A single-component polyurea repair method for the surface of hydraulic drainage structures

A technology for drainage structures and repair methods, which is applied in the field of single-component polyurea repair on the surface of hydraulic drainage structures, and can solve the problem of low requirements for bonding performance and anti-abrasion performance, and high requirements for dryness of the base surface , Prone to problems such as bulges and bubbles, achieving the effect of low equipment parameters, easy promotion, and low dryness of the base surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

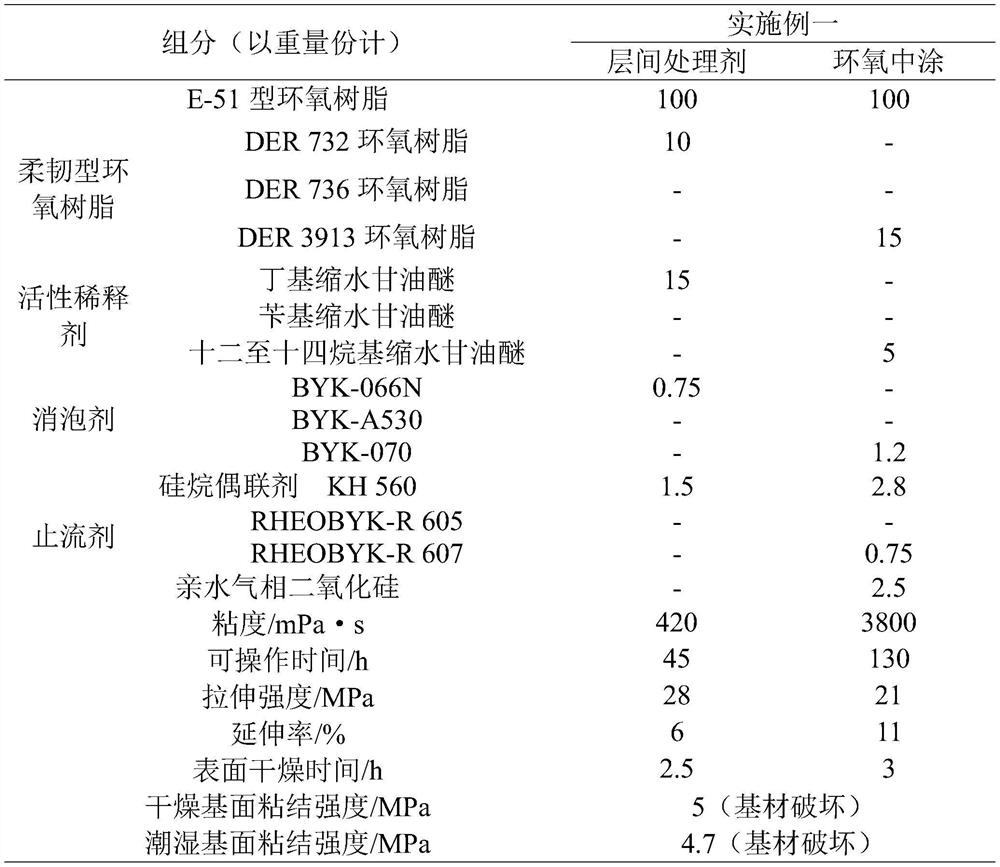

Embodiment 1

[0035] The first step is to rinse with a high-pressure water gun and clean the surface of the old polyurea coating with a brush to remove floating and oily debris. It does not need to be blown dry until there is no flowing water on the surface.

[0036] The second step is to brush the modified epoxy resin interlayer treatment agent on the surface of the first step.

[0037] Wherein, the modified epoxy resin interlayer treatment agent includes A and B components, wherein A component includes: 100 parts by weight of E-51 type epoxy resin; 10 parts by weight of DER 732 epoxy resin; 15 parts by weight of butyl glycidyl ether Parts by weight; 0.75 parts by weight of BYK-066N; 1.5 parts by weight of silane coupling agent (KH 560). Component B is 100 parts by weight of a cardanol-modified phenalkamine curing agent.

[0038] The preparation and application methods of modified epoxy resin interlayer treatment agent are as follows:

[0039] 1): Take the A and B components of the modif...

