Application of ruthenium palladium/carbon catalyst

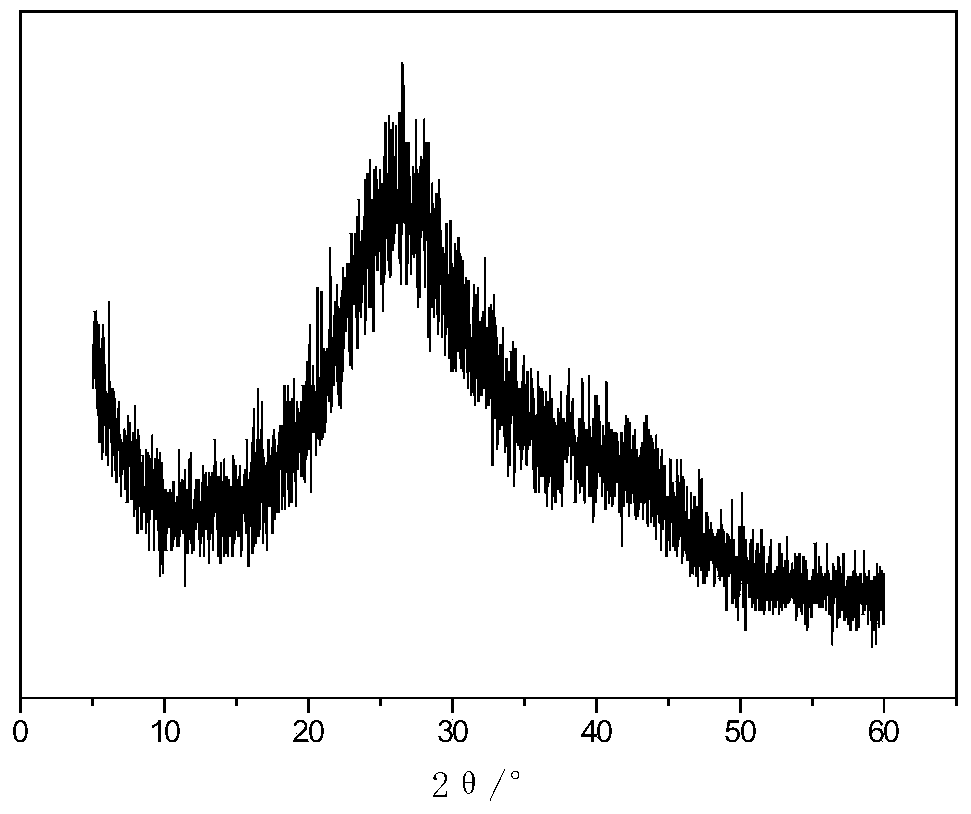

A carbon catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, heterogeneous catalyst chemical elements, metal/metal oxide/metal hydroxide catalysts, etc., can solve uneconomical production, high hydrogenation operating pressure, etc. problems, to achieve the effects of no three wastes discharge, improved surface properties, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

