Method for producing nano nickle sphere

A nano-nickel and preparation method is applied in the field of preparation of nano-nickel balls to achieve the effects of long-term stable existence, good magnetic properties and uniform product morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation of embodiment 1 nano-nickel sphere

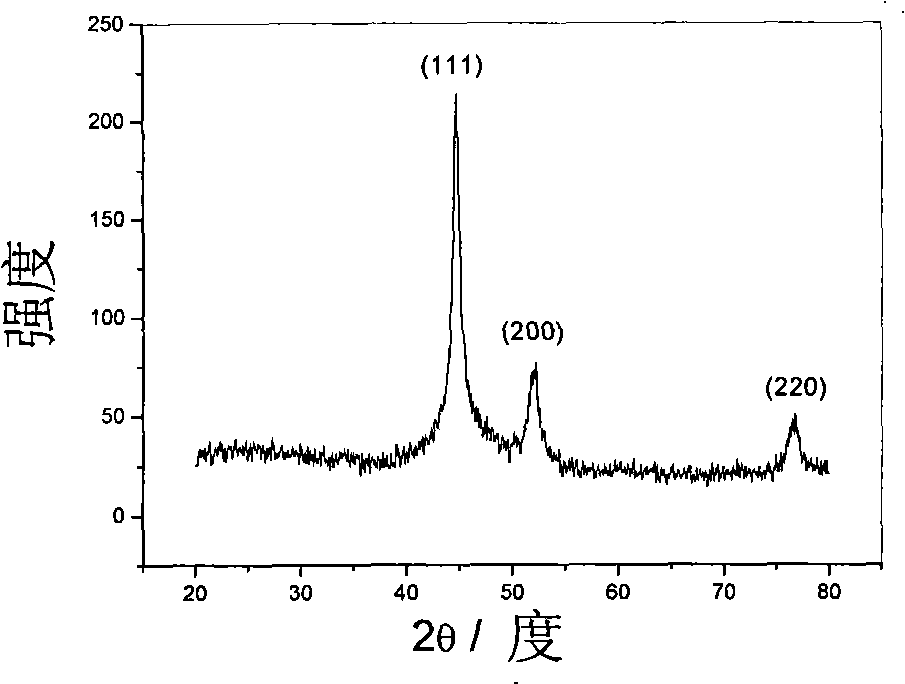

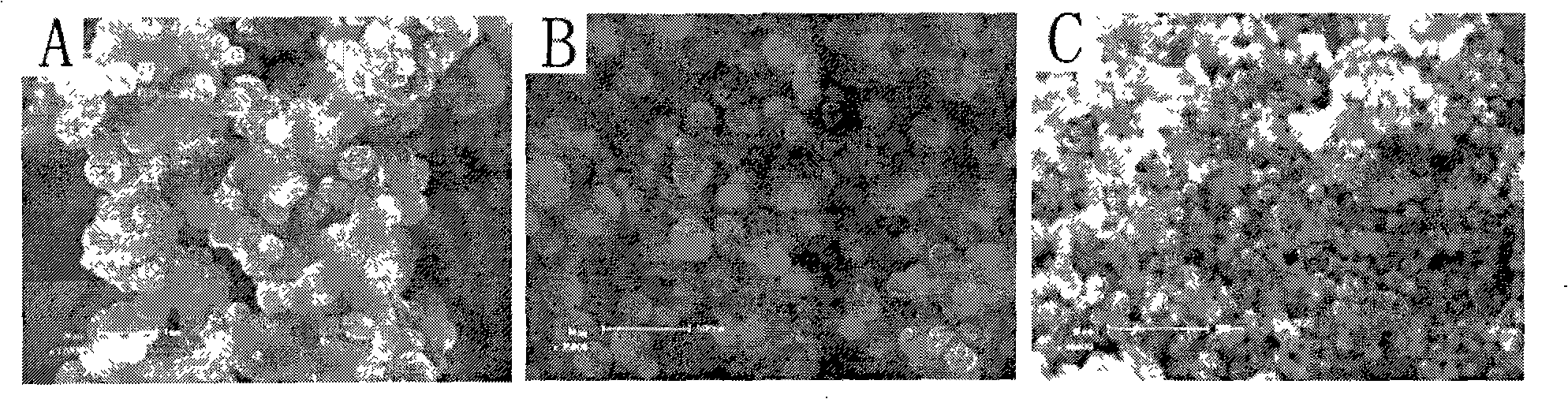

[0020] Weigh nickel chloride (NiCl 2 ·6H 2 O) 0.2g, PVP 0.30g, dissolved in 5ml of water, potassium hydroxide (KOH) 0.27g, sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 0.5g, dissolved in 2ml, 5ml water respectively. Mix nickel chloride, PVP solution and potassium hydroxide solution, and pass nitrogen gas, then add sodium hypophosphite solution and continue nitrogen flow for 10 minutes. The mixed solution was transferred to the inner tank of the hydrothermal kettle with a volume of 15ml, and the nitrogen protection was continued, and then the hydrothermal kettle was sealed, and the reaction was carried out at a temperature of 140°C for 40 minutes. The obtained product was washed three times with water and ethanol respectively, separated magnetically, and finally dried at below 50°C to obtain 0.032 g of black powder. The XRD pattern is shown in Figure 1A , it can be attracted by a magnet (see Figure 1B ). The parti...

Embodiment 2

[0021] The preparation of embodiment 2 nano-nickel spheres (change pH value)

[0022] Weigh nickel chloride (NiCl 2 ·6H 2 O) 0.2g, PVP 0.30g, dissolved in 5ml water, potassium hydroxide (KOH) 0.18g, sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 0.5g, dissolved in 2ml, 5ml water respectively. Mix nickel chloride, PVP solution and potassium hydroxide solution, and pass nitrogen gas, then add sodium hypophosphite solution and continue nitrogen flow for 10 minutes. The mixed solution was transferred to the inner tank of the hydrothermal kettle with a volume of 15ml, and the nitrogen protection was continued, and then the hydrothermal kettle was sealed, and the reaction was carried out at a temperature of 140°C for 40 minutes. The obtained product was washed three times with water and ethanol respectively, magnetically separated, and finally dried at below 50° C. to obtain 0.035 g of black powder. The particle size of the obtained product is 100-300 nanometers, the dispersion is g...

Embodiment 3

[0023] The preparation of embodiment 3 nano-nickel spheres (change pH value)

[0024] Weigh nickel chloride (NiCl 2 ·6H 2 O) 0.2g, PVP 0.30g, dissolved in 5ml water, potassium hydroxide (KOH) 0.09g, sodium hypophosphite (NaH 2 PO 2 ·H 2O) 0.5g, dissolved in 2ml, 5ml water respectively. Mix the nickel chloride solution, the PVP solution and the potassium hydroxide solution, and pass nitrogen gas, then add the sodium hypophosphite solution and continue to pass nitrogen for 10 minutes. The mixed solution was transferred to the inner tank of the hydrothermal kettle with a volume of 15ml, and the nitrogen protection was continued, and then the hydrothermal kettle was sealed, and the reaction was carried out at a temperature of 140°C for 40 minutes. The obtained product was washed three times with water and ethanol respectively, magnetically separated, and finally dried at below 50° C. to obtain 0.036 g of black powder. The particle size of the obtained product is 300-600 nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com