Anti-aging coating for automobile body and preparation method thereof

A technology for anti-aging coatings and car bodies, applied in epoxy resin coatings, anti-fouling/underwater coatings, coatings, etc. Improves anti-aging properties and the effect of improving anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

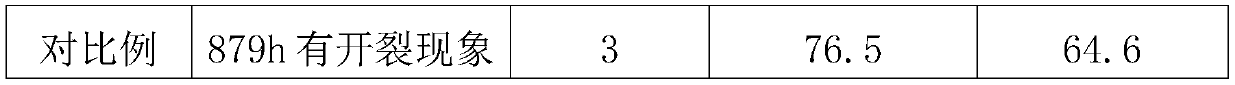

Examples

Embodiment 1

[0027] An anti-aging coating for automobile bodies, which is composed of the following raw material components in parts by mass: 65 parts of polytetrafluoroethylene emulsion, 30 parts of epoxy resin, 15 parts of dicyclohexylmethane diisocyanate, 10 parts of 2,4-diisocyanate Hydroxybenzophenone, 10 parts of triethylenediamine nickel dichloride, 25 parts of ethyl acetate, 11 parts of diatomaceous earth, 8 parts of silane coupling agent KH-550, 12 parts of nano-silica, 6 parts of hollow Glass microspheres, 13 parts of mixed powder, 6 parts of pigment, 2.5 parts of dispersant, 2.6 parts of film-forming aid, 1.8 parts of leveling agent, 1.8 parts of defoamer and 17 parts of deionized water.

[0028] The mixed powder is made by mixing zinc oxide, titanium dioxide and mica powder with a particle size of 100 mesh at a mass ratio of 1:2:1.

[0029] The pigment is zinc phosphate.

[0030] Dispersant selects stearic acid monoglyceride for use.

[0031] The film-forming aid is selected ...

Embodiment 2

[0043] An anti-aging coating for automobile body, which is composed of the following raw material components in parts by mass: 60 parts of polytetrafluoroethylene emulsion, 35 parts of epoxy resin, 13 parts of dicyclohexylmethane diisocyanate, 12 parts of 2,4-diisocyanate Hydroxybenzophenone, 8 parts of triethylenediamine nickel dichloride, 30 parts of ethyl acetate, 9 parts of diatomaceous earth, 10 parts of silane coupling agent KH-550, 10 parts of nano-silica, 7 parts of hollow Glass microspheres, 12 parts of mixed powder, 7 parts of pigment, 2.3 parts of dispersant, 3.0 parts of film-forming aid, 1.5 parts of leveling agent, 2.0 parts of defoamer and 15 parts of deionized water.

[0044] The mixed powder is made by mixing zinc oxide, titanium dioxide and mica powder with a particle size of 150 mesh at a mass ratio of 1:2:1.

[0045] The pigment is titanium dioxide.

[0046] Dispersant selects glyceryl tristearate for use.

[0047] The film-forming aid is selected from et...

Embodiment 3

[0059] An anti-aging coating for automobile body, which is composed of the following raw material components in parts by mass: 70 parts of polytetrafluoroethylene emulsion, 38 parts of epoxy resin, 17 parts of dicyclohexylmethane diisocyanate, 14 parts of 2,4-di Hydroxybenzophenone, 15 parts triethylenediamine nickel dichloride, 32 parts ethyl acetate, 13 parts diatomaceous earth, 11 parts silane coupling agent KH-550, 15 parts nano-silica, 9 parts hollow Glass microspheres, 16 parts of mixed powder, 8 parts of pigment, 3.2 parts of dispersant, 3.2 parts of film-forming aid, 2.5 parts of leveling agent, 2.3 parts of defoamer and 20 parts of deionized water.

[0060] The mixed powder is made by mixing zinc oxide, titanium dioxide and mica powder with a particle size of 170 mesh according to the mass ratio of 1:2:1.

[0061] The pigment is zinc phosphate.

[0062] Dispersant selects stearic acid monoglyceride for use.

[0063] The film-forming aid is selected from dodecyl alco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com