Modified nanometer titanium dioxide photocatalyst, and preparation method and application thereof

A nano-titanium dioxide and photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of limited photocatalytic activity, weak loading force, and reduced Stability and other issues, to achieve high catalytic activity, not easy to lose, and improve the effect of surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

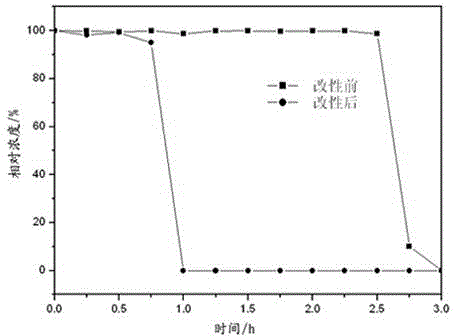

Embodiment 1

[0041] (1) With 100g CCl 4 Add 5.00g nano-TiO to the reactor 2 After the powder is dispersed and stirred uniformly by ultrasound, the temperature is raised to 80°C with stirring; 2.50g PCl 3 Dissolved in 50g CCl 4 In, mixed well, the PCl 3 CCl 4 Add the solution into the reactor, raise the temperature to 90°C after the dropwise addition, and react for 2 hours to remove the CCl in the reaction solution 4 and recycle to obtain a yellow transparent powder, i.e. powder I;

[0042] (2) Add 80g of α-olefin sulfonic acid and 80g of benzene with carbon number of C12-C14 in the reactor successively, stir and heat up to 130°C, take samples and analyze the content of sulfonic acid every 1h, until the content of α-olefin sulfonic acid is constant, The brown liquid phenyl-(dodecyl-tetradecyl)sulfonic acid was obtained; cooled to 10°C, continued to stir, added dropwise 400g of oleum, stirred at room temperature for 2h after the dropwise addition, then added dropwise 240g of 0.2mol L -...

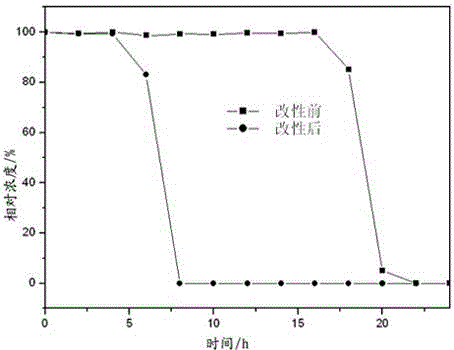

Embodiment 2

[0046] (1) With 85g CCl 4 Add 5.00g nano-TiO to the reactor 2 Powder, after ultrasonic dispersion and stirring, the temperature was raised to 80°C; 2.20g PCl 3 Dissolved in 40g CCl 4 In, mixed well, the PCl 3 CCl 4 Add the solution into the reactor, raise the temperature to 90°C after the dropwise addition, and react for 3 hours to remove the CCl in the reaction solution 4 and recycle to obtain a yellow transparent powder, i.e. powder I;

[0047](2) Add 80g of α-olefin sulfonic acid and 68g of benzene with carbon number of C14-C16 in the reactor successively, stir and heat up to 130°C, take samples and analyze the content of sulfonic acid every 1h, and wait until the content of α-olefin sulfonic acid is constant, The brown liquid phenyl-(tetradecyl-hexadecyl)sulfonic acid was obtained; cooled to 20°C, continued to stir, added dropwise 325g of oleum, stirred at room temperature for 2.5h after the dropwise addition, then added dropwise 190g of 0.2mol L -1 Dilute hydrochlor...

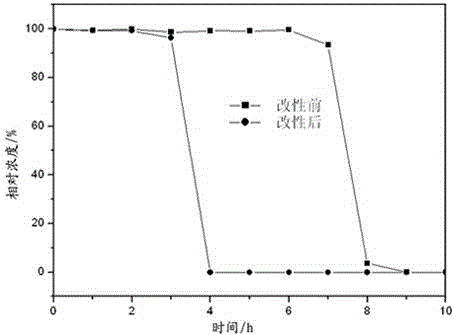

Embodiment 3

[0051] (1) With 65g CCl 4 Add 5.00g nano-TiO to the reactor 2 After the powder is dispersed and stirred uniformly by ultrasound, the temperature is raised to 80°C with stirring; 2.00g of PCl 3 Dissolved in 35g CCl 4 In, mixed well, the PCl 3 CCl 4 Add the solution into the reactor, raise the temperature to 90°C after the dropwise addition, and react for 4 hours to remove the CCl in the reaction solution 4 and recycle to obtain a yellow transparent powder, i.e. powder I;

[0052] (2) Add 80g of α-olefin sulfonic acid and 56g of benzene with carbon number of C16-C18 in the reactor successively, stir and heat up to 130°C, take samples and analyze the content of sulfonic acid every 1h, and wait until the content of α-olefin sulfonic acid is constant, The brown liquid phenyl-(hexadecyl-octadecyl)sulfonic acid was obtained; cooled to 10°C, continued to stir, added dropwise 296g of fuming sulfuric acid, stirred at room temperature for 3 hours after the dropwise addition, and add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com