Nickel-doped metal organic framework material and preparation method thereof

A technology of metal-organic frameworks and nickel ions, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of lack of functional groups and adsorption sites, low pollutant adsorption performance, etc., to achieve Improve adsorption effect, increase specific surface area and porosity, and synthesize simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

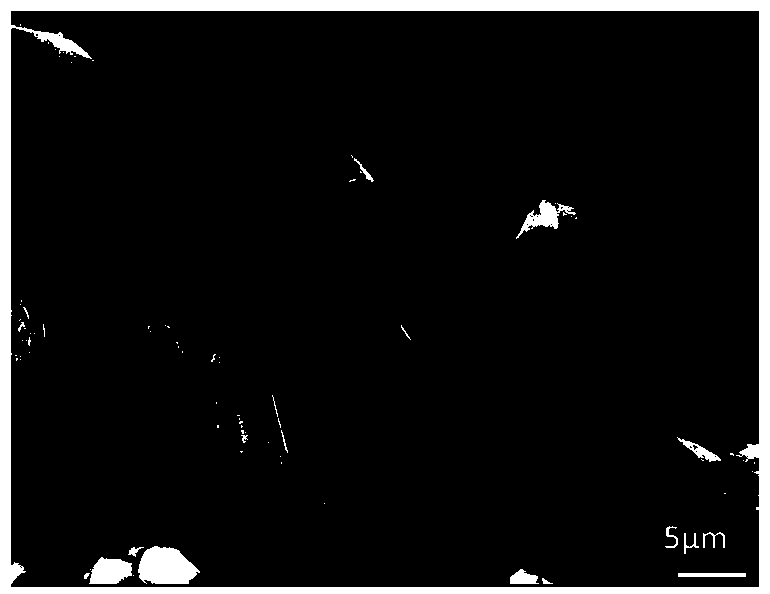

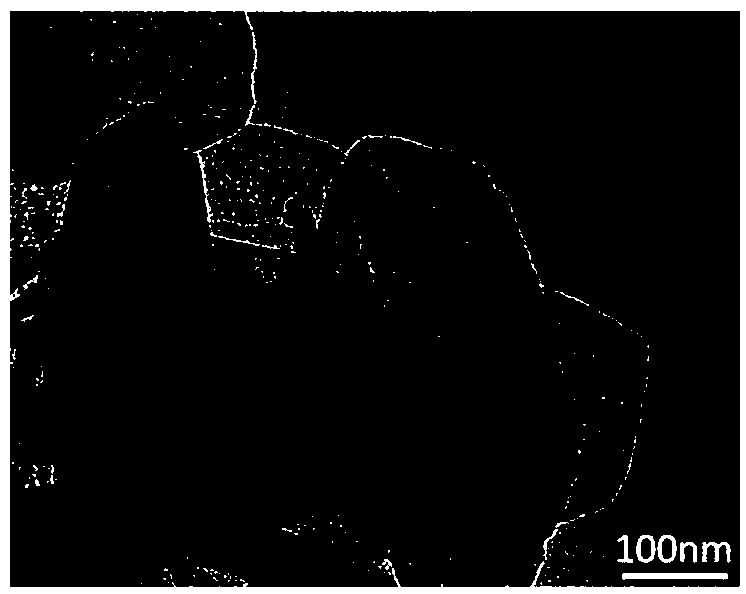

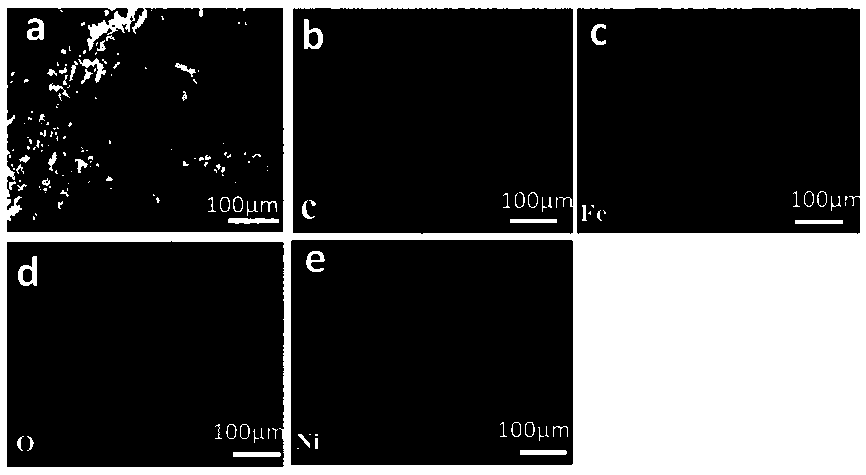

[0028] A nickel-doped metal-organic framework material, including MIL-53(Fe), wherein MIL-53(Fe) is doped with nickel ions.

[0029] In this embodiment, the molar ratio of nickel ions to MIL-53(Fe) is 1:1.

[0030] A method for preparing the nickel-doped metal-organic framework material in the above embodiment, comprising the following steps:

[0031] (1) Weigh ferric chloride hexahydrate, terephthalic acid and nickel chloride hexahydrate and disperse in N,N dimethylformamide (DMF), stir for 3 hours at a speed of 300r / min to obtain a mixed solution ; Wherein, the molar ratio of ferric chloride hexahydrate, terephthalic acid and N,N dimethylformamide is 1:1:56, and the molar ratio of nickel chloride hexahydrate and ferric chloride hexahydrate is 1 : 1.

[0032] (2) Put the mixed solution prepared in step (1) in a reaction kettle lined with polytetrafluoroethylene, and carry out solvothermal reaction at a temperature of 170° C., and the reaction time is 24 hours.

[0033] (3)...

Embodiment 2

[0035] A nickel-doped metal-organic framework material, which is basically the same as the nickel-doped metal-organic framework material in Example 1, except that the molar ratio of nickel ions to MIL-53(Fe) is 1:3.

[0036] A method for preparing the nickel-doped metal-organic framework material in this example is basically the same as that in Example 1, the only difference being: nickel chloride hexahydrate and trichloride hexahydrate in step (1) The molar ratio of iron is 1:3.

[0037] The nickel-doped metal-organic framework material prepared in Example 2 is named Ni-MIL-53(Fe)-3.

Embodiment 3

[0039] A nickel-doped metal-organic framework material, which is basically the same as the nickel-doped metal-organic framework material in Example 1, except that the molar ratio of nickel ions to MIL-53(Fe) is 1:5.

[0040] A method for preparing the nickel-doped metal-organic framework material in this example is basically the same as that in Example 1, the only difference being: nickel chloride hexahydrate and trichloride hexahydrate in step (1) The molar ratio of iron is 1:5.

[0041] The nickel-doped metal-organic framework material prepared in Example 3 is named Ni-MIL-53(Fe)-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com