Electrode and preparation method of electrode material

An electrode material and electrode technology, applied in electrode manufacturing, battery electrodes, electrode heat treatment, etc., can solve problems such as the deterioration of aluminum battery cycle characteristics, achieve broad market promotion and implementation prospects, rapid ion mobility, and improve electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

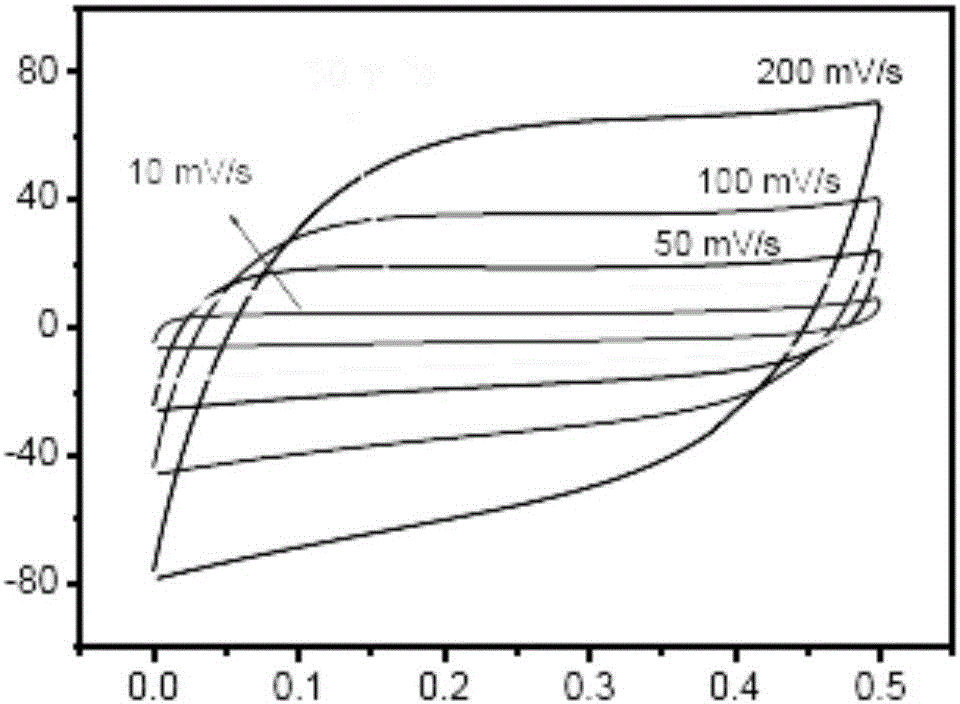

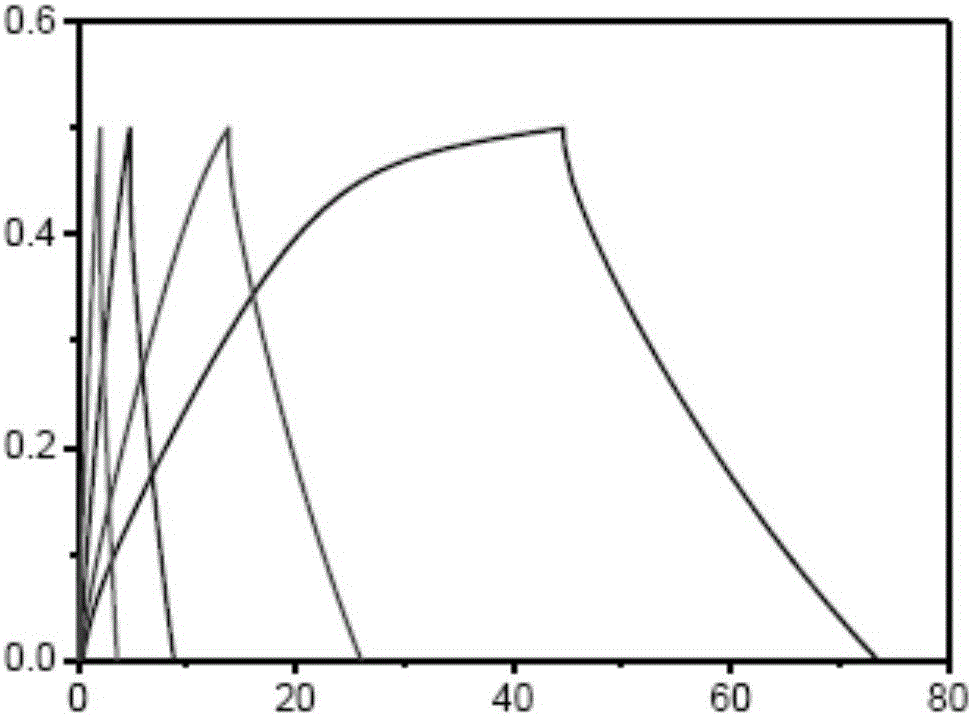

[0016] A kind of preparation method of electrode material that the present invention proposes, comprises the steps: (1) after the cigarette filter tip that is made by acetate fiber is removed wrapping paper, fully immerse in deionized water (general soaking 2-4 days), ultrasonic cleaning 26- 12 hours, dry and stand-by; (2) put the dried filter tip into vanadium dichloride VCl 2 , lead dichloride PbCl 2 , Tungsten dichloride WCl 2 and nickel dichloride NiCl 2 One of the solutions, or at least two of them mixed in any ratio, the solution concentration is 3wt% to 5wt%, and it is soaked in the above solution for 60-120 minutes in an ultrasonic vibration environment; (3) from the above The filter tip is taken out from the solution, dried, and subjected to high-temperature carbonization treatment to obtain carbonized composite material powder. The carbonized composite material powder is a material that can be used to make electrodes.

[0017] Among them, in the process of high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com