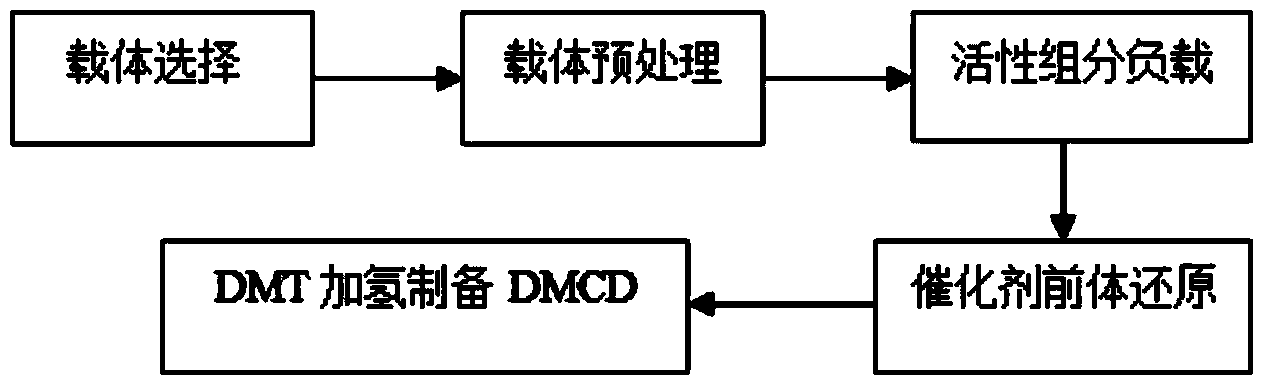

Method used

Image

Examples

Embodiment 1

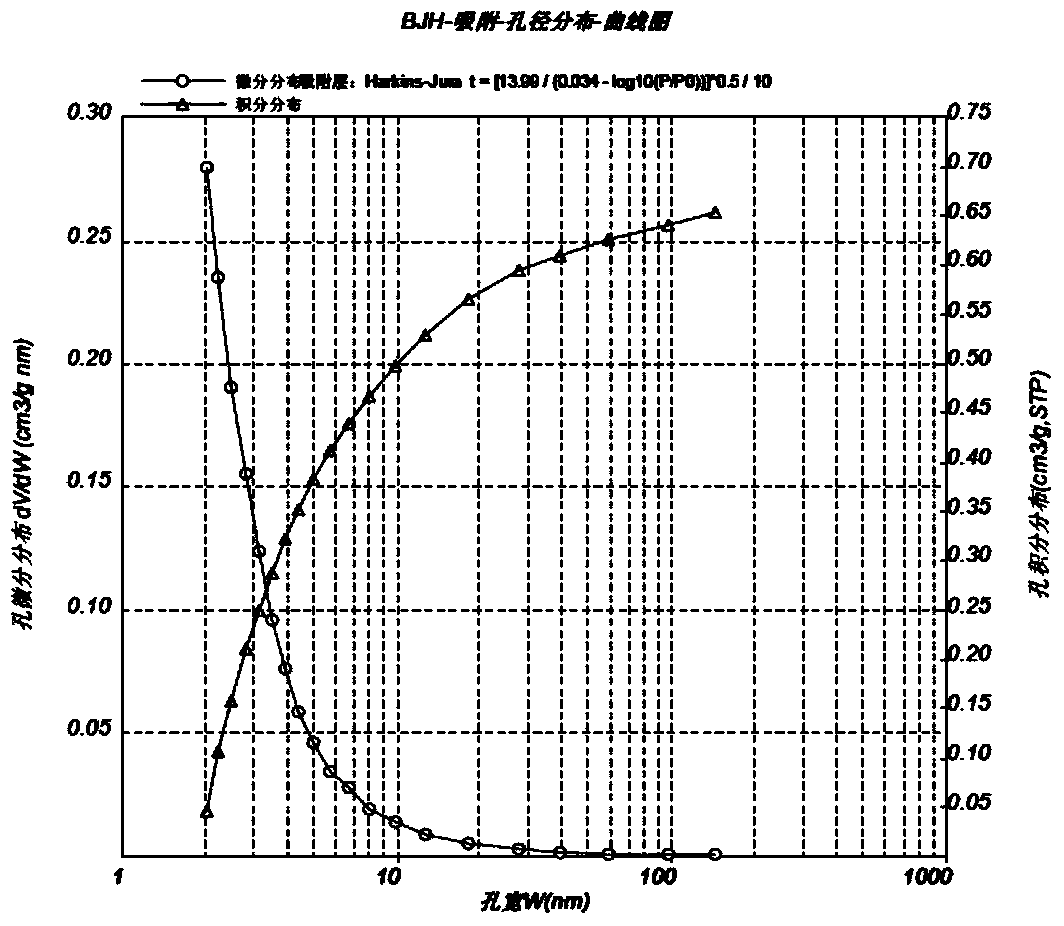

[0045] (1) Take 20g of self-made mesoporous carbon as the carrier material, place it in 80ml of 5mol / L nitric acid aqueous solution, immerse in a water bath at 80°C for 12h, cool, filter, wash with water until neutral, and dry; Lower degassing treatment for 2h;

[0046] (2) be 5.00% by active component ruthenium load capacity, palladium load capacity be 0.05% configure the ruthenium chloride solution of 3mol / L and the palladium chloride solution of 1.0mol / L respectively;

[0047] (3) The acid-treated mesoporous carbon was impregnated with ruthenium solution for 4 hours by vacuum equivalent impregnation method, dried at 80°C for 4 hours, and dried at 120°C for 6 hours; impregnated with palladium solution by the same method, stood in a water bath at 80°C for 4 hours, and dried at 80°C Dry 4h, obtain ruthenium palladium-carbon catalyst precursor;

[0048] (4) Use 10wt% NaOH aqueous solution to adjust the pH value to 11-12, precipitate for 2h, and let stand for 2h;

[0049] (5) ...

Embodiment 2

[0053] The same method as in Example 1 was used to prepare ruthenium-palladium / carbon catalysts with ruthenium and palladium loadings of 8.0% and 1.0%, respectively; the catalyst number was CAT-2 / MC.

Embodiment 3

[0055] The same method as in Example 1 was used to prepare ruthenium-palladium / carbon catalysts with ruthenium and palladium loadings of 3.0% and 0.1% respectively; the catalyst number was CAT-3 / MC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com