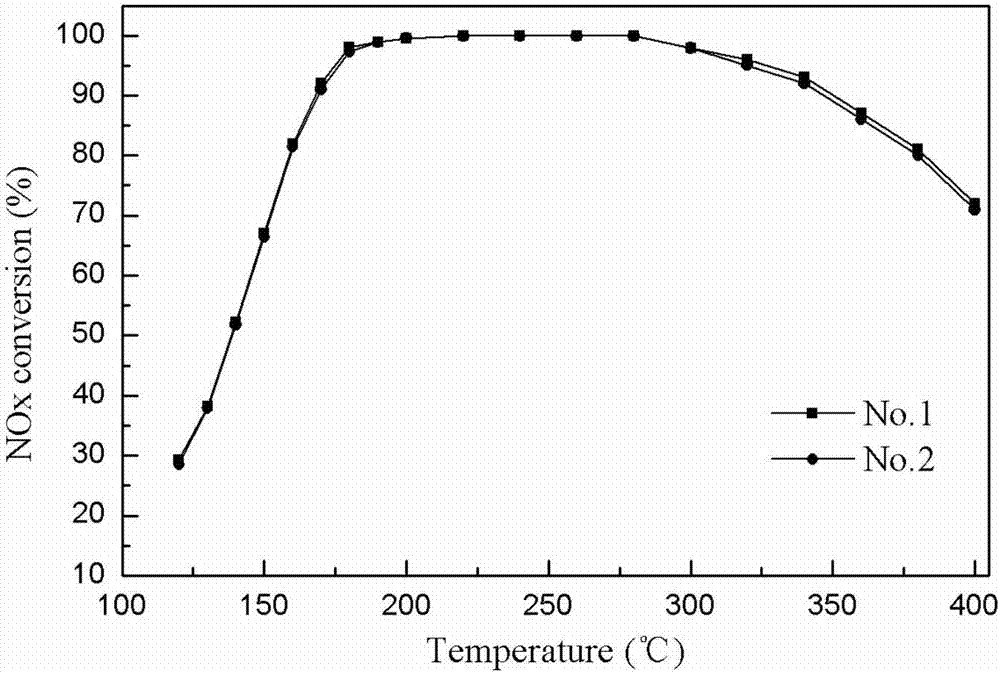

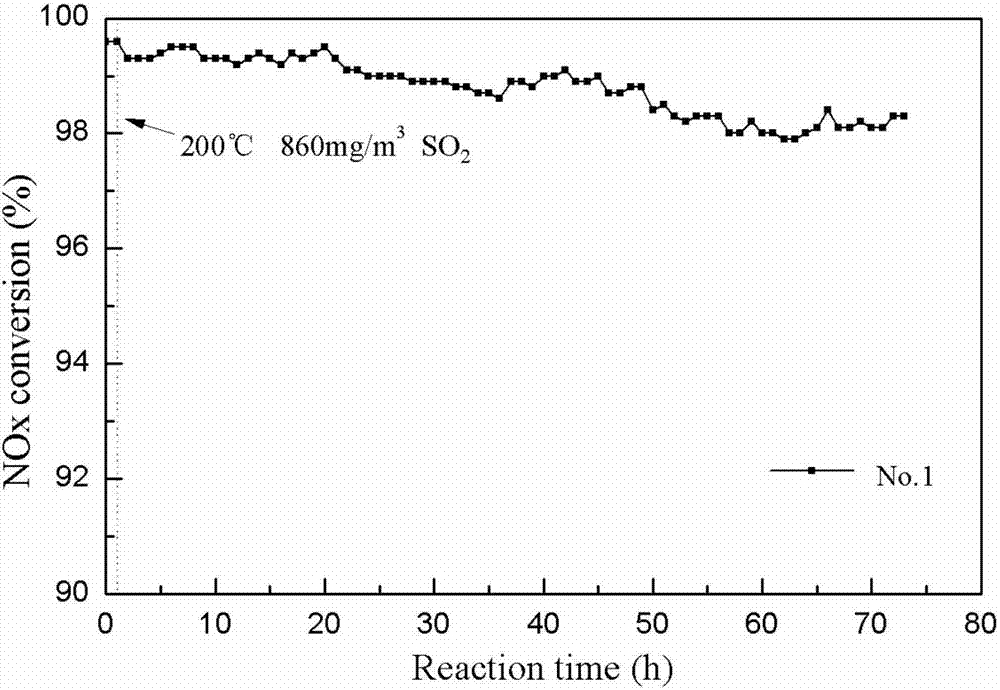

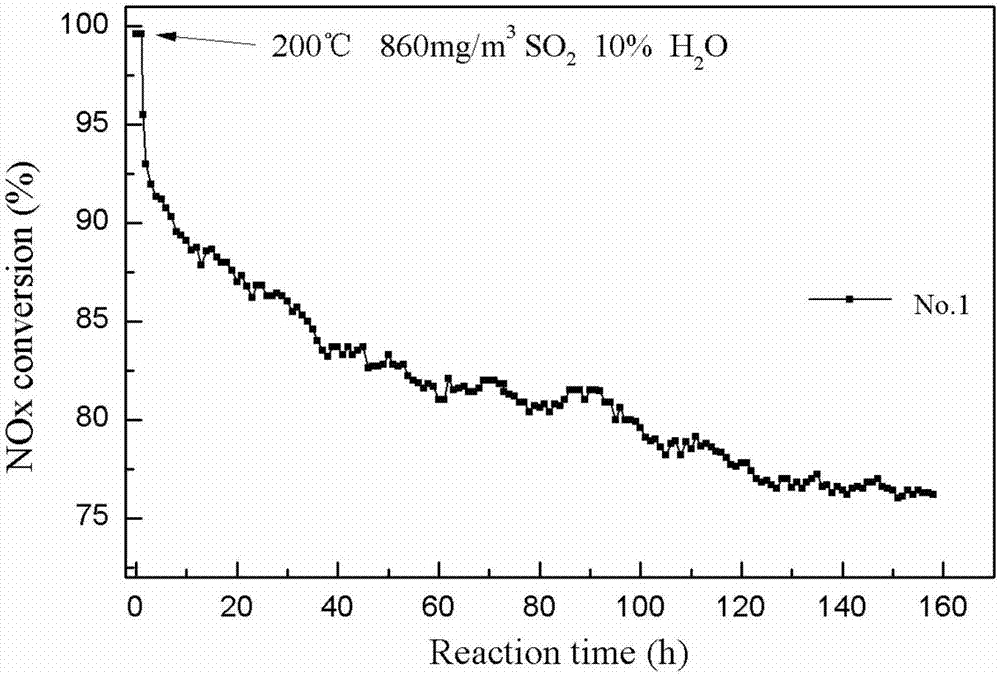

example 1

[0023] Dissolve 2g of oxalic acid, 1g of ammonium metavanadate and 3g of antimony trichloride in 40g of deionized water, and dissolve them all at 40°C; finally, 20g of TiO 2 Slowly add the carrier to the above solution, and make it viscous at 40°C; put the obtained viscous solid in an oven for drying, then put it in a muffle furnace, and make it viscous at 250°C Calcined for 2 hours, then calcined at 450°C for 5 hours, cooled naturally to room temperature, sieved to 20-120 mesh for later use, and obtained 1# catalyst.

example 2

[0025] Dissolve 6g of oxalic acid, 2g of ammonium metavanadate and 6g of antimony trichloride in 80g of deionized water, and dissolve them all at 40°C; finally, 40g of TiO 2 Slowly add the carrier to the above solution, and make it viscous at 40°C; put the obtained viscous solid in an oven for drying, then put it in a muffle furnace, and make it viscous at 250°C Calcined for 2 hours, then calcined at 450°C for 5 hours, cooled naturally to room temperature, sieved to 20-120 mesh for later use, and obtained 2# catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com