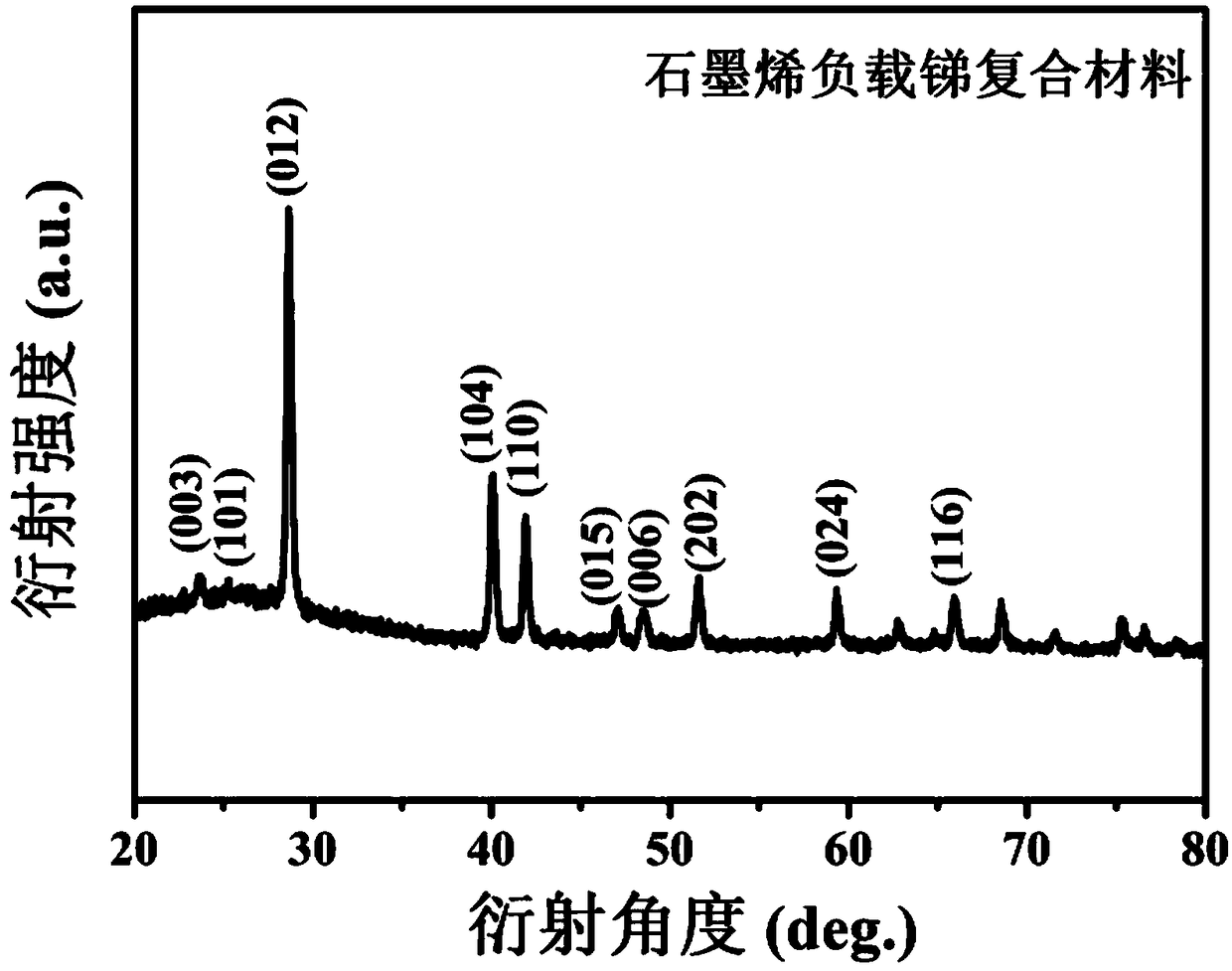

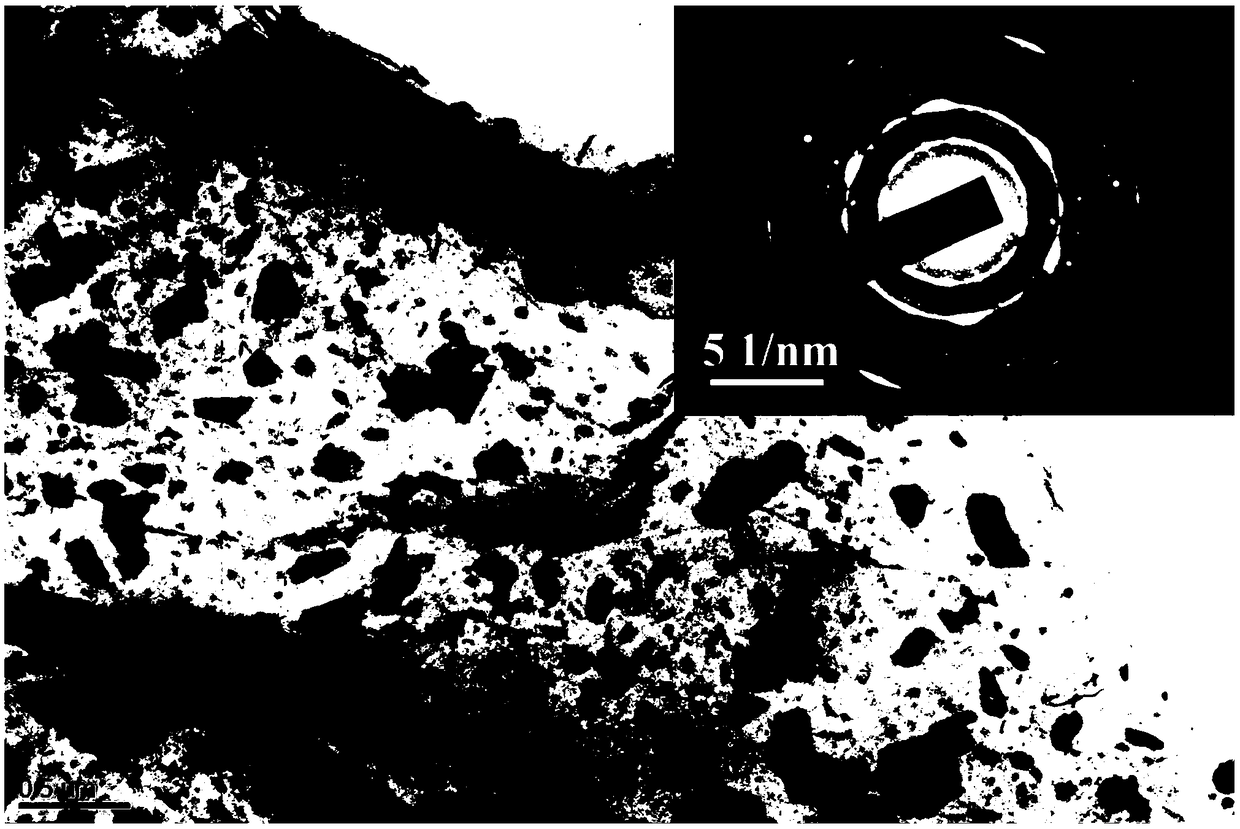

Reduced graphene oxide loaded antimony sodium-ion battery negative electrode material and preparation method thereof

A technology of sodium ion battery and negative electrode material, applied in the field of electrochemical energy storage, can solve the problems of battery capacity decay, easy pulverization of electrode materials, poor cycle performance, etc., and achieve the effects of excellent cycle rate performance, simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the sodium ion battery negative electrode material of reduced graphene oxide loaded with antimony:

[0030] Step 1: Preparation of graphene oxide.

[0031] Step 101. Weigh 10g flake graphite and 7.5g NaNO 3 In the beaker, slowly add 300ml of concentrated sulfuric acid (98%), and magnetically stir until uniform; slowly add 40g of potassium permanganate under magnetic stirring, and continue to stir for 96 hours to obtain a black gelatinous substance.

[0032]Step 102. Add 800ml of deionized water and 60ml of hydrogen peroxide (30%) to the black colloidal substance in turn, stir until uniform, and obtain a yellow solution; centrifuge the obtained yellow solution at 6000rpm at a high speed for 5 minutes to obtain a high-speed centrifuge Product; further preferably, the high-speed centrifugation process is repeated 3 to 5 times, and the high-speed centrifugation product is taken after washing with water until the supernatant is neutral.

[0033] S...

Embodiment 2

[0043] Preparation method of reduced graphene oxide loaded antimony negative electrode material:

[0044] Step 1: with embodiment 1.

