Manufacturing method of thermal column

A technology of heat column and heat transfer element is applied in the field of structure and manufacture of heat transfer element of high-power LED light source to achieve the effect of small thermal resistance and ensure normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

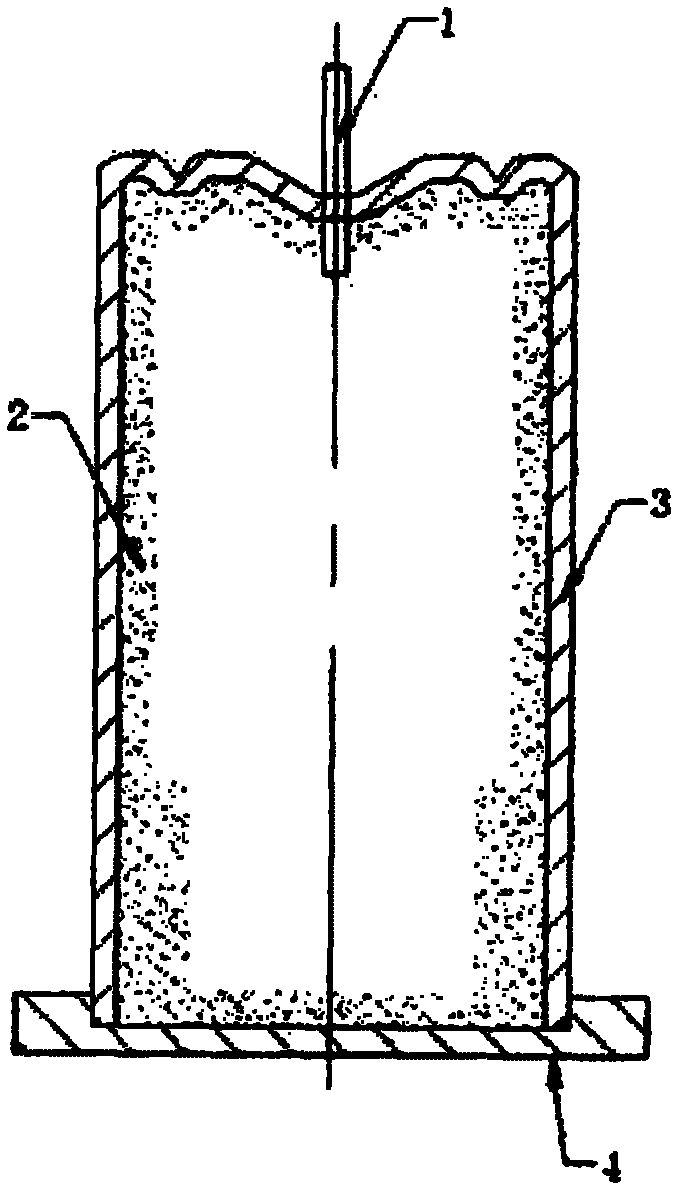

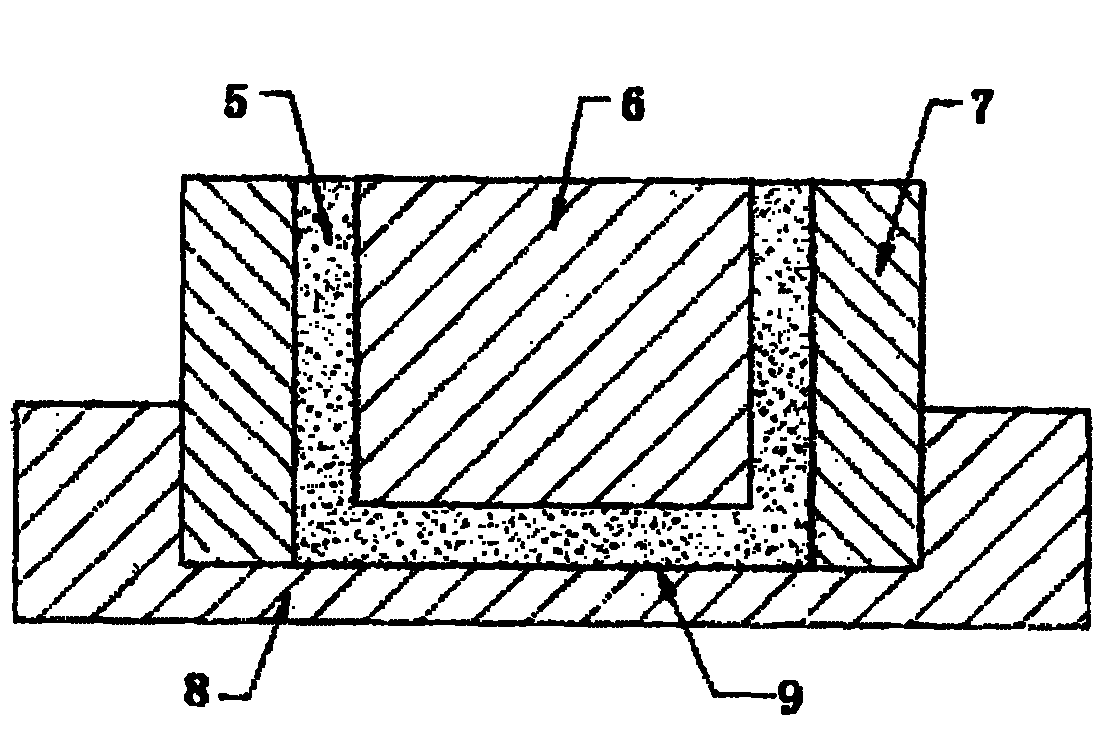

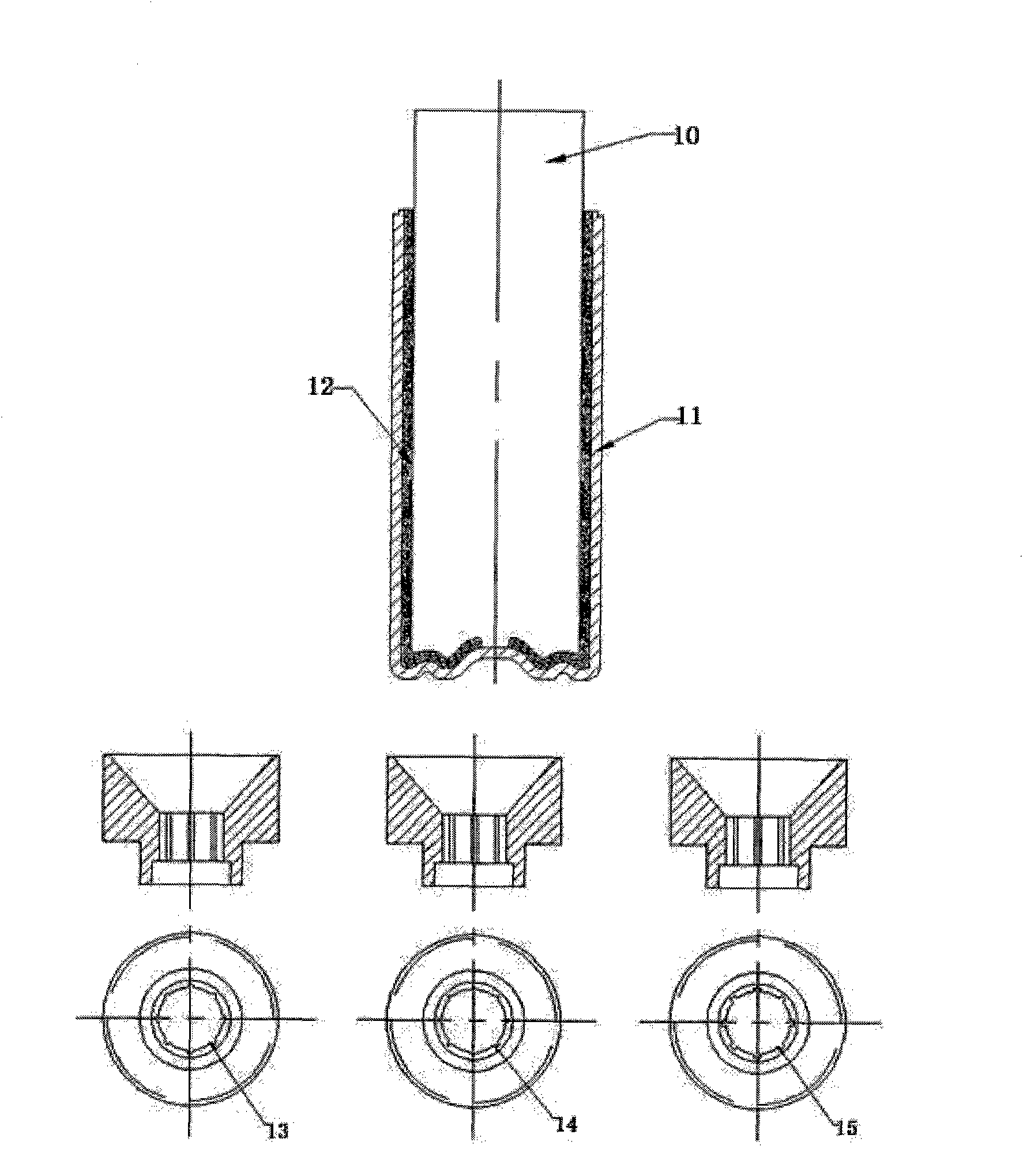

[0052] The method of assembling and welding hot column sintering is decomposed into sub-item sintering, assembly and then brazing. The thermal column body is put into the mandrel, and the electrolytic copper powder is vibrated into the interlayer through a special funnel for sintering. The evaporation section of the bottom plate is used The fixture is positioned and sintered to form a sintered copper powder layer that meets the required shape. The heat column body 2 is assembled with the base plate 1, so that the sintered layer on the base plate is embedded in the copper powder sintered layer of the tube body. The effect is that the sintered layers of each part of the heat column form a complete The connecting body is very conducive to the smooth circulation of the working fluid; a silver alloy welding wire ring is installed between the heat column tube body and the bottom plate, and a liquid injection and vacuuming small tube and a welding wire ring are placed in the φ2 hole in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com