Polyolefin material with surface grafted polymer and preparation method and application of polyolefin material

A technology of surface grafting and polyolefin, which is applied in the field of surface-grafting polymer polyolefin material and its preparation, can solve the problems of poor adhesion between modifier and polyolefin, and achieve stable surface performance and low economic cost. , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1) Place 1g of polyethylene powder in a plasma device, and under a vacuum of 200mTorr, pass argon gas into it for glow discharge, adjust the plasma power to 150W, the atmosphere pressure to 250mTorr, and the plasma treatment time for 1min to make the polyethylene powder Generate free radicals on the surface of the material.

[0050] 2) Place the treated polyethylene powder in the air for 30 minutes to convert surface free radicals into peroxides.

[0051] 3) Put 1 g of the treated polyethylene powder and 3 g of hexafluorobutyl acrylate in 3 ml of 1,4-dioxane, blow in an inert gas to remove the air, and put it in an oil bath at 80° C. for 24 hours for polymerization.

[0052] 4) Wash the polymerized product with the solvent 1,4-dioxane to remove unreacted monomers and homopolymers generated by the reaction, and dry it in a vacuum oven at 40°C for 24 hours to obtain a polyethylene surface-grafted polymer. Powder.

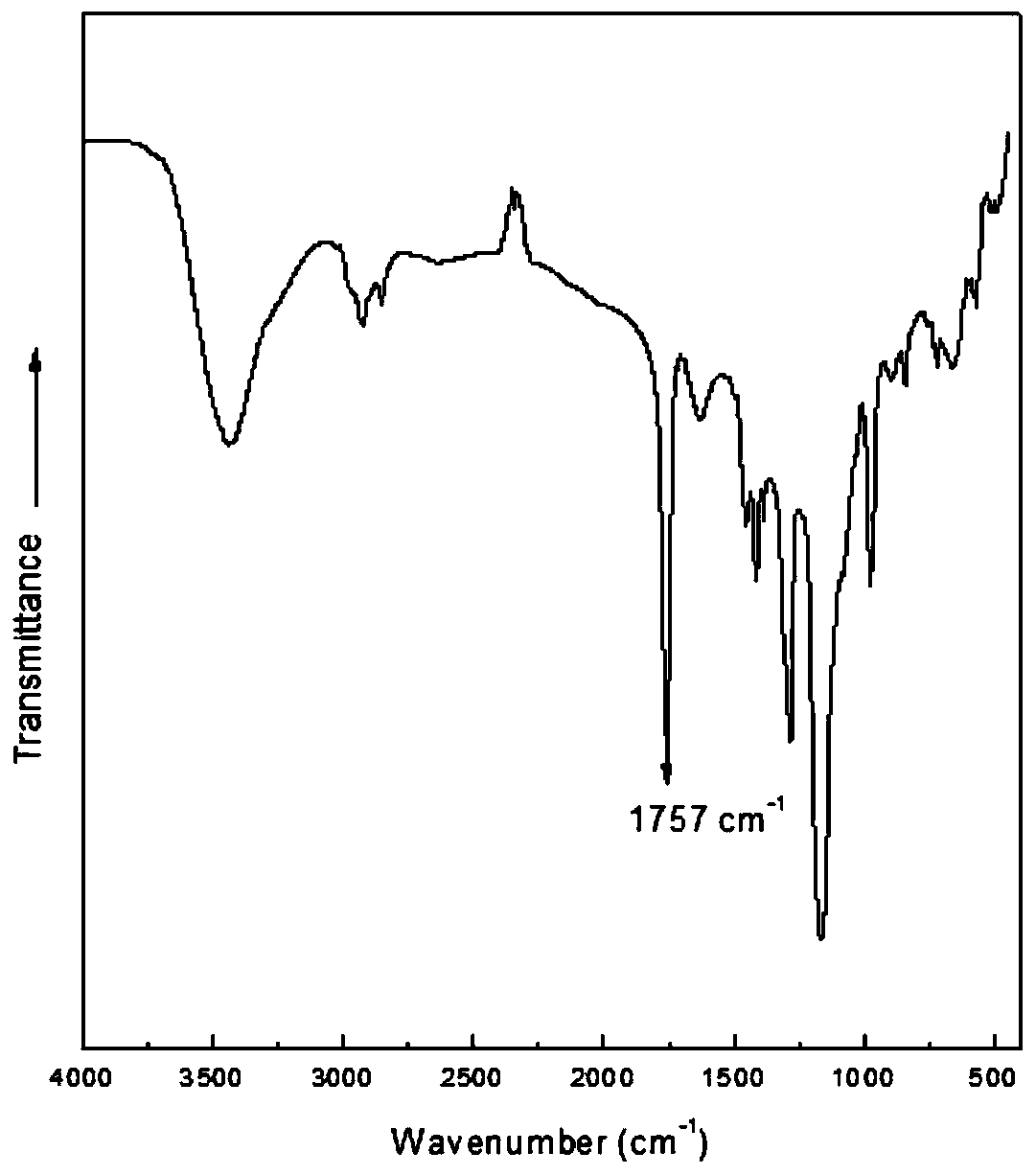

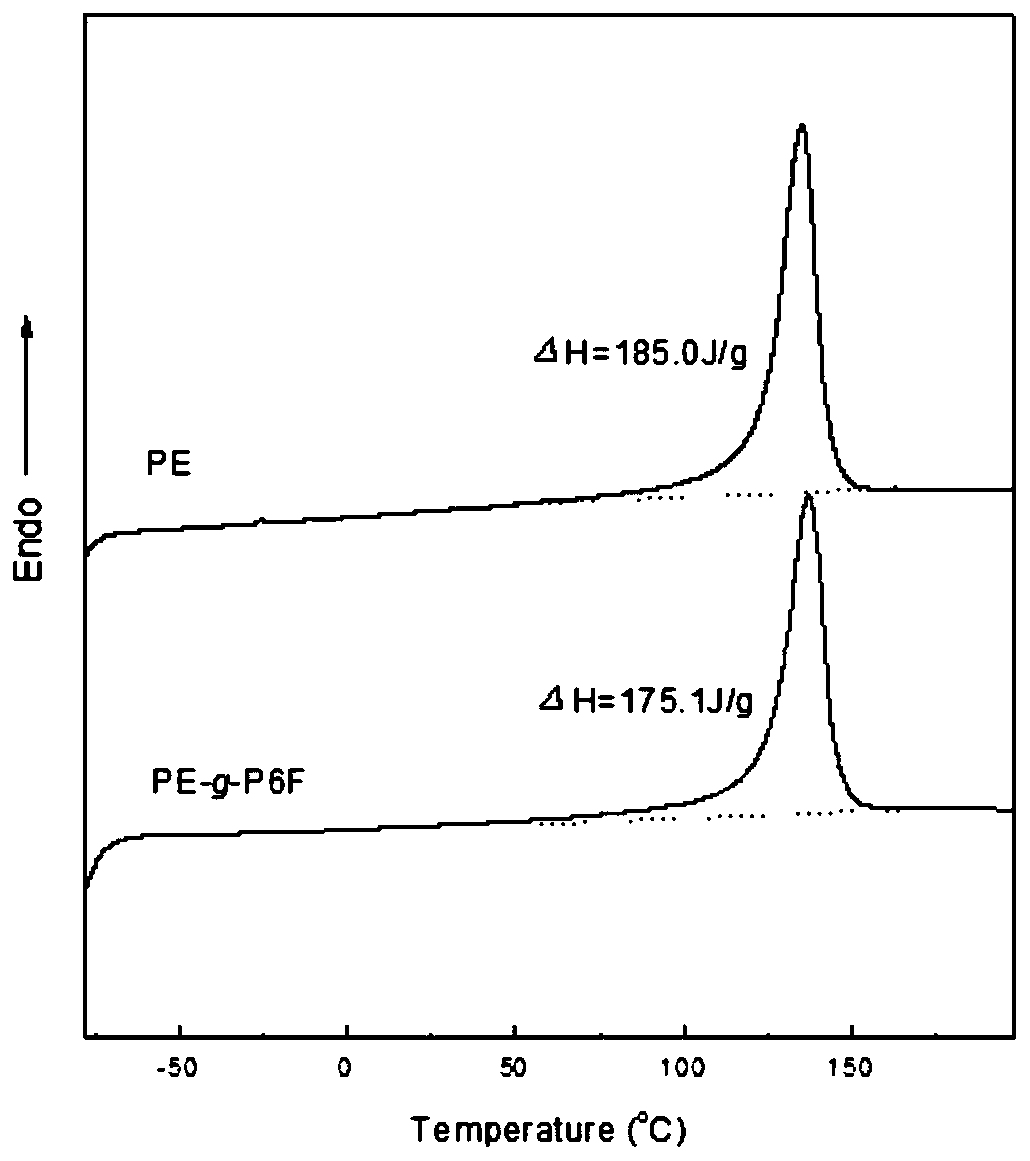

[0053] figure 1 , figure 2 Infrared spectrogram and ...

Embodiment 2

[0056] 1) Place 1 g of polyethylene powder in a plasma device, and under a vacuum of 200 mTorr, pass argon gas into it for glow discharge, adjust the plasma power to 50 W, the atmosphere pressure to 250 mTorr, and the plasma treatment time for 1 min to make the polyethylene powder Generate free radicals on the surface of the material.

[0057] 2) Same as step 2) of Example 1.

[0058] 3) Same as embodiment 1 step 3).

[0059] 4) Same as step 4) of Example 1.

Embodiment 3

[0061] 1) Put 1 g of polyethylene powder in a plasma device, and under a vacuum of 200 mTorr, pass argon gas into it for glow discharge, adjust the plasma power to 100 W, the atmosphere pressure to 250 mTorr, and the plasma treatment time for 1 min to make the polyethylene powder Generate free radicals on the surface of the material.

[0062] 2) Same as step 2) of Example 1.

[0063] 3) Same as embodiment 1 step 3).

[0064] 4) Same as step 4) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com