[0045] Step 2: Weigh 2g of antimony trichloride in a glass bottle, add 10ml of ethanol dropwise, and obtain 10ml of 0.8M colorless and clear antimony trichloride ethanol solution after ultrasonication for 0.5h; Graphene oxide was dispersed in 40ml ethanol solution by ultrasound for 1h to obtain a dark brown solution; 0.18ml of ammonia water (25%) was added dropwise to the graphene oxide ethanol solution, and magnetically stirred for 3h; ml colorless and clear solution, connect the syringe to the extension tube, exhaust and check that there are no bubbles, fix it on the syringe pump fixing plug, start the syringe pump, add the colorless and clear solution dropwise at a flow rate of 0.1mL / min, and continue to stir for 12h. Obtain a dark gray solution; centrifuge the dark gray solution at 8500rpm for 8min and dry the precipitate at 80°C for 10h t...

Embodiment 3

[0050] Step 1: Graphene oxide preparation:

[0051] Take 8g of flake graphite and weigh NaNO according to the mass ratio of 4:3 3 , the two are mixed in a beaker, and slowly add 200ml of concentrated sulfuric acid (mass percentage concentration is 98%) in the beaker, and magnetically stir until uniform;

[0052] Slowly add 30g potassium permanganate under magnetic stirring condition, and continue to stir for 96 hours, obtain black colloidal substance; In black colloidal substance, add 800ml deionized water and 70ml hydrogen peroxide (the mass percent concentration of hydrogen peroxide is 30%) successively, Stir until uniform to obtain a yellow solution;

[0053] Centrifuge the obtained yellow solution at high speed, and wash with water until the supernatant is neutral; add the high-speed centrifuged product to deionized water again and stir evenly, after ultrasonic treatment, place it in a centrifuge, centrifuge at low speed, and collect the gray-brown viscous liquid in the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com