Preparation method of spongy porous carbon material for supercapacitors

A porous carbon material, supercapacitor technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of not exerting the value of rice husks, pollute the environment, etc., and achieve the effects of being suitable for large-scale industrial production, low energy consumption, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

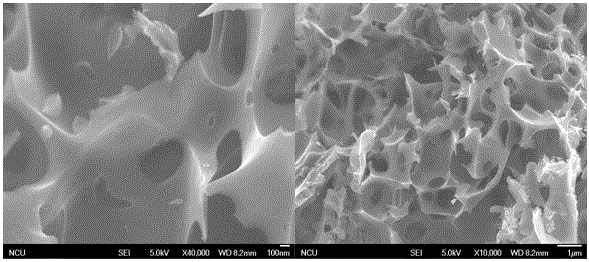

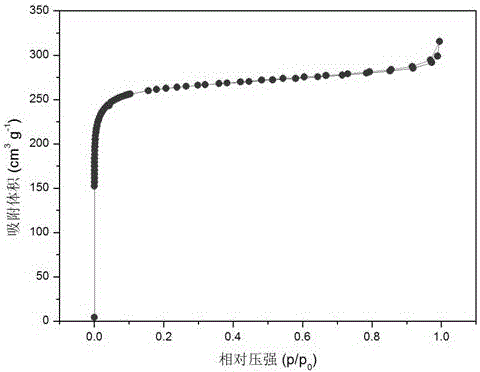

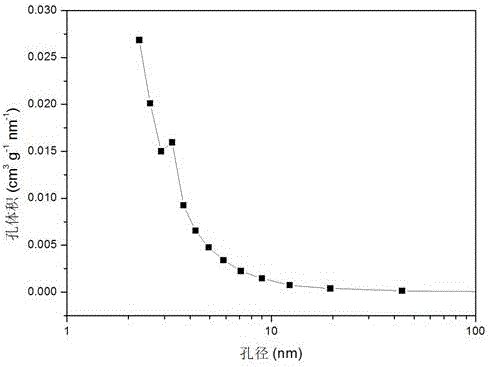

[0028] Soak the washed rice husk in 1mol / L HF solution, keep stirring in a water bath at 80°C for 2 hours, wash it with deionized water until neutral, put it in a 60°C oven and dry it for 24 hours, then KOH and Rice husks were mixed at a mass ratio of 3:1, and appropriate water was added, dried at 60 °C for more than 24 hours, and the dried samples were activated at 700 °C for 1 hour under nitrogen protection, cooled to room temperature with the furnace, and deionized water Wash with 1mol / L dilute hydrochloric acid until neutral, filter, and dry at 60°C to obtain porous carbon.

Embodiment 2

[0030] Soak the washed rice husk in 1mol / L HF solution, keep stirring in a water bath at 80°C for 2 hours, wash it with deionized water until neutral, put it in a 60°C oven and dry it for 24 hours, then KOH and Rice husks were mixed at a mass ratio of 3:1, and appropriate water was added, dried at 60 °C for more than 24 hours, and the dried samples were activated at 800 °C for 1 hour under the protection of nitrogen, cooled to room temperature with the furnace, and deionized water Wash with 1mol / L dilute hydrochloric acid until neutral, filter, and dry at 60°C to obtain porous carbon.

Embodiment 3

[0032] Soak the washed rice husk in 1mol / L HF solution, keep stirring in a water bath at 80°C for 2 hours, wash it with deionized water until neutral, put it in a 60°C oven and dry it for 24 hours, then KOH and Rice husks were mixed at a mass ratio of 3:1, and appropriate water was added, dried at 60°C for more than 24 hours, and the dried samples were activated at 900°C for 1 hour under the protection of nitrogen, cooled to room temperature with the furnace, and deionized water Wash with 1mol / L dilute hydrochloric acid until neutral, filter, and dry at 60°C to obtain porous carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com