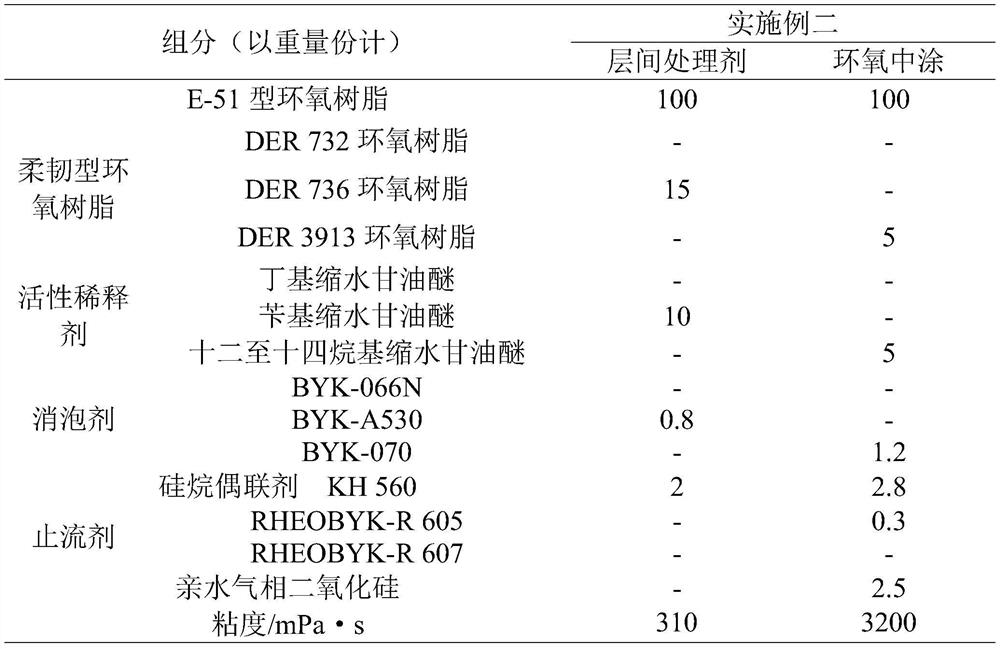

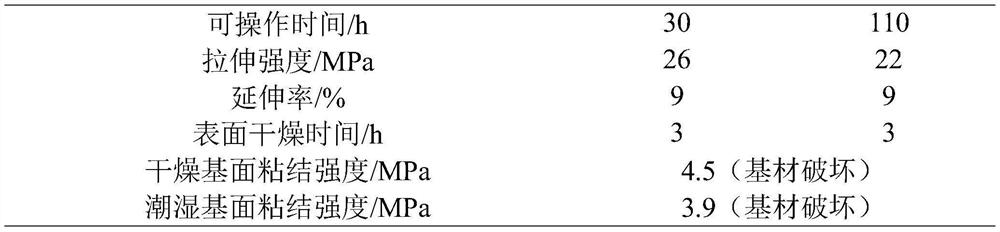

Embodiment 2

[0053] The first step is to rinse with a high-pressure water gun and clean the surface of the old polyurea coating with a brush to remove floating and oily debris. It does not need to be blown dry until there is no flowing water on the surface.

[0054] The second step is to brush the modified epoxy resin interlayer treatment agent on the surface of the first step.

[0055] Wherein, the modified epoxy resin interlayer treatment agent includes A and B components, wherein A component includes: 100 parts by weight of E-51 type epoxy resin; 15 parts by weight of DER 736 epoxy resin; 10 parts by weight of benzyl glycidyl ether parts by weight; 0.8 parts by weight of defoamer (BYK-A530); 2 parts by weight of silane coupling agent (KH 560), and 100 parts by weight of cardanol-modified phenalkamine curing agent for component B.

[0056] The preparation and application methods of modified epoxy resin interlayer treatment agent are as follows:

[0057] 1): Take the A and B components o...

Embodiment 3

[0072] The first step is to rinse with a high-pressure water gun and clean the surface of the old polyurea coating with a brush to remove floating and oily debris. It does not need to be blown dry until there is no flowing water on the surface.

[0073] The second step is to brush the modified epoxy resin interlayer treatment agent on the surface of the first step.

[0074] Wherein, the modified epoxy resin interlayer treatment agent includes A and B components, wherein A component includes: 100 parts by weight of E-51 type epoxy resin; 20 parts by weight of DER 732 epoxy resin; dodecane to tetradecane 15 parts by weight of glycidyl ether; 0.6 parts by weight of defoamer (BYK-A530); 1.8 parts by weight of silane coupling agent (KH 560), and 100 parts by weight of cardanol-modified phenalkamine curing agent for component B.

[0075] The preparation and application methods of modified epoxy resin interlayer treatment agent are as follows:

[0076] 1): Take the A and B component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com