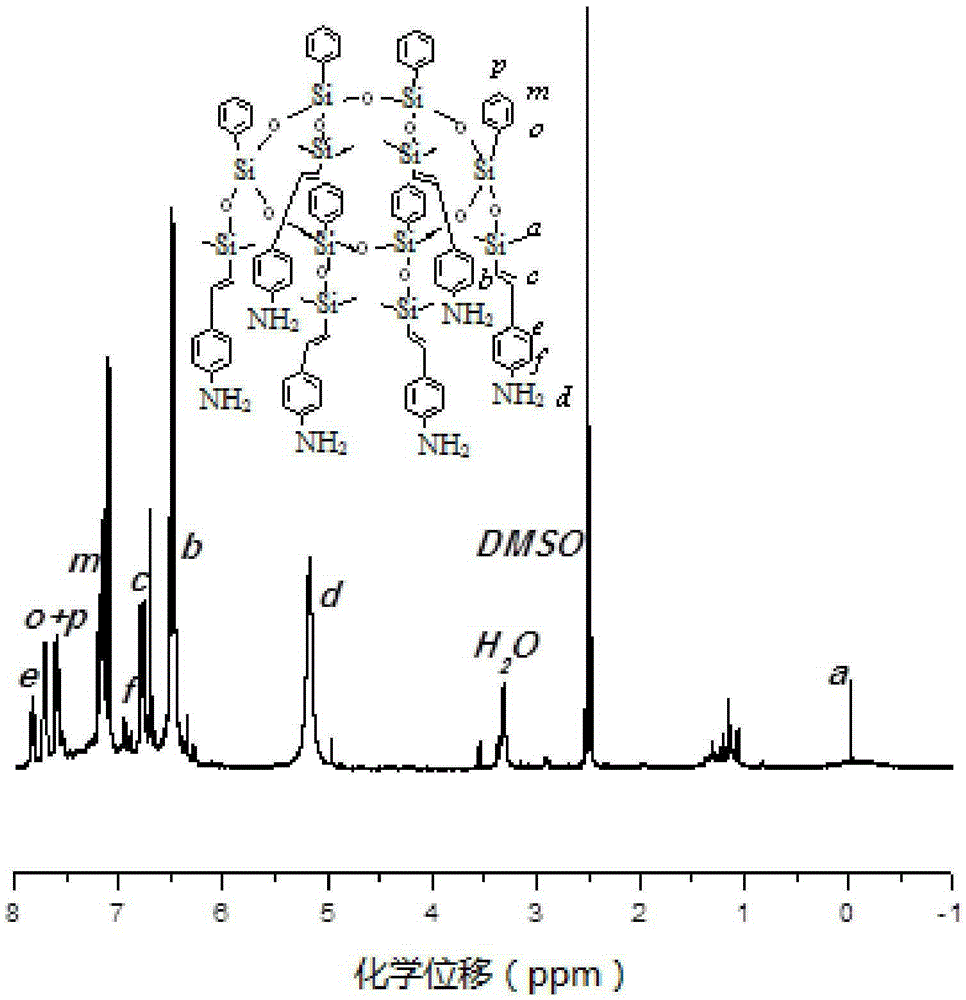

Synthetic method of hexamine phenyl large ring oligomerization silsesquioxane

A technology of polysilsesquioxane and hexaaminephenyl, which is applied in the field of polymer material synthesis to achieve mild reaction conditions, broad application prospects, and extensive functionalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

