Method for preparing ultra-fatigue-resisting bionic graphene nano composite material

A nano-composite material and graphene technology, which is applied in the field of preparing super fatigue-resistant biomimetic graphene nano-composite materials, can solve the problem that the dynamic fatigue resistance performance has not been studied and reported, and achieve the effect of excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

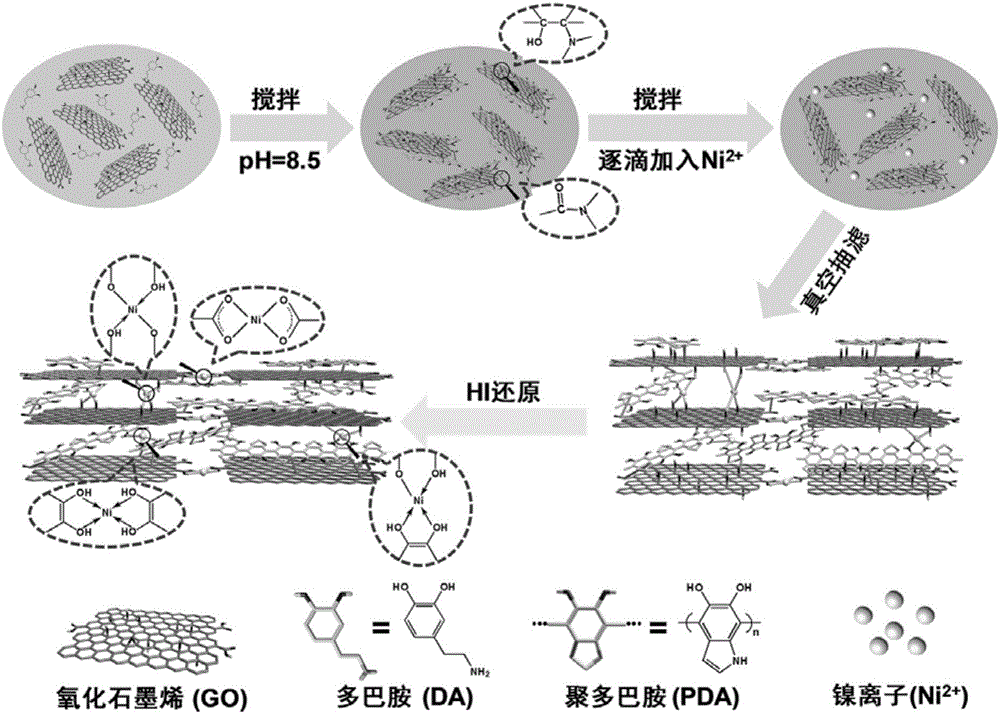

Embodiment 1

[0035] Prepare a 5mg / mL Tris buffer solution in advance: weigh 1.5g of Tris and dissolve it in 50mL of deionized water, then add 0.32mL of concentrated hydrochloric acid, stir for 10min, then add 250mL of deionized water, and then stirred for 10min to obtain a uniform 5mg / mL Tris buffer solution; prepare 2mM NiCl 2 Solution: Weigh 9.5mg of nickel chloride hexahydrate and dissolve it in 20mL of deionized water, stir for 10min to obtain a uniform 2mM NiCl 2 Solution; prepare a 2 mg / mL dopamine solution: weigh 40 mg of dopamine hydrochloride and dissolve it in 20 mL of deionized water, stir for 10 minutes to obtain a uniform 2 mg / mL dopamine solution, which is prepared and used immediately. Then weigh 20 mg of graphene oxide, mechanically stir and disperse in 10 ml of deionized water, and then ultrasonically disperse for 0.5 h to form a brown transparent solution; then, under stirring conditions, add 3 mL of the above tris buffer solution and 0.5 mL of the above dopamine solutio...

Embodiment 2

[0037] Prepare a 5mg / mL Tris buffer solution in advance: weigh 1.5g of Tris and dissolve it in 50mL of deionized water, then add 0.32mL of concentrated hydrochloric acid, stir for 10min, then add 250mL of deionized water, and then stirred for 10min to obtain a uniform 5mg / mL Tris buffer solution; prepare 2mM NiCl 2 Solution: Weigh 9.5mg of nickel chloride hexahydrate and dissolve it in 20mL of deionized water, stir for 10min to obtain a uniform 2mM NiCl 2 Solution; prepare a 2 mg / mL dopamine solution: weigh 40 mg of dopamine hydrochloride and dissolve it in 20 mL of deionized water, stir for 10 minutes to obtain a uniform 2 mg / mL dopamine solution, which is prepared and used immediately. Then weigh 20 mg of graphene oxide, mechanically stir and disperse in 10 ml of deionized water, and then ultrasonically disperse for 0.5 h to form a brown transparent solution; then, under stirring conditions, add 3 mL of the above tris buffer solution and 0.5 mL of the above dopamine solutio...

Embodiment 3

[0039] Prepare a 5mg / mL Tris buffer solution in advance: weigh 1.5g of Tris and dissolve it in 50mL of deionized water, then add 0.32mL of concentrated hydrochloric acid, stir for 10min, then add 250mL of deionized water, and then stirred for 10min to obtain a uniform 5mg / mL Tris buffer solution; prepare 2mM NiCl 2 Solution: Weigh 9.5mg of nickel chloride hexahydrate and dissolve it in 20mL of deionized water, stir for 10min to obtain a uniform 2mM NiCl 2 Solution; prepare a 2 mg / mL dopamine solution: weigh 40 mg of dopamine hydrochloride and dissolve it in 20 mL of deionized water, stir for 10 minutes to obtain a uniform 2 mg / mL dopamine solution, which is prepared and used immediately. Then weigh 20 mg of graphene oxide, mechanically stir and disperse in 10 ml of deionized water, and then ultrasonically disperse for 0.5 h to form a brown transparent solution; then, under stirring conditions, add 3 mL of the above tris buffer solution and 0.5 mL of the above dopamine solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com