PVC battery separation plate production method and PVC battery separation plate

A battery separator and production method technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of poor wettability of electrolyte, difficult to manufacture, battery self-discharge, etc., and achieve good penetration resistance and recovery. Elasticity, effect of small pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

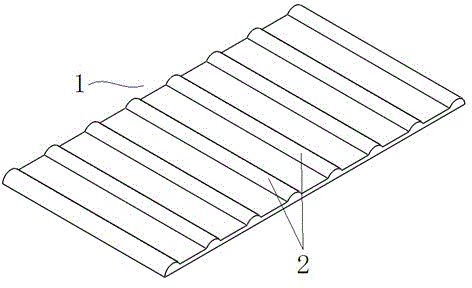

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0027] The present invention provides a kind of production method of PVC battery separator, and the method step comprises:

[0028] In the first step, polyvinyl chloride resin is mixed with plasticizer and then mixed with silica toner at high speed to form a mixture;

[0029] The second step is to add a solvent to the mixture, so that the solvent material is completely absorbed into the mixture to form a wet powder mixture;

[0030] The third step is to transport the mixture in wet powder state to the extruder for low temperature extrusion;

[0031] The fourth step is to emboss the mud material coming out of the die of the extruder on the calender to form the initial state partition;

[0032] The fifth step is to put the initial state separator into the extraction tank to extract the aforementioned solvent to form a microporous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com