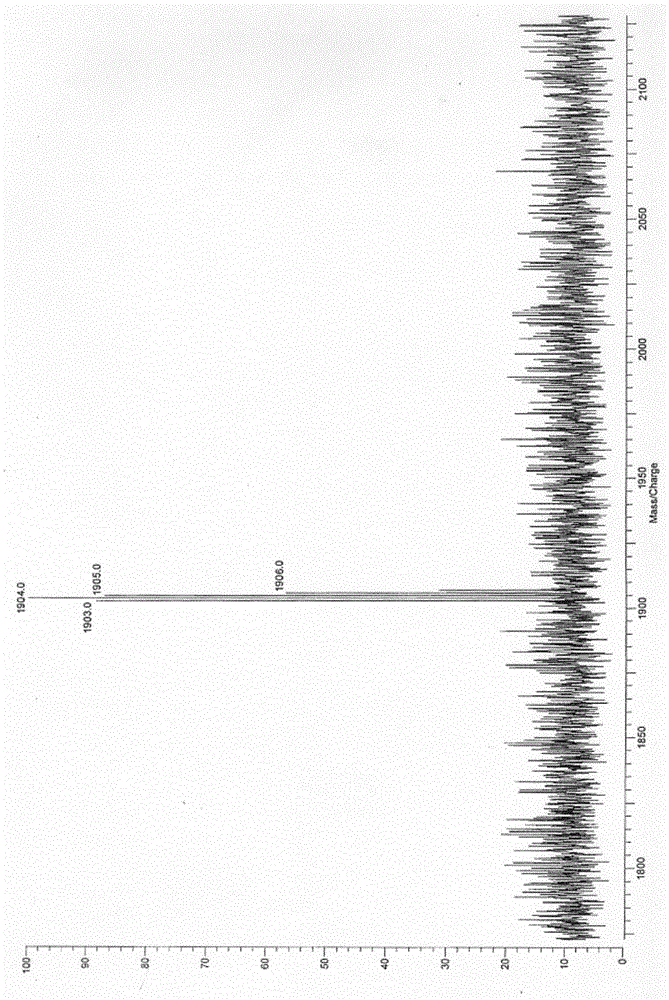

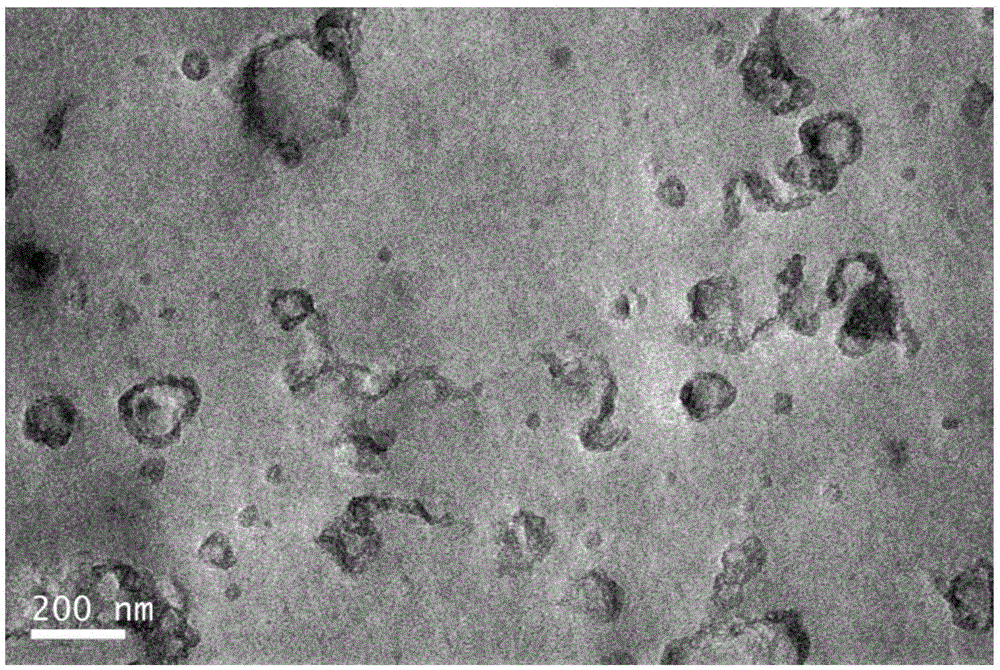

Examples

Embodiment 1

[0038] (1) Preparation of sodium nickel / salt hexasilicate

[0039] 7.7300g of phenyltrimethoxysilane, 1.8000g of NaOH and 0.7000g of H 2 O was added to 130.0000 mL of n-butanol and refluxed for 1.5 hours. After cooling slightly, add 3.0100g hexaamine nickel dichloride at one time, and then reflux for 2 hours. The NaCl salt was filtered off, part of the n-butanol was removed by rotary evaporation, and the orange crystals were precipitated at 0°C overnight. After being obtained by suction filtration, it was vacuum-dried at 80° C. for 1 hour. Weighed 5.4400g, yield 71.8000%.

[0040] (2) Preparation of alkenyl-terminated macrocyclic oligomerized silsesquioxane (hexavinylhexaphenylcyclohexasiloxane)

[0041] 35.0000 mL of dry toluene, 5.5400 mL of dry pyridine and 10.3200 g of vinyl dimethyl chlorosilane were successively added into a 100 mL flask. After 5 minutes, 1.3000 g of sodium / nickel hexaphenylcyclohexasilate was added. After reacting at room temperature for 24 hours,...

Embodiment 2

[0048] (1) Preparation of sodium nickel / salt hexasilicate

[0049] 7.7300g of phenyltrimethoxysilane, 1.8000g of NaOH and 0.7000g of H 2 O was added to 130.0000 mL of n-butanol and refluxed for 1.5 hours. After cooling slightly, add 3.0100g hexaamine nickel dichloride at one time, and then reflux for 2 hours. The NaCl salt was filtered off, part of the n-butanol was removed by rotary evaporation, and the orange crystals were precipitated at 0°C overnight. After being obtained by suction filtration, it was vacuum-dried at 80° C. for 1 hour. Weighed 5.4400g, yield 71.8000%.

[0050] (2) Preparation of alkenyl-terminated macrocyclic oligomerized silsesquioxane (hexavinylhexaphenylcyclohexasiloxane)

[0051] 35.0000 mL of dry toluene, 5.5400 mL of dry pyridine and 10.3200 g of vinyl dimethyl chlorosilane were successively added into a 100 mL flask. After 5 minutes, 1.3000 g of sodium / nickel hexaphenylcyclohexasilate was added. After reacting at room temperature for 24 hours,...

Embodiment 3

[0057] (1) Preparation of sodium nickel / salt hexasilicate

[0058] 7.7300g of phenyltrimethoxysilane, 1.8000g of NaOH and 0.7000g of H 2 O was added to 130.0000 mL of n-butanol and refluxed for 1.5 hours. After cooling slightly, add 3.0100g hexaamine nickel dichloride at one time, and then reflux for 2 hours. The NaCl salt was filtered off, part of the n-butanol was removed by rotary evaporation, and the orange crystals were precipitated at 0°C overnight. After being obtained by suction filtration, it was vacuum-dried at 80° C. for 1 hour. Weighed 5.4400g, yield 71.8000%.

[0059] (2) Preparation of alkenyl-terminated macrocyclic oligomerized silsesquioxane (hexavinylhexaphenylcyclohexasiloxane)

[0060] 35.0000 mL of dry toluene, 5.5400 mL of dry pyridine and 10.3200 g of vinyl dimethyl chlorosilane were successively added into a 100 mL flask. After 5 minutes, 1.3000 g of sodium / nickel hexaphenylcyclohexasilate was added. After reacting at room temperature for 24 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com